Why is electrical steel important in the motor?

Of course the magnetic and mechanical properties of the material are among the more decisive ones. The thinner the material is, the lower will be the eddy-current losses at high frequencies. The efficiency of the motor increases. This in turn means lower electricity consumption and thus higher distance ranges at the same level of battery capacity.An electric machine can only function efficiently when its core is made of soft magnetic material such as electrical steel. Current-carrying coils generate magnetic fields that are amplified many times over by the electrical steel inside the coils, thus making operation of the motor much more efficient. The space inside the coils must be filled as densely as possible with soft magnetic material to ensure this amplification. A massive block of iron could theoretically be used for this purpose but would have the disadvantage of very high power consumption during operation. Stacks of thin, punched sheets are used in order to minimize the consumption of electricity.

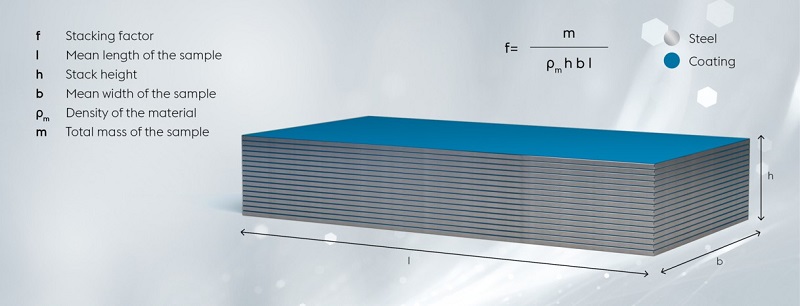

What does the stacking factor entail, and how is it calculated?

The individual sheets are usually coated with an insulating varnish (typically 1–2 µm per side) and feature a certain degree of roughness. When the sheets are stacked and bonded, the stack consists of electrical steel, varnish coating and air inclusions. The ratio between the actual mass of the stack (total mass of the individual laminations) and its theoretical mass (if it were made only of steel) is the stacking factor. This is always less than or equal to 1, since the entire volume is never completely filled with iron.

Pursuant to the DIN EN 60404-13 standard, the stacking factor f is calculated as follows:

A pressure of 1 N/mm2 is exerted on the stack, and the stack height is measured:

A stacking factor of 0.97 means that 97% of the stack consists of electrical steel.

Which variables can influence the stacking factor?

Two variables have a decisive effect on the stacking factor: sheet thickness and coating thickness. Sheet surfaces are not completely smooth and feature a certain degree of roughness. Even when uninsulated material is used, the stacking factor is less than 1 because there are always air pockets between the laminations in the stack. The stacking factor is additionally reduced when coating layer thicknesses increase. The thinner the sheet is, the more pronounced the reduction in the stacking factor will be. The thicker the coating layer is on the strip surface, the less iron there will be in a stack of sheets of a given height. The thinner the electrical steel is, the less advantageous this ratio will become. (The ratio of sheet metal to coating thickness will become smaller and smaller.)

In addition to a high stacking factor, there are a number of other factors that have a positive influence on the performance of electric machines. One of these is the reduction of interlaminar eddy current losses, which is achieved by good electrical insulation between the laminations.

Record Global Stainless Steel Production Forecast for 2019 & 2020

2020-09-30How to "solve" the core loss of electric drive?

2024-06-24Punching technical requirements for iron core

2024-01-04Breaking Through the Bottleneck of High-Frequency Power Equipment: Amorphous/Nanocrystalline Core Technology Ushers in a New Era for Solid-State Transformers

2025-12-01Opportunities and challenges faced by China's stainless steel industry

2022-12-15Application of silicon steel in the field of new energy vehicles

2022-09-26