1. Introduction to Elevator Industry

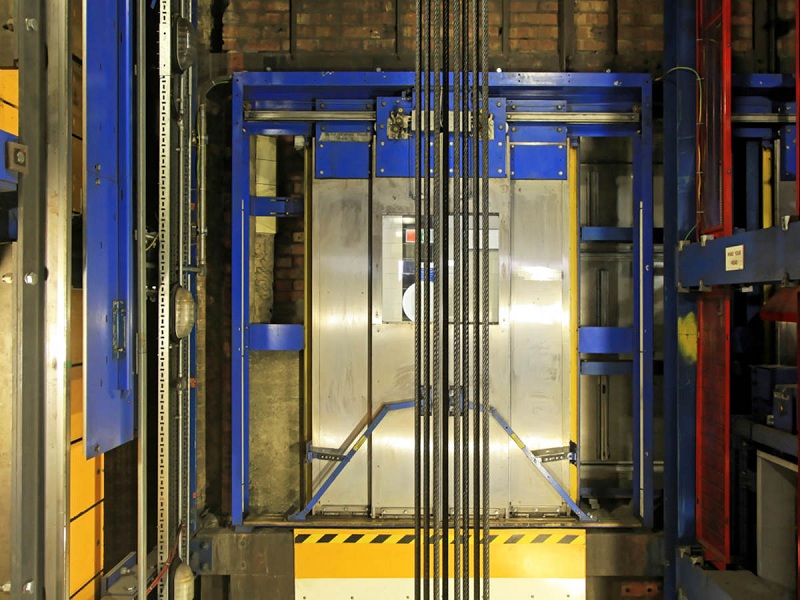

The products produced by the elevator industry include: elevators running vertically, escalators running in inclined direction, moving walks running in inclined or horizontal direction.

Classification of elevators: According to the use, it can be divided into passenger elevators, freight elevators, hospital elevators, sundries elevators, sightseeing elevators, vehicle elevators, ship elevators, construction elevators, and some special-purpose elevators.

2. The Use of Stainless Steel in Elevators Grows

According to industry research, 80% of elevators need to use stainless steel, and the average stainless steel consumption in the industry is 320~350kg per elevator. In 2021, the average stainless steel consumption in the elevator industry will be about 332kg per elevator, with a total consumption of about 513,000 tons.

Thanks to the rapid growth of real estate and infrastructure construction, the consumption of stainless steel in elevator industry has surged after 2018, of which 90,000 tons will increase year-on-year in 2021.

3. Detailed Analysis of Stainless Steel Consumption of Elevators

The types of stainless steel used in the elevator industry are mainly concentrated in 304, 439, 430, 409L, 316L and the current 443 products of the same type. The surface mainly uses HL, NO.4, 2B, BA (polished to 8K) and etching. Product thickness is mainly 0.5 ~ 3.0mm. 0.5, 0.6mm thickness is mainly used in escalator steps; 0.7/0.8/1.2/1.5mm material thickness is mainly used in vertical elevator door panels, vertical elevator car wall panels, escalator exterior decorative panels, baseboards, cover panels, skirt panels, etc. ; 2.0, 3.0mm thickness is used for elevator lift key board, escalator skirt board, etc.

2021.

Products such as SS304, SS439, and SS443 are mainly used in vertical elevator landing doors, vertical elevator car wall panels, escalator retaining walls, and exterior decorative panels. SS304, SS443 are mainly used, SS439 products are used in relatively weak corrosive areas, SS316L is mainly used in areas with harsh corrosive environments; SS430, SS409L products are used in escalator rungs, skirts, cover plates and other parts.

High-quality stainless steel has gradually become the mainstream material for elevator industry decoration. From the price point of view, among several mainstream materials, 304 is the highest, followed by 443 and 430 again. But the reality is that the market share of 304 and 443 is higher than that of 430.

4. The Trend of Demand for Stainless Steel Materials

According to industry research information, the competition of modern elevators is fierce. In recent years, the elevator industry has higher and higher surface requirements for stainless steel materials. In addition to energy saving, elevator development in the future will also develop in the direction of green comfort. The light pollution caused by mirror materials is attracting more and more attention, because the elevator of mirror stainless steel will produce the uncomfortable feeling of "looking in the mirror at the same time". First of all, from the user's point of view, the bidding documents of major project tenders clearly use hairline stainless steel, and more high-end apartments or office buildings are more and more inclined to be treated with color spray painting, etching treatment or matte treatment of stainless steel. Secondly, from the perspective of elevator production, even small elevator companies are increasingly inclined to use stainless steel with brushed hairlines.

Research Team led by Professor Yu Haibin from the Strong Magnetic Field Center Makes New Progress in the Study of Amorphous Material Dynamics and Electronic Structure

2026-01-27Why is the thickness of the same batch of 304 stainless steel belt inconsistent

2024-04-28Jindal Stainless turns to domestic suppliers to cut down on imported raw materials

2020-10-14Classification, application and heat treatment of stainless steel

2023-10-07Thermal deformation structure and behavior of silicon steel

2024-02-20Effect of 304L stainless steel surface drawing oxidation

2024-06-05