Many customers and friends will always encounter the two stainless steel industry terms "normal plate" and "rolled plate" when purchasing stainless steel plates, so what do they mean? Is there any difference?

Normal plate is a cold-rolled product obtained by cold-rolling hot-rolled material; calendered plate is a thinner cold-rolled product that is hot-rolled from cold-rolled material. So what is the difference between them, please see below:

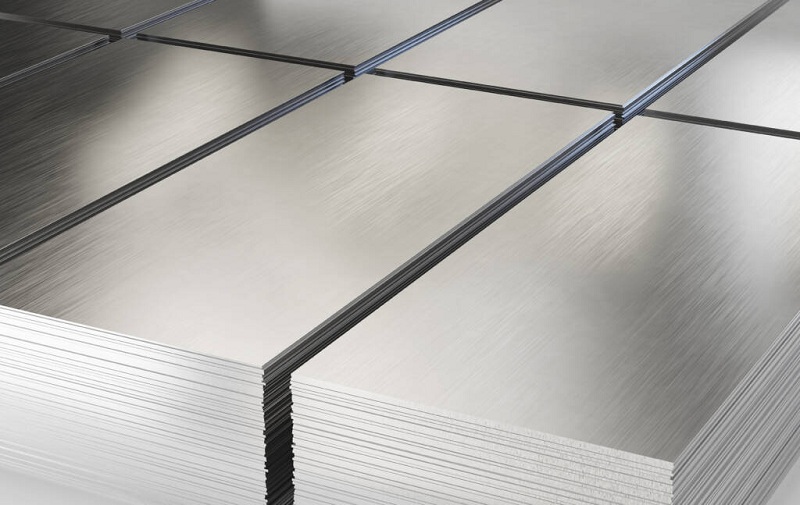

1. Surface

The surface color of the regular board is uniform without dark stripes and roll marks, while the surface of the calendered board often has dark or yellow stripes, accompanied by peeling, water marks and other bad surfaces. Therefore, when purchasing calendered sheets, be sure to check its surface carefully. However, it is reported that with the improvement of production technology and production technology, the gap between normal material plate and calendered plate is gradually narrowing.

2. Thickness

The thickness of the normal material board is made according to the regulations, and the calendered board is customized according to the needs of customers. Sometimes there will be uneven thickness, such as the calendered board is thick in the middle but thin on both sides. This is generally not the case with normal boards.

3. Surface effect

There are basically no problems on the surface of the calendered plate after frosting and 8K surface treatment.

4. Application

Due to the flexible operation of the calendering plant, the width and thickness of the product can be freely pressed according to the customer's requirements.In this way can reduce the waste generated in the production of stainless steel products and save costs and materials. It is often used for products that require matte or 8K surfaces.

Application of stainless steel in various industries

2021-05-20Research Team led by Professor Yu Haibin from the Strong Magnetic Field Center Makes New Progress in the Study of Amorphous Material Dynamics and Electronic Structure

2026-01-27The kitchen should be made of stainless steel sheets,is it good enough? Listen to the truth~

2021-10-22Where is the application field of 316L stainless steel pipe drawing technology?

2021-03-10Analysis on Silicon Steel Sheet of Brushless Motor

2023-08-07Mirror Stainless Steel Grinding and Polishing

2021-08-03