What is Steel Pipe Dimensions Schedule?

Steel pipe schedule is a indicating method represented by ASME B 36.10, and also used in many other standards, marked with “Sch”. Sch is the abbreviation of schedule, generally appearing in the American steel pipe standard, which is a prefix of a series number. For example, Sch 80, 80 is a pipe number from chart/table ASME B 36.10.

“Since the steel pipe main application is to transport the fluids under pressure, so their internal diameter is their critical size. This critical size is taken as nominal bore (NB). Therefore, if steel pipe carry the fluids with pressure, it is very important that pipe shall have enough strength and enough wall thickness. So wall thickness is specified in Schedules, which means the pipe schedule, abbreviated as SCH. Here ASME is the given standard and definition for the pipe schedule.”

The pipe schedule formula:

Sch.=P/[ó]t×1000

P is the Designed pressure, units in MPa;

[ó]t is Allowable stress of materials under design temperature, Units in MPa.

What does SCH mean for the steel pipe dimensions

As describing the steel pipe parameter, we usually use the pipe schedule, It is a method that represent pipe wall thickness with number. Pipe schedule ( sch. ) is not a wall thickness, but a wall thickness series. Different pipe schedule means different wall thickness for the steel pipe in the same diameter. The most frequently indications of schedule are SCH 5, 5S, 10, 10S, 20, 20S, 30, 40, 40S, 60, 80, 80S, 100, 120, 140, 160. The larger the table number, the thicker the surface pipe wall, the higher the pressure resistance.

Schedule 40, 80 steel pipe dimension means

If you are new in pipe industry, why you always see a schedule 40 or 80 steel pipe everywhere? What kind of material for these pipes?

As you have read above articles you know that Schedule 40 or 80 represent a pipe wall thickness, but why it always been searched by buyers?

Here is the reason:

Schedule 40 and 80 steel pipe as the common sizes that required in different industries, because of the generally pressure these pipes bear, they are always been asked for a large quantity.

The material standard for such thickness pipes has no limitations, you could ask sch 40 stainless steel pipe, like ASTM A312 Grade 316L; Or sch 40 carbon steel pipe, such as API 5L, ASTM A53, ASTM A106B, A 179, A252, A333 etc..

What is DN (Nominal Diameter)

Both ASME B36.10 and B36.19 are the standard specification for the dimensions of the steel pipe and accessories.Nominal diameter also mean outside diameter. Because as the pipe wall is very thin, the outside and inside diameter of the steel pipe is almost same, so the average value of the both parameters is used as the name of the pipe diameter. DN (nominal diameter) is the general diameter of various pipe and pipeline accessories. The same nominal diameter of the pipe and pipe fittings can be interconnected, it has interchangeability. Although the value is close or equal to inside diameter of pipe, It is not the actual sense of the pipe diameter. The nominal size is represented by a digital symbol followed by the letter “DN”, and mark the unit in millimeters after the symbol. For example, DN50, a pipe with a nominal diameter of 50 mm.

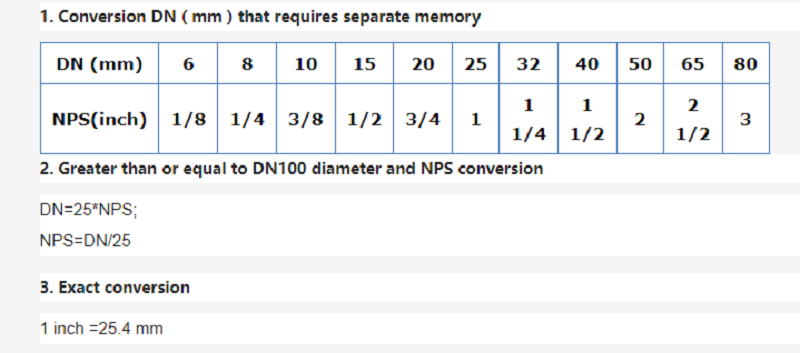

DN (mm) and NPS (inch) conversion

Nominal diameter DN (mm) and NPS (inch) conversion

Pipe Weight Class Schedule

WGT class (weight class) is an indication of the pipe wall thickness in early, but still used. It has only three grades, namely STD ( standard ), XS ( extra strong ), and XXS ( double extra strong ).

For the earlier production pipe, each caliber has only one specification, called standard tube (STD). In order to deal with high pressure fluid, the thickening pipe (XS) appeared. XXS ( double extra strong ) pipe appeared to handle the higher pressure fluid. People began to require the use of more economical thin-walled pipe until the emergence of new materials processing technology, then gradually appeared the above pipe number. The corresponding relation between pipe schedule and weight class, refer to ASME B36.10 and ASME B36.19 specification.

How to describe steel pipe dimensions and size correctly?

b. Expressed as “NPS x Schedule”, NPS 3 inch x Sch 40, NPS 4 inch x Sch 40. Same size as above specification.

c. Expressed as “NPS x WGT Class”, NPS 3 inch x SCH STD, NPS 4 inch x SCH STD. Same size above.

d. There is another way, in North America and South America, usually use “Pipe Outer Diameter x lb/ft” to describe pipe size. As OD 3 1/2”, 16.8 lb/ft. lb/ft is pound per feet.

Classification of stainless steel checkered plates

2022-09-19In-depth Analysis of Technical Trends and Overseas Opportunities for Silicon Steel

2025-11-06Stainless Steel Use In Marine Applications

2023-04-10What are the advantages of stainless steel flower pots?

2022-08-16Application of multi-air gap segmented core in anti-dc bias transformer

2025-03-11Influence of silicon steel material on transformer performance

2024-11-22