The stainless steel checkered plate is embossed on the stainless steel plate by mechanical equipment, so that the surface of the plate has a concave and convex pattern. In the early 1960s, it was produced in small batches by large mills in Europe, and then became popular due to the excellent corrosion resistance and slip resistance of stainless steel checker plates, which were adopted by many industries.

The pattern of the earliest stainless steel checker plate is horizontal and vertical stripes. In the following 20-30 years, after continuous experiments and improvements, researchers designed patterns with better slip resistance, and promoted and applied them on a large scale. In recent years, the use of stainless steel checker plate has been constantly innovating, breaking through and changing. The applicable industries and product models are also increasing, and the speed of product replacement is also more frequent.

Stainless steel checker plate is divided into two categories:

One is rolled by a mill in the production of stainless steel by a steel mill. The thickness of this type of product is about 3-6mm, and it is in the state of annealing and pickling after hot rolling.

This type of checker plate is flat on back side and patterned on the other side. This kind of checker plate is more commonly used in chemical, railway vehicles, platforms and other occasions where strength is required.

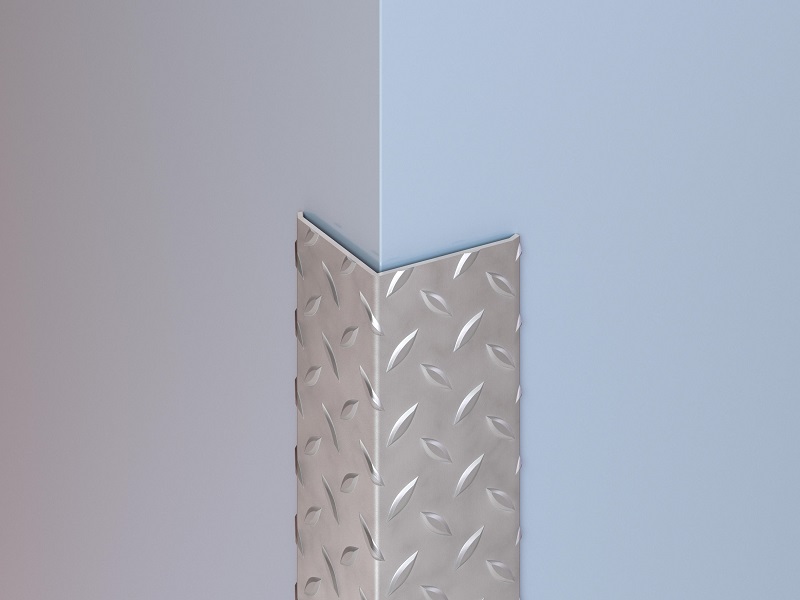

The second category is the checker plate made by processing enterprises in the market to purchase hot-rolled or cold-rolled stainless steel plates from mills and stamped by machinery. These products are concave on one side and convex on the other, and are often used in general civil decoration occasions. There are many cold-rolled products of this type, and most of the 2B/BA cold-rolled stainless steel checker plates on the market are of this type.

With more and more scientific research investment and development, the international use of stainless steel checker plate is no longer limited to the professional fields and industrial applications of anti-skid and anti-corrosion. Stainless steel checkered plates are more innovatively used in building curtain walls, decoration, rail transit, machinery manufacturing and other industries. And derived from square, diamond, leather, ceramic tile, stone brick, ripple and so on more than 20 kinds of products of international general specifications. On the basis of the above products, new products such as coloring, coating, composite, nano-film, super anti-corrosion, anti-bacterial, anti-wear stainless steel checker plate are also constantly meeting the needs of human high-quality life and industry innovation.

Properties and applications of electrical steel stainless steel tubes

2023-11-25The difference between stainless steel and carbon steel

2021-08-18The distinction between hot rolled steel and cold rolled steel

2023-08-30How to distinguish 304 stainless steel sheet and 201 stainless steel sheet?

2021-01-13The application of 304 stainless steel in daily life

2022-04-24What do the "normal plate" and "rolled plate" of stainless steel mean? How to distinguish them?

2022-11-18