People always confused about how to describe steel pipe dimensions (sizes) in correct ways, or how to clarify to seller what exactly pipe size we are going to purchase. In case any misunderstandings or a different size we purchased, that will be a big trouble.

So, what are the exactly right ways to express the steel pipe dimensions?

For your better understanding, we will explain from below aspects:

3 characters for a pipe dimension

Dimension Standards of carbon and stainless steel pipe (ASME B36.10M & B36.19M)

Pipe Size Schedule (Schedule 40 & 80 steel pipe means)

Means of Nominal Pipe Size (NPS) and Nominal Diameter (DN)

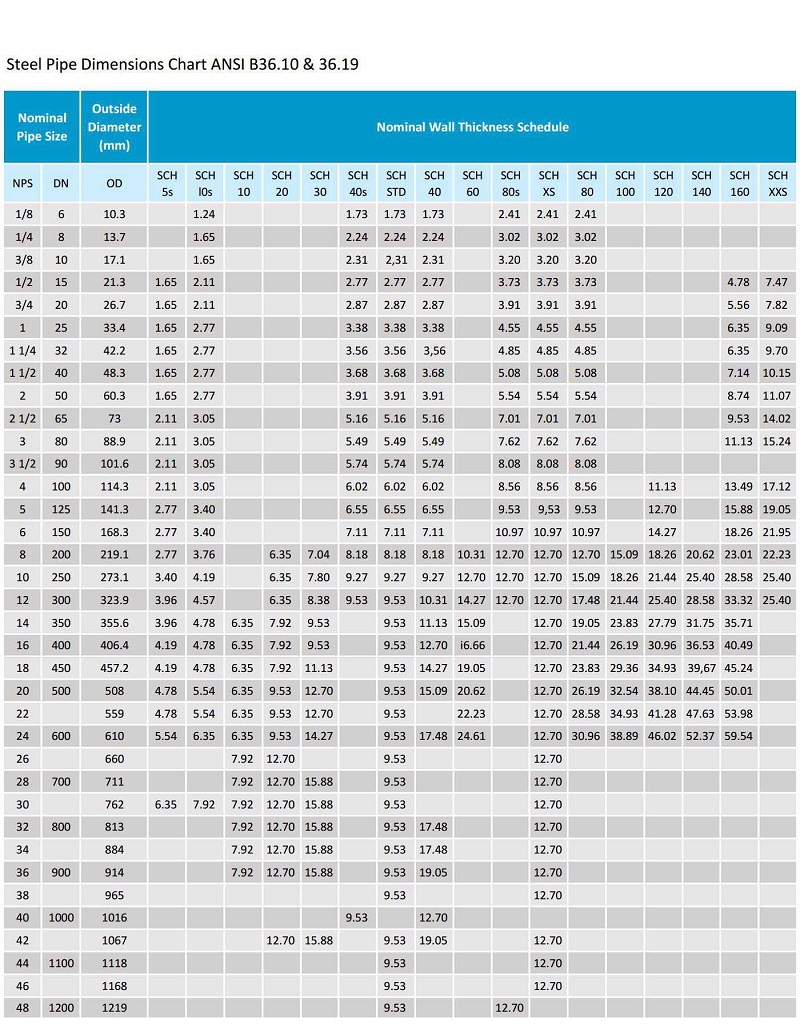

Steel Pipe Dimension Chart (Size chart)

Pipe Weight Class Schedule (WGT)

And finally, we will tells you how to describe steel pipe dimensions & sizes correctly.

Steel Pipe Dimension 3 characters

A completely description for steel pipe dimension includes outer diameter (OD), wall thickness (WT), pipe length (Normally 20 ft 6 meter, or 40 ft 12 meters).

Through these characters we could calculate the pipe weight, how much pressure pipe could bear, and the cost per foot or per meter.

Therefore, that’s why we always need to know a right pipe size.

Steel Pipe Dimensions Chart (Size Chart)

Pipe Schedule Chart unit in mm as below, view here for Pipe Schedule Chart in inch.

There are different standards to describe the steel pipe size, OD and wall thickness. Mainly are ASME B 36.10, ASME B 36.19.

Relevant standard specification ASME B 36.10M and B 36.19M

Both ASME B36.10 and B36.19 are the standard specification for the dimensions of the steel pipe and accessories.

ASME B36.10M

The standard covers the standardization of steel pipe dimensions and sizes. These pipes includes seamless or welded types, and applied in high or low temperature and pressures.

The pipe distinguished from tube (Pipe vs Tube), here the pipe is specially for pipeline systems, fluids (Oil and gas, water, slurry) transmissions. Use the standard of ASME B 36.10M.

In this standard, the pipe Outer Diameter smaller than 12.75 in (NPS 12, DN 300), pipe actual diameters is larger than NPS (Nominal Pipe Size)or DN (Nominal Diameter).

On the hand, for steel tube dimensions, the actual outside diameter same with pipe number for all sizes.

Why pipe size smaller to NPS 12 (DN 300) have different OD

First, we need to admit that all pipe size should be identified as nominal pipe size (NPS).

Second, for NPS 1/8 (DN 6) to NPS 12 (DN 300), these are based on a standard outside diameter (O.D.) This O.D. was originally selected to specify pipe dimension, but as the pipe always have an wall thickness and internal diameter (ID). For small pipe, there is a different size between OD and ID (Wall thickness), but as the pipe dimensions became larger, the OD and ID approximately to become equal.

As there is no such relation between the old standard thickness (O.D.) and Nominal Size, so both of them accepted by standard ASME B 36.10 M.

Steel Pipe Schedule

In ASME B36.10M, Pipe schedule identified as Standard (STD), Ex-Standard (XS), or Double Extra Strong(XSS); Or with Schedule No. 5, 10, 20, 30, 40, 80, 120, 160.

ASME B36.19M

ASTM B36.19M is for the stainless steel pipe dimensions, included seamless and welded types as the same.This dimension standard mostly is same with ASTM B36.10M. Wherever the different part is:

a. For NPS 14 to NPS 22 (DN 350-550), schedule 10S;

b. NPS 12 of Schedule 40S

c. NPS 10 and 12 of schedule 80S.

Above mentioned pipe thickness is different with B36.10M, so suffix “S” is used here.

Ways of express pipe dimensions

1. For Pipe wall thickness: Use Steel Pipe Schedule, like schedule 40 steel pipe, schedule 80 pipe.

2. For pipe Diameters: Nominal Pipe Size (NPS) and DN (Nominal Diameter)

3. Pipe weight Class (WGT), LB/FT (Pounds per foot), KG/M (Kg per meter)

Metal on metal tends to be loud. If you’re sensitive to loud noises, stainless steel might not be the best option.

Research on the development trend of thin gauge silicon steel

2024-03-04Ideal For Bikes Brake Discs - Stainless Steel

2023-02-20New opportunities and challenges in stainless steel industry

2024-04-19Regarding the motor, I have a few more points to add

2023-02-13Hongwang Random grain stainless steel,showing spirit of contemporary art

2023-04-282,700 Tons Steel Transported from Ningxia to Countries along “Belt and Road”

2020-11-09