Heat treatment process is one of the important technology in the process of electrical steel processing, and the heat treatment process greatly affects the magnetic properties of electrical steel products. electrical steel is actually an iron-silicon alloy, and the heat treatment of electrical steel is a discipline that studies the relationship between the properties of electrical steel and heating temperature, time and the atmosphere in the furnace and the cold zone. Therefore, it can be said that the heat treatment of electrical steel is the process of changing the organizational structure of electrical steel under the action of heating, insulation, cooling and the atmosphere in the furnace, so as to obtain the required performance.

In addition to the normal annealing of the hot rolled coil, the cold-rolled electrical steel strip also needs to undergo various forms of heat treatment several times after cold rolling. Intermediate decarburization annealing, work hardening elimination annealing, magnesium oxide isolation coating drying treatment, high temperature circular furnace and shroud furnace annealing, tensile heat leveling annealing, finished product annealing and insulation layer drying sintering treatment.

The soft magnetic materials used at the end of the 19th century mostly use industrial pure iron, the iron loss of its core, after adding a small amount of silicon, can improve the magnetic induction, and the iron loss is greatly reduced. It has been found that silicon plays a decisive role in the level of magnetic induction, which is because: the value is very large, the magnetic induction is below 10000 Gauss, and the core loss value is 3-6W /kg. Therefore, the generators, motors and transformers produced are large in volume, poor in quality and low in efficiency. It was later found that after adding a small amount of silicon, the magnetic induction can be improved, and the iron loss is greatly reduced. It is found that silicon plays a decisive role in the level of magnetic inductance, because: silicon can improve the magnetic permeability, reduce coercivity, reduce hysteresis loss; At the same time, silicon can also promote the graphitization of carbon and reduce the harmful effects of carbon on magnetism. Due to the above effects of silicon, iron-electrical alloys are now widely used in the electric motor, transformer and communication industries. The electrical steel sheet usually used is Fe-Si binary alloy, and other impurities are few.

Therefore, the amount of Si increases, the iron loss decreases, and the magnetic sensitivity increases, but the brittleness increases, the processing is difficult, and the molding is difficult. Generally, the silicon content of silicon-free electrical steel is below 0.3%, the silicon content of low silicon electrical steel is 0.3-0.8%, the silicon content of medium electrical steel is 0.8-2.4%, and the silicon content of high electrical steel is within 2.5-3.4%.

Silicon has a great influence on the properties of iron-silicon alloys, and even a small amount of silicon can significantly change the physical and mechanical properties of iron-silicon alloys. The addition of silicon to iron can improve the hardness and strength, while the elongation and impact toughness will be reduced, silicon is particularly sensitive to brittleness, resulting in great difficulties in processing.

The Si content of cold-rolled electrical steel sheet is generally below 3.5%, the higher the Si content, the greater the brittleness, the more difficult the rolling molding. The Si content of hot-rolled electrical steel sheet is generally less than 5%. This is because the plasticity of Fe-Si alloy is closely related to temperature, such as electrical steel with Si content of 4.5% is very brittle at room temperature, but it can be rolled when heated to about 100 ° C. When producing electrical steel sheets, in the final annealing of magnetic play, if the temperature range of the γ phase is annealed, the magnetic properties will be deteriorated. Cold-rolled non-oriented electrical steel sheets rely on continuous annealing of time to make it magnetic, but the higher the silicon content of the electrical steel, the more able to be annealed at high temperature, so the oriented electrical steel sheets rely on high temperature for a long time to annealing in the ring furnace or shield furnace to make it magnetic, so the silicon content of the oriented electrical steel must be greater than 2.5%.

Why does stainless steel rust?

2021-06-11The five famous stainless steel buildings you should know.

2022-12-19Why are there holes in the stainless steel chairs in the railway station?

2022-01-04The status of colored stainless steel decorative sheets in decorative materials

2020-11-26Research Progress in Hierarchically Heterogeneous 316L Stainless Steel by Additive Manufacturing at Institute of Mechanics

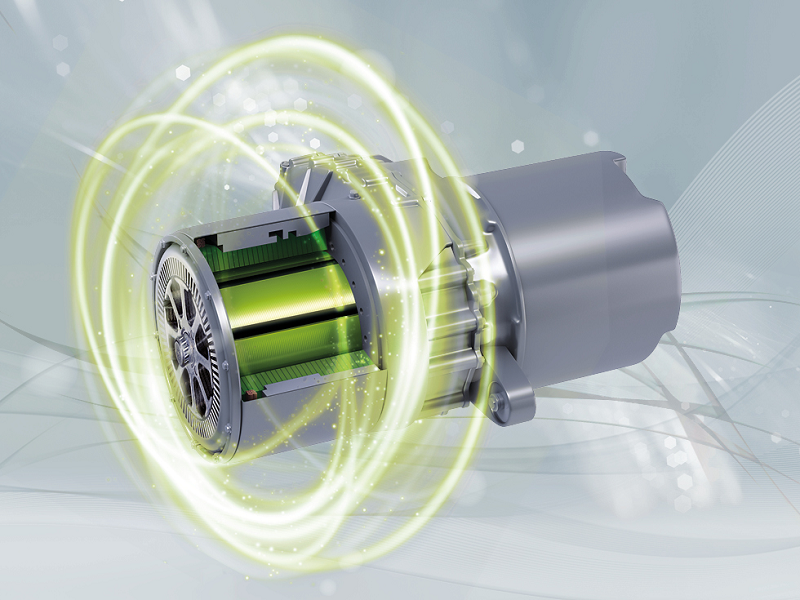

2025-10-24High speed motor iron core material requirements

2023-09-02