Heterostructuring is a strategy that pushes the "banana-shaped" strength-ductility curve of metallic materials towards the upper-right corner, representing a crucial pathway for enhancing the strength and ductility of engineering materials. Designing heterogeneous structures with spatially gradient grain size distributions is an effective strategy for optimizing strength and ductility. Researchers have employed various methods to introduce heterostructures into alloys, primarily including surface mechanical treatment, dynamic plastic deformation, high-pressure torsion, and accumulative roll bonding. However, these conventional methods often require severe or pre-deformation, are typically only suitable for surface gradients, and are difficult to apply to components with complex geometries.

The team at the Institute of Mechanics proposed a method coupling ultrasonic-assisted additive manufacturing. Based on the fundamental principle that ultrasonic-induced "cavitation effects" increase the undercooling at the solid-liquid front, they utilized a self-developed additive manufacturing system coupled with an external ultrasonic field. This enabled active control of microstructural characteristic dimensions, promoted the transition from columnar to equiaxed grains, and refined grain size. By leveraging the characteristics of the hierarchical gradient structure and interface modification, a superior strength-ductility match was achieved. This work was published in the International Journal of Plasticity under the title "Heterogeneous microstructures by combining laser additive manufacturing with auxiliary ultrasound field for strength-ductility betterment."

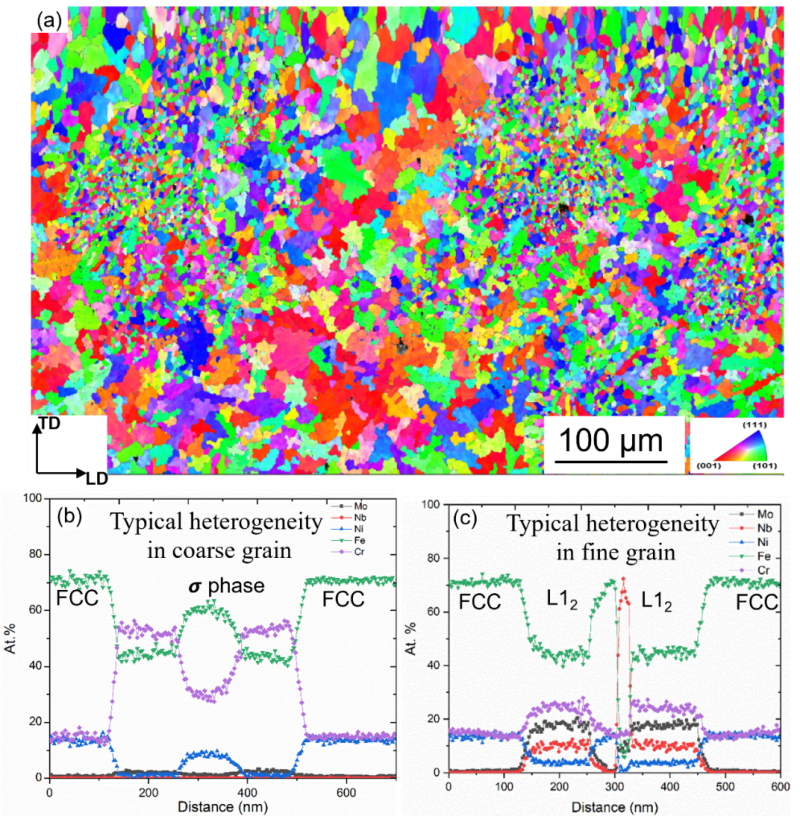

This research successfully fabricated heterogeneous structured 316L stainless steel via coupled ultrasonic additive manufacturing. The alloy exhibits a cross-scale hierarchical microstructure, ranging from millimeter-sized grains, micron-sized cell structures, to Fe-Cr σ phase and L1₂ nano-precipitates distributed at the cell walls, forming a hierarchically gradient microstructure. The study revealed unique cell structure characteristics involving cross-scale and chemical composition perturbations, and clarified the mechanism behind the synergistic effect of multi-stage twinning and metastable cell structures on dislocation slip. The hierarchically heterogeneous 316L stainless steel achieved a tensile strength as high as 1 GPa while maintaining an elongation of approximately 12.5%. This work demonstrates controlled tuning of multi-level heterogeneous microstructures through laser additive manufacturing combined with ultrasonic technology, opening new avenues for microstructure design and manufacturing.

The first author of the study is Assistant Researcher Li Na from the Institute of Mechanics. Researcher Li Yuqiong and Researcher Wei Yujie are the corresponding co-authors. This research was supported by projects including the "Multiscale Problems in Nonlinear Mechanics" project (No. 12588201) and the National Natural Science Foundation of China (No. 12302109).

THE NEW YEAR MESSAGE OF 2021 FROM CHAIRMAN CUHUI,DAI

2021-01-04Guangxi Hongwang Electrical Steel Project Officially Breaks Ground

2024-10-24Zhaoqing Hongwang was Approved to set up Guangdong Doctor Workstation

2020-09-10Hongwang Group's New Project Progress

2022-07-26The first roll of Fujian Hongwang's 400 series products was officially put into the production line.

2023-05-16Hongwang Technology successfully passed the accreditation of CNAS

2022-12-06