With the rapid development of my country's automobile industry, the demand for fuel is increasing, but my country's oil resources are not rich, and fuel vehicles will cause great pollution to the environment. These problems have attracted the attention of the country, and the development of new energy vehicles become an effective way to alleviate the above problems.

At present, the mainstream core material of new energy vehicle motors is cold-rolled non-oriented silicon steel. In the design of the motor, the magnetic properties, processability and economy of the core material should be considered at the same time. Main considerations: low core loss to ensure high efficiency of the motor; high magnetic induction intensity to improve power density and torque density to ensure high motor efficiency. With the continuous increase of the motor speed, reducing the core loss has become the primary task of improving the performance of the motor.

1 Development status of new energy vehicle drive motors

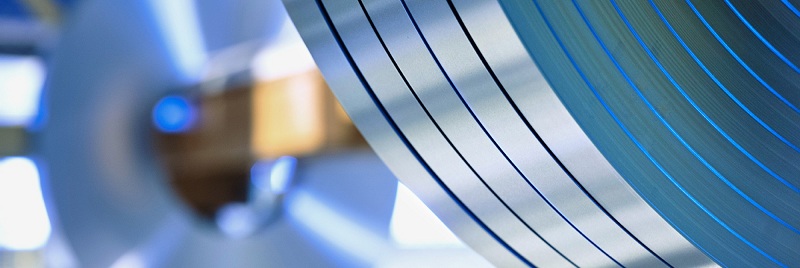

As one of the three core components of the new energy vehicle, the motor's performance index is particularly important. The stator and rotor core of the motor for the new energy vehicle is made of laminated silicon steel sheets with extremely strong magnetic conductivity, which plays a role of magnetic conductivity in the motor. The insulating paint is applied between the silicon steel sheets to insulate the silicon steel sheets from each other and reduce the eddy current loss. In order to improve the efficiency and power density of the motor, the thickness of the silicon steel sheet for the motor has been reduced from the traditional 0.35mm and 0.50mm to 0.25mm and 0.27mm. It is foreseeable that with the increase of motor speed, thinner silicon steel sheets will be gradually applied to new energy vehicle drive motors.

2 Application of silicon steel in automotive motors

2.1 Development Trend of Vehicle Motors

High speed and high power density are the development directions of the drive motor in the future, which requires the drive motor to reduce the size and weight of the motor as much as possible while ensuring the same power. However, reducing the size and weight of the motor will reduce the motor torque. Therefore, it is necessary to increase the motor speed.

2.2 Requirements for new energy vehicles on silicon steel

Cold-rolled non-oriented silicon steel has isotropy in magnetic properties, and is mainly used to manufacture stator and rotor cores of motors. Its isotropy ensures relatively low losses when the motor rotates at high speed.

The iron loss generated in the stator and rotor iron core of the motor is an important part of the motor loss, especially when the motor is running at a high speed, the proportion of iron loss in the total loss increases. According to statistics, the power loss caused by the consumption of silicon steel accounts for 6% of the country's annual power generation , and in the ultra-high frequency state, only the eddy current loss accounts for 40% to 70% of the total loss. This shows the importance of reducing iron loss to improve motor efficiency.

Reducing iron consumption has a great effect on improving the performance of motors and new energy vehicles: first, reducing the temperature rise of the motor to prevent the risk of permanent magnet demagnetization due to excessive internal temperature of the motor; second, improving the utilization rate of electric energy , improve the battery life of new energy vehicles, and effectively promote the rapid development of new energy vehicles.

What is Titanium Grade1 and how does it differ?

2026-01-08Several practical functions of stainless steel screens

2021-04-19Development Status of High end Silicon Steel Market

2025-11-10Application Field of Color Stainless Steel Sheets

2022-05-16What is silicon steel?

2022-09-14Overview of silicon steel market conditions for the first week of January 2024

2024-01-06