Motor Loss Distribution

At present, high-efficiency motors have become the mainstream of the development and application of small and medium-sized motors. Especially industrialized countries such as Europe and the United States are very concerned about energy conservation and environmental protection. Development and application of electric motors. In order to expand the international market share of electric motors, it has become an urgent task for Chinese electric motor manufacturers to adopt new technologies, new processes, and new materials to improve the efficiency of electric motors as much as possible.

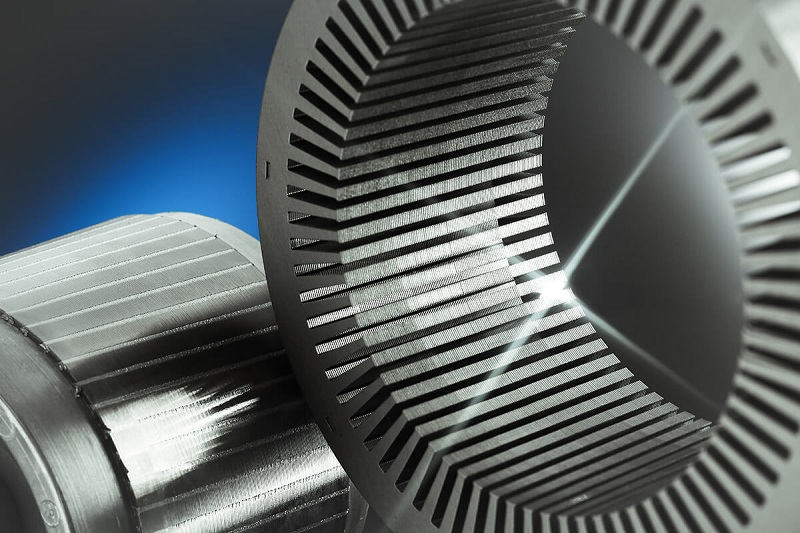

Since the loss distribution of the motor varies with the power and the number of poles, measures should be taken for the relevant losses at different powers and poles. Among them, the selection of magnetically permeable materials is particularly important, which affects the stator copper loss, iron loss and Other properties have a greater impact, and the cost of core materials is the main part of the cost of the motor. Therefore, the selection of silicon steel sheets suitable for high-efficiency motors is the key to the design and manufacture of high-efficiency motors, and should be carefully selected.

Through the comparison and analysis of the electromagnetic properties of silicon steel sheets for motors, the selection and application of silicon steel sheets for high-efficiency motors have been researched and discussed, and through experiments and data analysis, the selection principle of silicon steel sheets for high-efficiency motors has been proposed, which is the core material for high-efficiency motors selection is provided for reference.

Silicon steel sheet introduction

Silicon steel sheet, also known as electrical steel sheet, adding a small amount of silicon to iron can increase the resistivity of the material and significantly improve the magnetic aging, increase the brittleness of the material, and reduce the magnetic induction intensity, so the limit of silicon is 4.5%. Silicon steel sheets are mainly used in power frequency AC electromagnetic devices, such as transformers, motors, transformer switches and relay cores. In my country, silicon steel sheets are traditionally divided into hot-rolled and cold-rolled silicon steel sheets, but in the current world, most of them are divided into non-oriented and grain-oriented silicon steel sheets according to grain orientation.

Hot-rolled silicon steel sheet is magnetic non-oriented silicon steel sheet, which belongs to ferrosilicon alloy. Compared with cold-rolled sheet, it has the characteristics of good material stability, punching shear stress is much lower than that of cold-rolled sheet, small specific gravity, and large difference between the same sheet. The cold-rolled sheet is a low-silicon and low-carbon alloy, which has the characteristics of small iron loss, high magnetic induction, smooth surface, uniform thickness, and small difference between the same sheet. The use of silicon steel sheet instead of carbon steel plate and pure iron in the motor core is a huge progress in history. The low-loss silicon steel sheet improves the performance of the motor and reduces the size of the motor.

Now silicon-free steel sheets are used instead of silicon steel sheets for small motor cores, because the silicon-free steel sheets smelted by modern technology are different from the original low-carbon steel sheets. It not only has high magnetic induction intensity, but also has iron loss similar to silicon steel sheets. Whether it is a cold-rolled silicon steel sheet or a silicon-free steel sheet, its magnetic induction and loss are very sensitive to mechanical stress. Therefore, how to restore its original magnetic permeability and iron loss after punching is a problem that should be considered when choosing silicon steel sheets.

Selection of high-efficiency motor silicon steel sheet

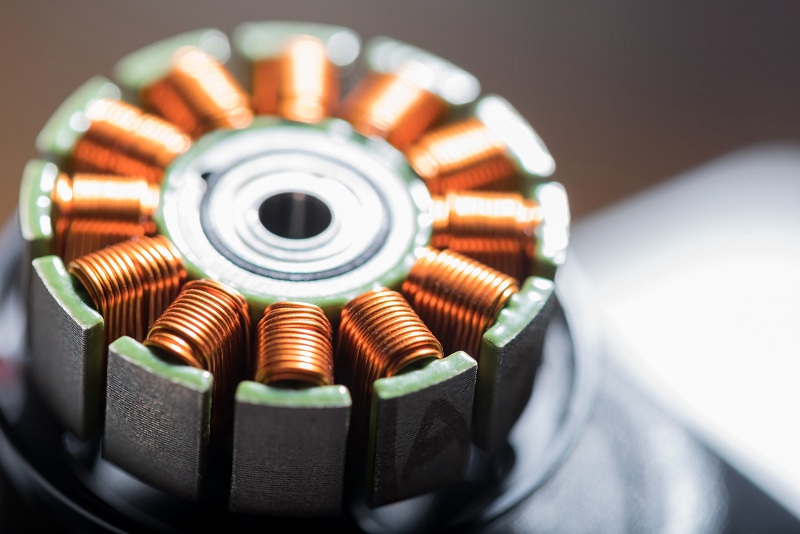

The selection of high-efficiency motor silicon steel sheets should not only pursue high grades and low iron loss, but in fact should be considered comprehensively. Although the higher the grade, the lower the iron loss, the magnetic permeability will be relatively poor, and it is especially important for small motors. . In the 5kW motor, because the reactive current accounts for a large proportion of the stator current, the no-load current (mainly the magnetizing current) accounts for a considerable proportion of the full-load current, reaching about 70%. With the increase of power, the no-load current The proportion of the full load current gradually decreases.

Therefore, for a motor with a small power, the stator copper loss accounts for a large proportion of the total loss, and the electrical steel sheet with good magnetic permeability should be used as the stator core firstly, which can greatly reduce the excitation current and significantly improve the iron loss and the stator core. Copper consumption.

For motors with large power, since the proportion of no-load current to full-load current is small, iron loss already accounts for a considerable proportion of total loss. The use of high-permeability silicon steel sheets is not obvious for improving efficiency, so Reducing the unit loss of the core material will help reduce iron loss.

Due to the design and manufacture of the motor, the iron loss of the motor test greatly exceeds the value calculated according to the unit iron loss value provided by the steel mill. However, after the material is punched and sheared and laminated, it is subjected to a large stress, which deteriorates the magnetic permeability of the punched sheet and increases the iron loss. In addition, due to the existence of the cogging, the harmonic magnetic field of the air gap teeth is on the surface of the core. No-load high-frequency loss is caused, which will lead to a significant increase in iron loss after the motor is produced. Therefore, in addition to selecting magnetic materials with lower unit iron loss, it is necessary to control the lamination pressure and take necessary technological measures to reduce iron loss.

This grade of silicon steel sheet is high in silicon and carbon, low in density, light in weight, good in material stability, basically has no expiration date, and the punching shear stress is much smaller than that of cold rolled sheet. From Table 1, its low-field magnetism is not very good, but it is enough for high-efficiency motors, because the stator flux density of high-efficiency motors is between 1.0T and 1.5T, and the rotor flux density is between 1.0T and 1.0T. 1. Between 6T.

If cold-rolled sheet is used, in order to give full play to its advantages, the mechanical stress after punching and shearing must be solved. There are many theoretical methods to solve the punching and shearing stress of cold-rolled sheet, and the most effective method is to choose a reasonable annealing process. But at present, due to the limitation of equipment and process parameters, this process has not been promoted in China, and this process has only been used in small motors.

According to the theoretical introduction and the test parameters of other motor manufacturers, combined with the export products of home appliances, we also carried out the simulation attempt of this process. Due to the limitation of equipment, we just put the punched silicon steel sheet in the heating furnace and kept it warm at 500°C. 2 hours. The results show that the magnetic permeability of the silicon steel sheet recovers well after annealing, and the iron loss is significantly improved.

Factors that determine the efficiency of high-efficiency motors

The degree of realization of high-efficiency motor efficiency is closely related to the selection of raw materials, especially magnetic materials. High-efficiency motors mainly focus on how to reduce various losses, and how much the design value of iron loss, stator copper loss, rotor copper loss, and stray loss deviates from the test value depends entirely on the selection of silicon steel sheets and the iron core. The quality of manufacture.

What are the design features of modern stainless steel screens?

2022-07-28Iron core soft magnetic material can actually do thermoelectric material?

2024-06-21Surface condition of stainless steel plate

2021-09-09Demand for electrical steel is expected to increase by 3% year-on-year in 2024

2024-04-10Brief classification of silicon steel

2022-09-09New trend of anti-rust packaging of new energy drive motor core

2024-07-29