At present, the main anti-rust packaging method of motor fixed rotor core is anti-rust paper + anti-rust film, and some core surface is coated with anti-rust oil to improve its anti-rust performance. A certain amount of desiccant is generally placed inside the anti-rust package to reduce the risk of corrosion of the iron core caused by high humidity and condensation in the environment.

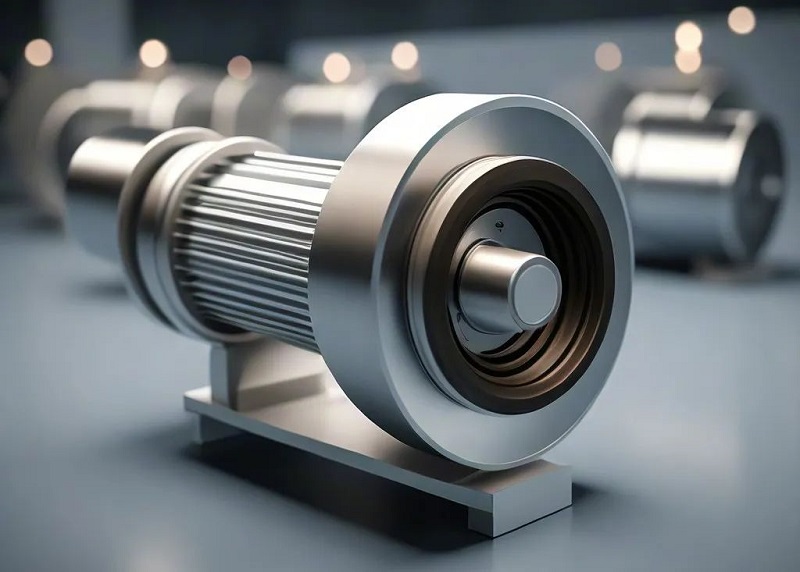

The rotor core is composed of silicon steel sheet superimposed. During storage and transportation, the core coating layer, uncoated layer and processing surface are required to have no discoloration and rust. The traditional anti-rust packaging materials used in silicon steel packaging of new energy automobile motor core are prone to poor adaptability and insufficient anti-rust performance, resulting in discoloration of the coating layer, local rust corrosion of the non-coated layer and the processing surface. The fixed rotor generally adopts a single layer of multiple cores and multi-layer stacking, the internal space is complex and the free space is large, and the non-tightly attached packaging method is insufficient for local rust prevention on the core surface, which is also one of the main reasons for the corrosion of the core surface.

Anti-rust paper is the inner anti-rust packaging material of the rotor core, and the paper fiber directly contacts the core. During storage and transportation, due to friction, collision and extrusion between the core, it is easy to cause paper wool and paper scraps to remain on the surface of the core, making the cleanliness poor. For iron core products coated with anti-rust oil, the strength of the anti-rust paper decreases after oil absorption, which also increases the risk of paper wool and paper scraps remaining on the surface of the steel plate. The low fixed rotor core is generally packaged in a single + whole combination of anti-rust packaging. The single packaging is mostly made of anti-rust paper or anti-rust film bag, and the whole is packaged in anti-rust bag. A whole packaging body is stacked in multiple layers, and each layer is generally placed 12-18 core monomers. Taking the 3-layer core packaging body as an example, if 12 core monomers are placed on each layer, the monomer needs to be repeated 36 times, and the overall packaging is 1 time, and the packaging time generally takes 15-20min. Packaging efficiency is low, labor cost is high, packaging quality consistency is lacking.

In view of the problems existing in the clean anti-rust packaging of the fixed rotor core, the current core production plant generally uses clean new energy silicon steel special anti-rust packaging materials for the overall packaging instead of the traditional monomer + overall combination packaging, with the use of anti-rust, moisture absorption dual function of the rust inhibitor materials, to improve the gas phase anti-rust protection effect, while absorbing the moisture inside the packaging, reducing the risk of core rust. Select the gas phase anticorrosive paper that meets the adaptability requirements of new energy silicon steel to reduce the risk of discoloration of the core surface. The structure of the rust-proof paper adopts a double-layer coating process, compared with the traditional outer single-coated or non-coated rust-proof paper, the rust-proof layer is combined with breathable plastic film, which can ensure the gas phase rust prevention effect and barrier property at the same time, but also fundamentally solve the problem of paper wool and paper dust residual core surface. Select the barrier type anti-rust film material with good adaptability to new energy silicon steel. The base material is made of pure resin polymer material, and the new anti-rust agent is used to improve the barrier property and ensure the gas phase anti-rust protection effect. At present, part of the new energy drive motor core has adopted the overall packaging of anti-rust film instead of the single-layer packaging of anti-rust paper, which has a good application effect and can meet the requirements of end customers.

Traditional drying packaging generally uses desiccant with only moisture absorption function as an auxiliary material, although it can play a role in controlling the internal humidity of the packaging, but it can not enhance the local anti-rust effect of the internal packaging. The rust inhibitor material has the dual function of rust prevention and moisture absorption, which can not only control the humidity inside the package, but also further improve the anti-rust protection effect inside the package and reduce the risk of core surface rust. At present, it has been widely used in cleaning and rust-proof packaging of fixed rotor core with good effect.

Improve the adaptability of anti-rust packaging materials and new energy silicon steel, further improve the cleanliness quality of anti-rust packaging materials, and reduce the risk of discoloration and poor cleanliness of silicon steel surface during storage and transportation. Optimize the fixed rotor core packaging method, improve the packaging efficiency, and further explore the application feasibility of automatic packaging technology in the field of core packaging. The development of new green and environmental protection anti-rust agents for silicon steel, the development of recyclable packaging materials, and further reduce the environmental pollution caused by packaging waste.

Stainless steel surface treatment process, do you like it?

2022-10-15The future development trend of motor

2022-11-07Difference between medical stainless steel and food grade stainless steel

2024-04-29What is duplex stainless steel and why so many person are concerned of S32001 duplex ?

2022-07-18The influence of the production technology of motor punching on the quality iron core

2023-08-31The artistic beauty of stainless steel corrugated board

2021-06-10