The cores of transformers can generally be divided into the following two categories:

(1) Shell core. This core is generally rectangular in cross-section, with 2 side yokes per core column, and is called shell type as the core is enclosed outside the winding as if it were a shell. Shell cores have fewer chip specifications, the core is easily fastened and the side yokes help to reduce the additional losses caused by leakage flux. Shell cores are also divided into single-phase and three-phase, and the three-phase shell type can be seen as consisting of three separate single-phase shell transformers placed side by side.

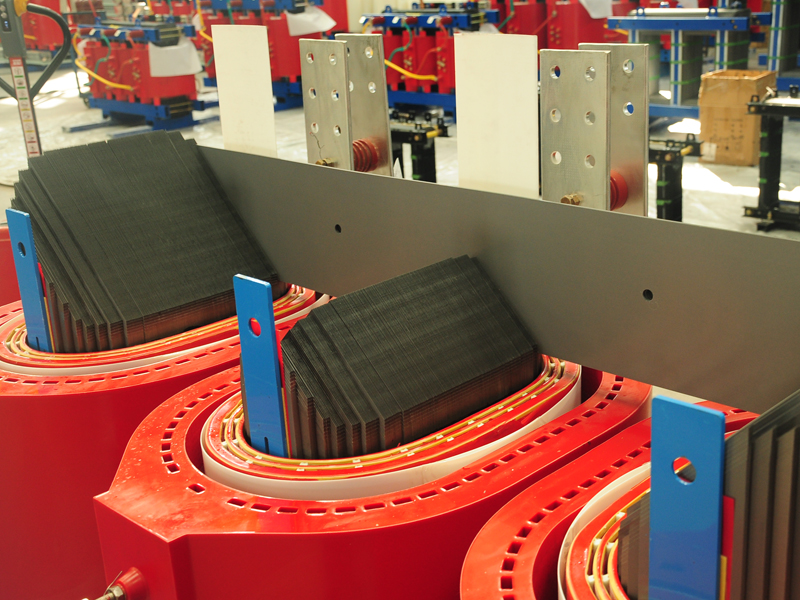

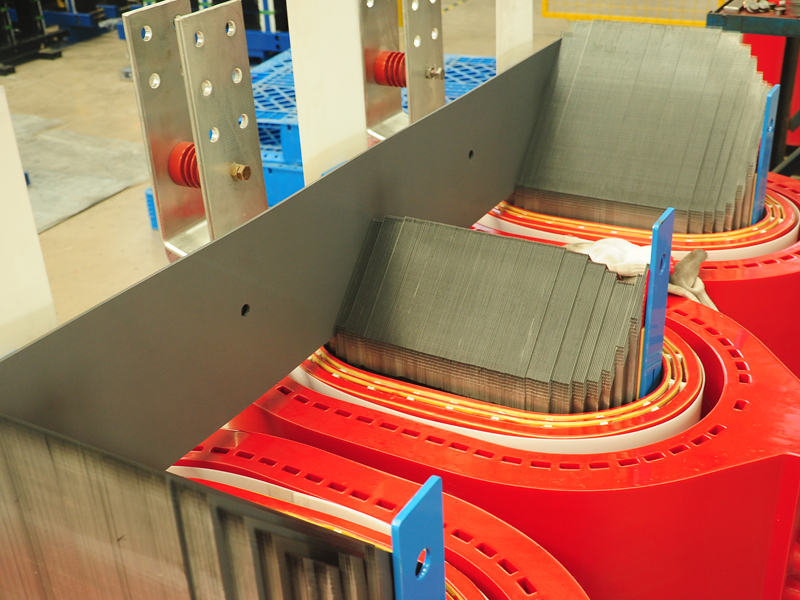

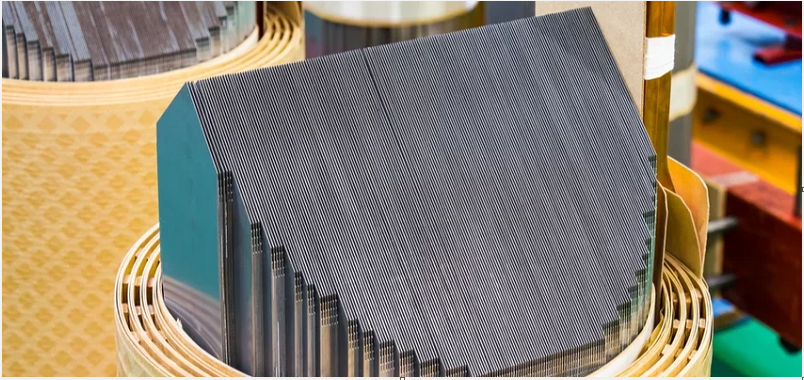

(2) Core-type iron core. This kind of core has a graded cylindrical cross section and the winding surrounds the core, so it is called core type, also known as inner iron type. This kind of core has more chip specifications, tying, and clamping requirements, but the winding is cylindrical, has convenient winding, good short-circuit stability, and the insulation between the winding and the core is also easy to handle, so it is widely used. At present, the transformers produced in China generally use core-type iron cores.

The transformer is manufactured according to the principle of electromagnetic induction. The core is the magnetic circuit of the transformer, which is made of silicon steel sheets with good magnetic conductivity processed and stacked so that the magnetic flux can easily pass through the core for electromagnetic induction. The main role of the core is to act as a medium for the conversion of electrical energy, through which the output voltage of the transformer can be raised or lowered in conjunction with the number of turns of the winding. At the same time, the core is also the skeleton of the transformer, which sets the windings and supports the leads, wooden clamping elements, tap changer and some other components.

Stainless Steel Water Pipe Market Scale Reveals: Unlimited Potential Investment Opportunities

2025-10-27High grade eletrical steel material or usher in structural prosperity

2023-09-07Where is the application field of 316L stainless steel pipe drawing technology?

2021-03-10NEW RECORD! 2019 Global SS Slab Production Reached 52.4 Million MT!

2020-11-03A 60000 Ton Bridge Supported by Hegang

2020-12-15Applications of the highest class of non-heat-resistant refined domain oriented electrical steels

2023-11-30