Stainless steel can be divided into 200 series, 300 series and 400 series three categories, of which 300 series is the most commonly used, 200 series and 400 series is a certain way of 300 series of substitutes, and strictly speaking, 400 series is not called stainless steel, called stainless iron, because it does not contain nickel elements, so magnets can be attracted. The 200 series and 300 series have nickel, so they are not magnetic and cannot absorb iron. 304 is the most common variety in the 300 series, so the price change of 304 can generally determine the price trend of the entire stainless steel. The 200 series contains less nickel, the 400 series does not contain nickel, and the 300 series contains the most nickel, so the 300 series is the most affected by the nickel price. 300 series can be simply divided into 304, 304L, 316, 316L, 321, 309S, 310S, etc., the distinction is based on the different content of various metal elements, the characteristics of stainless steel with different content are not the same, the difference between 304 and 304L is the difference in carbon (C) content, with L is said to contain low carbon, also called low carbon, The difference between 316 and 316L is the same.

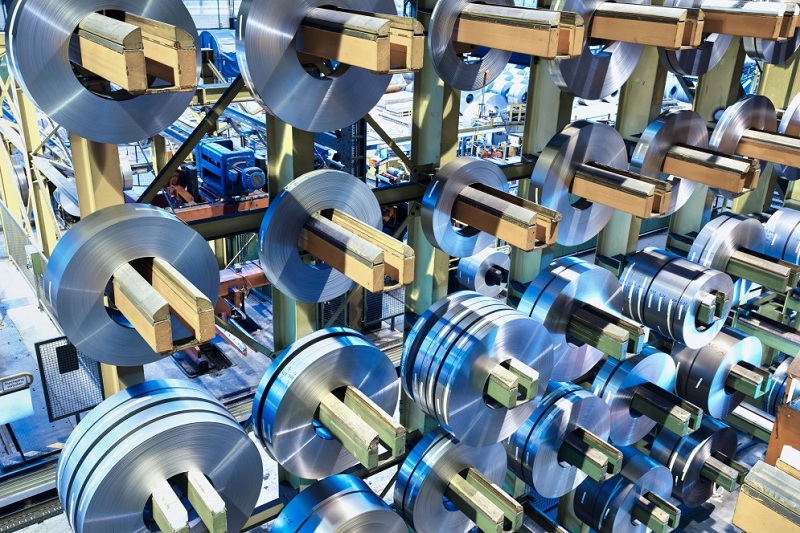

Stainless steel can be divided into five categories: iron coil, iron plate, profile, steel pipe and parts, and the most important is iron coil and iron plate. Profiles are all kinds of materials made of different shapes of plates, including Angle steel, flat steel, I-steel and channel steel. Steel pipe mainly refers to seamless steel pipe, and the opposite of seamless steel pipe is welded pipe, the difference is whether it is formed at a time. Parts mainly refer to elbows and flanges and other small things. The coil and the plate are actually the same, the factory form is not the same, the iron coil is a roll, the iron plate is a sheet, if the factory is the plate, also known as the original plate, generally thick plate, because it is very thick, it can not be rolled, generally more than 16 mm can not be rolled. There is a volume, there is a board, many times is the board, the price of the volume and the board is not the same, if it is the purchase volume, it is calculated according to the actual weighing, so the price is high, the board is calculated according to the theory, the price is low, the reason is that there is a lower difference, such as the actual 10mm thick may be 9.6mm, there will be a price difference in the middle.

Stainless steel plate according to the rolling mill (rolling mill is the machine name of the rolled plate) rolling process is different, divided into hot rolling and cold rolling, hot rolling is usually marked as NO.1 cold rolling mark 2B or BA(BA than 2B surface good, bright, close to the mirror, the best is the mirror, the mirror is not in stock, all need to process), such as 304 many times is the purchase board, That means the roll has to be flattened into a plate by a machine, and that machine is a flattening machine. Domestic cold rolling is generally below 3 mm, hot rolling is generally above 3 mm, and the thickness of 3 mm is both hot rolling and cold rolling, but the thickness of the imported cold rolled sheet can reach 4 mm or even 6 mm. Hot rolled 3 mm to 12 mm plate is called the plate, 12 mm or more is called the thick plate, can be thick to 120 mm or more, and called the hot rolled plate, and cold rolled is cold rolled sheet.

304, as a widely used steel, has good corrosion resistance, heat resistance, low temperature strength and mechanical properties, stamping, bending and other hot processing properties, no heat treatment hardening phenomenon, non-magnetic, the use of temperature from minus 193 degrees to positive 800 degrees. Uses: tableware, kitchenware, water heater, boiler, auto parts, medical equipment, food machinery, wine storage, pressure vessel. 304L as a low-carbon 304 steel, in the general state, corrosion resistance and 304 is about the same, but after welding and stress relief, it has good resistance to intercrystalline corrosion, in the case of no heat treatment, it can also maintain good corrosion resistance, generally used at 400 degrees, use: petrochemical industry, building materials. 316 Low carbon added MO element, so his corrosion resistance and atmospheric corrosion resistance and high temperature strength performance is particularly good, can be used under harsh conditions, suitable for use below 900 degrees, non-magnetic. Uses: Equipment used in seawater, chemical, dye, paper, acetic acid, fertilizer and other production equipment, food industry and coastal facilities, products with special requirements against intercrystalline corrosion.

The 200 series is similar to the 304 and is cheap and economical. Uses are food processing utensils, kitchen equipment, food processing equipment, filters, milk cans, consumer durables, washing machine accessories, water heaters, steel furniture, architectural decoration, decoration. In terms of fatigue resistance, 201 hardness is larger, toughness is not as good as 304, or 304 fatigue resistance is better.

Why is the motor "iron" core?

2023-09-14Why does stainless steel also rust?

2020-12-18The Future Development of Stainless Steel Water Pipes: Optimistic or a Bubble?

2026-01-06Influence of stator lamination on motor noise

2023-12-26Breaking Through the Bottleneck of High-Frequency Power Equipment: Amorphous/Nanocrystalline Core Technology Ushers in a New Era for Solid-State Transformers

2025-12-01Properties and applications of electrical steel stainless steel tubes

2023-11-25