We can also think of an iron core as an "amplifier" of a magnetic field: if the surrounding medium is a vacuum, a current (assuming DC) can only generate a minimal magnetic field around it, and the strength of this magnetic field is proportional to the size of the current, but if the surrounding medium is a magnetic material, the "original" magnetic field induced by the current will be amplified. Therefore, from the perspective of permeability, stainless steel is of course the preferred material.

In the usual work process, about the iron core, the most common word we hear is "electrical steel sheet". In order to increase the permeability of the stainless steel punch, we will add a small amount of "silicon". With the increase of electrical steel, the hysteretic coefficient of electrical steel decreases, the iron loss decreases, and the permeability increases. When the electrical steel reaches 6.5%, the magnetic permeability of the electrical steel reaches the maximum value and the magnetostriction approaches zero, which has excellent magnetic properties. However, when the electrical steel exceeds 3.5%, the steel will become hard and brittle, which cannot be rolled into thin steel plates, which is one of the reasons why it is difficult to make thin electrical steel sheets. In addition to silicon, cobalt can also be added, the so-called cobalt steel sheet.

The motor iron loss includes the basic iron core caused by the change of the main magnetic field in the core, the additional (or stray) loss in the core when there is no load, and the loss caused by the leakage field and harmonic magnetic field caused by the stator or rotor operating current in the iron core. The latter two items are generally classified as stray costs, which are difficult to quantify accurately. Basic iron core loss includes core hysteresis loss and eddy current loss. Hysteresis loss is the energy consumed by ferromagnets due to hysteresis in the process of repeated magnetization. The hysteresis loss per unit volume of the iron core per cycle is proportional to the area of the hysteresis loop. This part of the energy is converted into heat, which heats up the equipment and reduces efficiency.

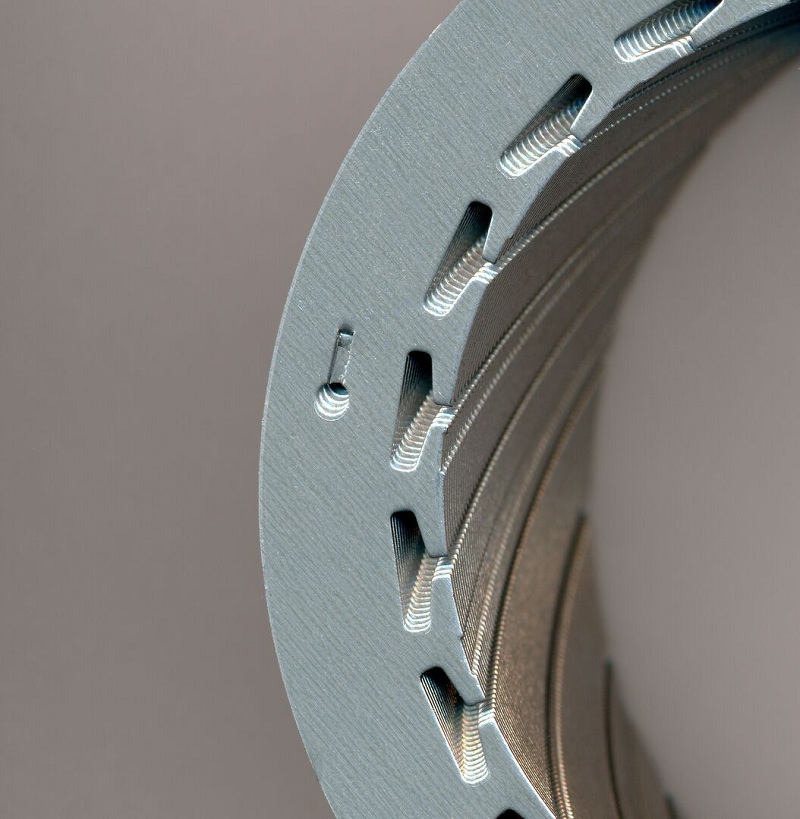

When a conductor moves in a non-uniform magnetic field or is in a magnetic field that changes with time, the energy loss caused by the induced current in the conductor is called eddy current loss. Due to the existence of eddy current losses, in order to reduce eddy current losses, the iron core is often stacked with many sheets, which are coated with a thin layer of insulating paint or insulating oxide. When the magnetic flux passes through the narrow cross-section of the wafer, the eddy current is limited to a few narrow loops in each wafer, reducing the series of loops. It is called "breaking the whole into pieces".

The magnetic flux generated by the magnetic pole of the permanent magnet synchronous motor is divided into two parts: one part is cross-linked with the armature winding through the air gap, called the main magnetic flux (effective magnetic flux), and the other part is not cross-linked with the armature winding, called the leakage magnetic flux (invalid magnetic flux). The ratio of the total magnetic flux to the main magnetic flux is called the leakage magnetic coefficient. In the permanent magnet motor, in order not to make the permanent magnet leakage coefficient is too large and lead to the utilization rate of the permanent magnet is too low, the magnetic insulation measures are taken: the silicon steel sheet is separated between the two permanent magnets, and the silicon steel sheet between the two permanent magnets is called the magnetic insulation bridge. The word magnetic bridge is actually very misleading, and it is very unfriendly to motor beginners. In fact, what really works is the Flux Barrier, and the magnetic slot of the rotor is not 100% filled with magnetic steel, but leaves a part of the air gap. The air gap is full of air, the permeability is low, the magnetic resistance is large, it can guide the magnetic density line through the narrow fixed rotor air gap, decoupling the stator winding, forming an effective magnetic flux, rather than directly through the rotor core to form a magnetic field closure, forming a waste of magnetic leakage.

By setting barriers, let the magnetic sensing line go where it should go, which is the purpose of the magnetic bridge, in fact, called "guide bridge" more easy to understand. The smaller the thickness of the magnetic separation bridge, the easier it is to form magnetic saturation, and the more magnetic dense lines can be guided to form effective magnetic flux, and the smaller the magnetic leakage. In the actual design process, it is necessary to consider the mechanical strength of the film. With the development of high-speed motor, the test of magnetic bridge is huge. That's why the Tesla Model S uses carbon fiber rotors.

What Role do Laminations Play in Electric Motors and Generators?

2023-01-31321 and 304 stainless steel corrosion resistance and high temperature performance

2024-07-06Tips on 304 stainless steel pipe cleaning and maintenance

2020-12-21Comparison of cold rolled steel sheet and hot rolled steel sheet

2021-09-13Demand for electrical steel for UHV power grid projects

2024-02-21Is the iron core material of the motor as thin as possible?

2024-01-05