Last December, at the picturesque Taboux airfield in southwestern France, a milestone moment for electric hybrid aircraft was officially reached with the first test flight of a demonstration aircraft. The EcoPulse demonstrator, jointly developed by Airbus Group, Daher Group and Safran Group, kicked off an eight-month test flight cycle to explore and establish the feasibility of a distributed hybrid propulsion system.

The hybrid propulsion system is part of the Airbus Group's decarbonisation roadmap, but Airbus Group is not alone in its efforts to become more environmentally friendly in the aviation industry. Hybrids are key to the transformation of the aviation industry, with studies showing that they can reduce the environmental impact of aircraft by up to 5%. The maiden flight of the EcoPulse demonstrator therefore represents an important milestone in the electrification of the aviation industry.

This arrangement of the propulsion system and the corresponding wing flow improves the aerodynamic and structural performance of the aircraft, which, combined with the more efficient steel electric engine, increases the marginal gain. Conventional propulsion engines are used for takeoff and landing, while hybrid propulsion systems are deployed after the aircraft reaches cruising altitude. Because hybrid pods complement rather than replace existing engine systems, they must be as lightweight and efficient as possible, and material selection is key.

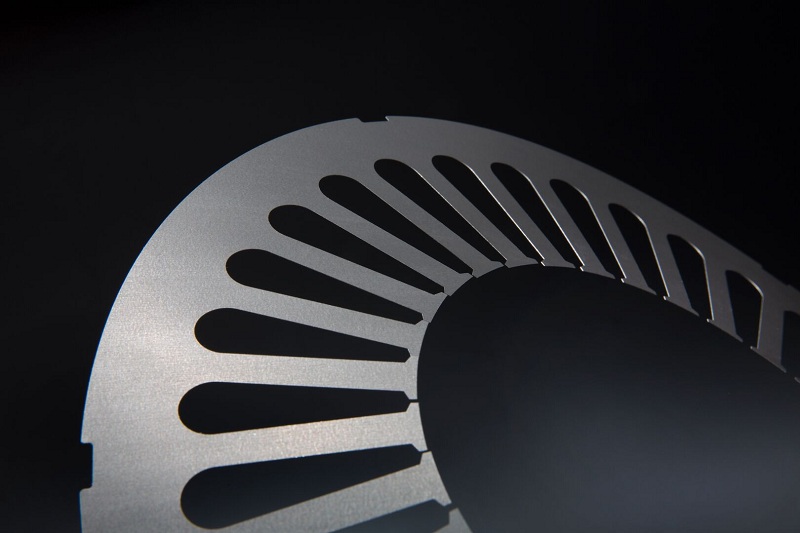

Electrical steel is magnetic and essential to the operation of motor stators and rotors. Electrical steel can withstand the mechanical pressure generated by the high speed of the motor, helping to minimize core energy loss. Continuously improving engine efficiency to keep energy losses to a minimum is essential for the future of aviation. Therefore, in order to meet this special demand, aviation companies are developing new high-tech electrical steel. With the introduction of lighter, more efficient electric engines, those aircraft using sustainable propulsion systems will further increase their range.

By testing state-of-the-art lightweight batteries and electric engine systems, we will gain valuable data on the future application of hybrid propulsion systems in the aviation industry." Learning from the lessons learned on the demonstration aircraft and evaluating how the technology can be applied to various aircraft types, such as large airliners, is a critical stage in greening the aviation industry. As steel electric flight technology continues to mature, it has the potential to make air travel a more sustainable mode of transportation and help keep the world connected.

Research Progress in Hierarchically Heterogeneous 316L Stainless Steel by Additive Manufacturing at Institute of Mechanics

2025-10-24Strengthen Industry Self-Discipline, Improve Quality and Efficiency, Guide the Stainless Steel Industry Towards Sustained and Healthy Development

2025-12-11Market analysis of global stainless steel industry in 2023

2023-10-21Modern Die Technology of Motor Stator and Rotor Iron Core

2023-03-15The role of stainless steel in offshore applications

2024-04-18Application of Oriented Silicon Steel Sheets in Transformers

2025-10-14