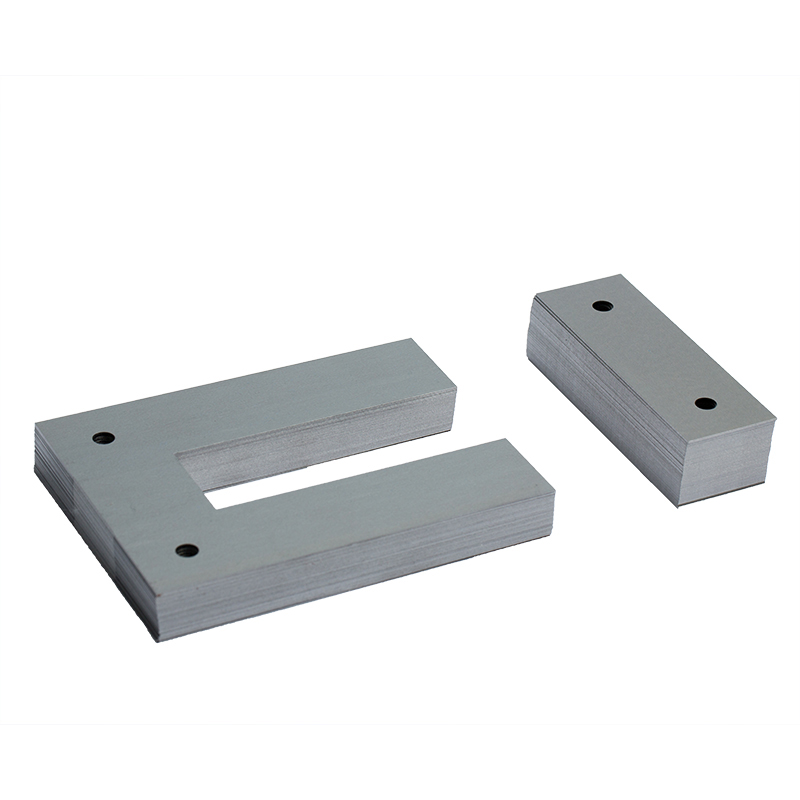

The main body of a transformer consists of a core and conductors. The core is primarily made of laminated silicon steel sheets. Silicon steel sheets are steel plates with a silicon content of 0.8% to 4.8%, exhibiting strong magnetic conductivity. In transformers, silicon steel sheets can generate high magnetic flux density, and their performance directly influences the transformer's size. Iron loss is the most critical metric for silicon steel sheets—generally, lower iron loss corresponds to higher grades and better quality. Additionally, flatness is another key indicator for silicon steel sheets. Sheets with superior flatness exhibit higher stacking coefficients, better coating adhesion, and improved weldability.

Beyond silicon steel sheets, other core materials for transformer manufacturing include electromagnetic wires, insulating materials, and transformer oil. However, silicon steel sheets account for 30-40% of the production cost of transformers.

Transformers are classified by capacity into large transformers (with a capacity of 8,000 KVA or more) and small to medium-sized transformers (with a capacity of 6,300 KVA or less).

By voltage level, they are classified as 6KV, 10KV, 35KV, 60KV, 110KV, 220KV, 330KV, 500KV, 800KV, and 1000KV; the third category is based on transformer usage, including step-up transformers, step-down transformers, distribution transformers, and power plant transformers.

According to the transformer winding configuration, there are double-winding, triple-winding, multi-winding transformers, and autotransformers.

Transformers are classified by cooling conditions into types such as oil-immersed self-cooling, dry air self-cooling, oil-immersed air-cooled, oil-immersed water-cooled, dry resin-cast insulation, forced oil circulation air-cooled, and forced oil circulation water-cooled.

In addition, there are special transformers, rectifier transformers, furnace transformers, test transformers, mining transformers, shipboard transformers, traction transformers, medium-frequency transformers, and high-current transformers.

Silicon steel sheets are the main material used to construct transformer cores. The basic requirements for transformer cores are low core loss at a certain frequency and magnetic flux density, and high magnetic flux density at a certain magnetic field strength. Small unit iron loss is the most important indicator of silicon steel sheets. Countries around the world classify silicon steel sheet grades based on iron loss values. The lower the iron loss, the higher the grade, and the better the quality. A smaller excitation current per unit magnetization capacity can obtain a larger magnetic induction intensity. A higher saturation magnetic induction intensity can obtain silicon steel sheets with higher magnetic induction intensity under the same magnetic field strength. The required volume and weight for manufacturing products are relatively small, which can save silicon steel sheets, copper wires, and insulation materials; Silicon steel sheets with good flatness have a smooth and even surface, uniform thickness, high stacking coefficient, good punching performance, tight adhesion between the coating and the bottom layer, and good adhesion to prevent coating detachment during processing. The surface of the silicon steel sheet has good adhesion and weldability to the insulation paint film, and the growth rate of coercivity or iron loss that changes with the use time of magnetic aging is small. The silicon steel sheet must be annealed and pickled before delivery.

Silicon steel sheet and iron loss: Transformer iron loss refers to the no-load loss of the transformer. The no-load performance of a transformer mainly refers to the no-load loss and no-load current during the operation of the transformer. When a transformer is put into operation on the power grid, no matter how much load it carries, there will always be no-load losses. To reduce the energy consumption of power grid operation, the main focus is on reducing transformer no-load losses. The magnitude of no-load loss in transformers is mainly determined by the material of silicon steel sheets, as well as the design and manufacturing process of the iron core.

Silicon steel sheet and stacking coefficient: The stacking coefficient is an important indicator reflecting the manufacturing level of transformers, closely related to the material quality of silicon steel sheets. The influencing factors mainly include: silicon steel sheet thickness, same plate difference, surface thickness tolerance and flatness, insulation layer thickness and insulation layer thickness tolerance, as well as burrs, waviness, flatness, etc. during punching and shearing processes.

Hongwang Group was honored to rank 435TH in "TOP 500 CHINESE ENTERPRISES"

2022-09-07Hongwang Hi-tech | Intelligent Production of Single Continuous Rose Gold

2021-05-14HWHG successfully signed the HuiShan project

2023-12-08Yield Strength Vs Tensile Strength

2023-06-26China Terminates AD review on GCNS’s stainless steel billet & HRC

2021-11-232020 HONGWANG FINAL NEW SURPRISE,THEY ARE COMING!

2021-01-07