Water jet cutting

Water jet cutting is the use of nozzles to generate high-pressure water jets carrying fine abrasive particles for cutting. This method is very effective for cutting gold and non-metallic materials. The process uses high capacity pumps and the water and electricity requirements are very high. This method can cut thick-gauge stainless steel (>100mm) without generating a heat-affected zone (HAZ) or changing the metallurgical structure of the stainless steel sheets. Although the water jet cutting quality is good, but when the cut section is thicker, the bevel angle of the cut surface is larger. It is not economical to cut thin steel plates with this method, but stacking multiple thin steel plates can cut multiple stainless steel sheets at a time.

Plasma cutting

Plasma cutting is the most commonly used method for cutting all grades of austenitic stainless steel plates with a thickness of 25mm and above. The design of the plasma gun significantly improves the accuracy and cutting quality, and is an ideal process for cutting straight lines or special shapes. In some cases, the cut quality of plasma cutting is so good that it can be used directly or as a welded joint without further processing. Since plasma cutting does involve high temperatures and localized melting of the metal, the corrosion resistance of the incision is reduced, and portable plasma cutters can cut shaped stainless steel sheets or specimens. Underwater plasma cutting reduces fume.

In plasma cutting, the stainless steel grade and cutting thickness are important factors that must be considered when selecting plasma gas. Avoid the use of oxygen-containing gases, as oxygen will cause the formation of a chromium oxide layer on the surface, thereby depleting the chromium below the surface and reducing corrosion resistance. Slight discoloration of the cut surface, indicating chromium oxidation. If severe discoloration occurs, subsequent pickling or edging will be required to restore corrosion resistance. Nitrogen assist gas must be certified to be at least 99.95% pure with a maximum oxygen content of 200ppm. In addition to N2, other gases commonly used in plasma cutting of stainless steel are mixed gases of N2 and H2 or Ar and H2.

Variables such as gas flow rate, arc current, nozzle design, and cutting speed all affect the width, shape, and quality of the cut. For different grades and thicknesses of stainless steel, the plasma cutting equipment manufacturer should be consulted for specific recommendations.

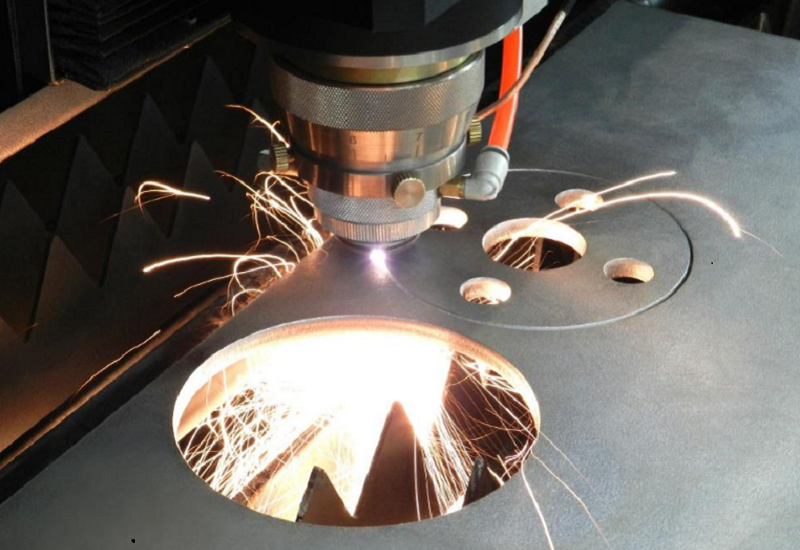

Laser cutting

In laser cutting, a laser beam melts the material while a nitrogen jet blows the melt away from the cut. Nitrogen prevents oxidation and loss of corrosion resistance. When laser cutting stainless steel, the nitrogen pressure is greater than the oxygen pressure when cutting carbon steel. In order to effectively blow away the molten metal, the nitrogen pressure needs to increase as the thickness of the material increases. Compared to plasma cutting, laser cutting is faster, has narrower kerf widths and higher quality cuts, and can usually be used without further processing of the cut. Compared with plasma cutting, the disadvantage of laser cutting is that the cutting thickness is limited. Current laser cutting equipment can only cut stainless steel with a maximum thickness of no more than 12 mm. Laser cutting machines cut high performance austenitic and standard austenitic stainless steels to final size without the need for additional machining. There is little difference in the laser cutting properties of high performance and standard austenitic stainless steels.

Selection of silicon steel sheets for high-efficiency motors

2023-02-25Key points of special-shaped bending of stainless steel plate

2021-08-19Cold rolling stainless steel and hot rolling stainless steel

2021-01-05What are the design features of modern stainless steel screens?

2022-07-28The mysteries of stainless steel: Types, properties and applications

2024-06-22Unveiling the "Zinc" Armor: How Hot-Dip Galvanized Materials Safeguard Modern Industry

2025-12-19