Stainless steels (SSs) are the most widely applied alloys in engineering and daily life, which are divided into five different grades including austenitic, ferritic, duplex, martensitic and precipitation hardening stainless steels. Austenitic stainless steel SS316 (Fe-Cr-Ni) is utilized for automotive applications and construction due to its good ductility and exceptional resistance to corrosion . However, its drawbacks include low hardness and poor wear resistance. On the other hand, martensitic stainless steel SS420, with a high carbon content, is extensively utilized in aerospace and automotive industries for its high hardness and strength . However, its limited plasticity and moderate corrosion resistance are the shortcomings for practical applications. Additionally, duplex stainless steels such as 2205, with the equal proportion of the austenite and ferrite, exhibit superior mechanical and corrosion properties and high stress corrosion cracking resistance . Although duplex stainless steels possess better overall performance, the economic perspective is also a big obstacle. The precise control of alloy compositions and the higher amount of chromium result in a higher production cost compared to single-phase stainless steels, such as SS316.

Based on the excellent corrosion performance of austenitic stainless steels and the mechanical strength of martensitic stainless steels, duplex stainless steel offers superior performance in both areas. Considering cost-effectiveness, composite materials that combine these two types of stainless steels are proposed. A composite is an innovative material that features a microstructure providing advanced capabilities, which are challenging to achieve with conventional alloys . These changes could be triggered by heterogeneity in the grain structure, phases, and compositions. The synergistic effect resulting from the interaction and coupling of heterogeneous zones enhances the mechanical properties of the material . Previous research has indicated various techniques for fabricating the composites with hetero-structures, as listed in Table 1. Surface mechanical attrition treatment was an effective method for fabricating a nitriding steel-based heterostructure with gradient layers consisting of nano-sized and deformed grains, achieving hardness levels of up to 1340 HV . The 13Cr-5Ni-2Mo with 8 wt% Mn was produced using the hot forging method and post cold rolled to obtain a hetero-structure structure of coarse and fine grains, which exhibited high yield strength (YS, 923 MPa) and high tensile strength (TS, 1085 MPa) . Additionally, the laser melting deposition was used to fabricate hetero-structure steel with different powder ratios of 18Ni300 and SS316, resulting in a better strength-ductility combination with ultimate tensile strength (UTS) of 1678 MPa and high percent elongation (%EL) of 11 % . The structure formed with different ratios of SS420 and Inconel 718 in powder form was fabricated by laser directed energy deposition and the TS and %EL were between those of SS420 and Inconel 718, indicating that the fabricated structures were balanced in between both alloys . Moreover, different techniques including wire and arc additive manufacturing , hot isostatic pressing , selective laser melting and friction surfacing (FS) were used to fabricate the structure with two or more materials for forming hetero-structure or multi-material structure. However, the aforementioned methods involve complex operating procedures, high production costs, low efficiency, and a limited size range of prepared components, making it difficult to create high-performance bulk and large-sized coatings and structures, which could significantly limit practical applications. Additionally, most of the research has focused primarily on mechanical properties, while corrosion properties have not been addressed.

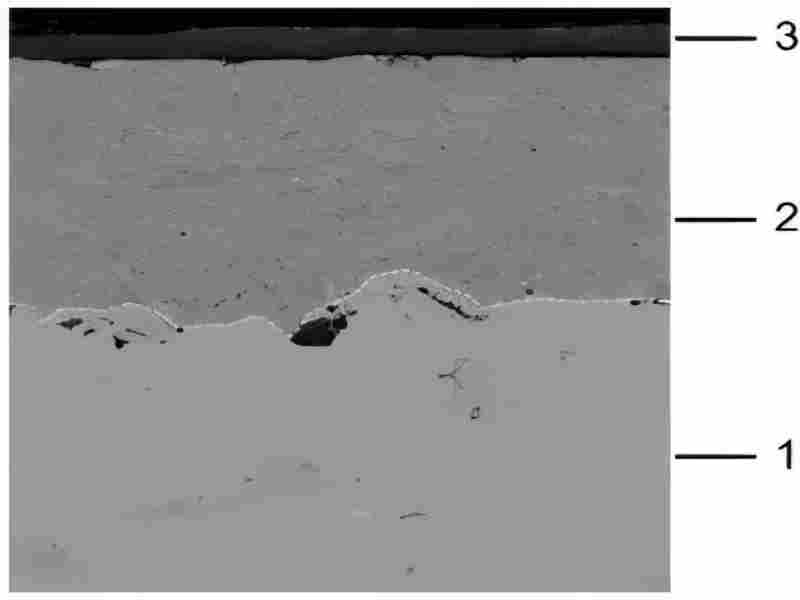

For solving the above problem, FS was selected to fabricate the composite coating aiming at achieving superior properties. In the present work, both the utilized consumable and filler materials are in the form of rods. FS involves the rotational consumable rod pressing against the substrate where frictional heat was generated and the rod was softened. The softened rod undergoes plastic deformation, allowing the material to deposit below the melting temperature . Compared to other fabrication techniques, FSed coatings can be produced in an environmentally friendly way and are characterized by the absence of defects, pores, and dilution . In the literature, the improved mechanical and corrosion properties have been highlighted using FS. The friction-surfaced (FSed) 316 coating has shown enhancement in the pitting corrosion resistance due to the absence of δ-ferrite and the fragmentation of MnS inclusion . The pitting corrosion resistance increased and hardness up to 722 HV0.3 was obtained in the SS420 after friction stir processing (FSP) . Based on the aforementioned advantages of FS, the consumable rod made from combining SS316 and SS420 is attempted, with the aid of plastic flow mixing during FS and the benefit of solid-state processing, i.e. below the melting point, the grains are refined and the alloying elements diffusion zone is controllable, hence forming a unique hetero-structure coating and further investigations were done on its properties. Compared to other coating techniques, such as laser-based cladding processes, FS is regarded as a reliable and cost-effective method, featuring an intermediate deposition rate and significant application value in engineering . Through the optimization of the processing parameters, the joining and coating efficiency can reach up to 75 % and 50 % respectively while simultaneously minimizing the unbonded region to 8 %.

Previous studies on heterostructure materials have primarily concentrated on fabrication techniques that involve incorporating elements or alloys in powder form. In this work, the concept of fabricating the metallic composite coating via FS was proposed with the utilization of a hybrid consumable rod, which is made of SS316 and SS420, prepared by embedding a thin SS420 filler rod into a thicker SS316 consumable rod that has been pre-drilled. Both the consumable rod and filler rod provide a distinct configuration compared to powder-based methods. This allows for the formation of a composite coating through material flow during FS. Moreover, most prior research was focused solely on the enhancement of mechanical properties, often neglecting corrosion resistance. This oversight is primarily due to the challenge in balancing corrosion resistance with mechanical performance. The present study emphasizes the importance of corrosion resistance, which is as critical as mechanical properties for applications in marine environments. Therefore, a comprehensive study is conducted to characterize the microstructure, hardness, mechanical properties, as well as the wear and corrosion resistance of the composite coating. The proposed method in this work offers a new and efficient way for fabricating the low-cost functional multi-phase coatings which have the potential to provide valuable insights on the preparation of hetero-structure coatings with superior performance, which is also of great significance for industrial applications.