Continuously Evolving Hongwang Titanium

Titanium, hailed as the "Space Metal" and "Marine Metal," occupies an irreplaceable position in high-end manufacturing.

However, the complexity of titanium processing techniques and technological barriers have long been key challenges constraining industry development.

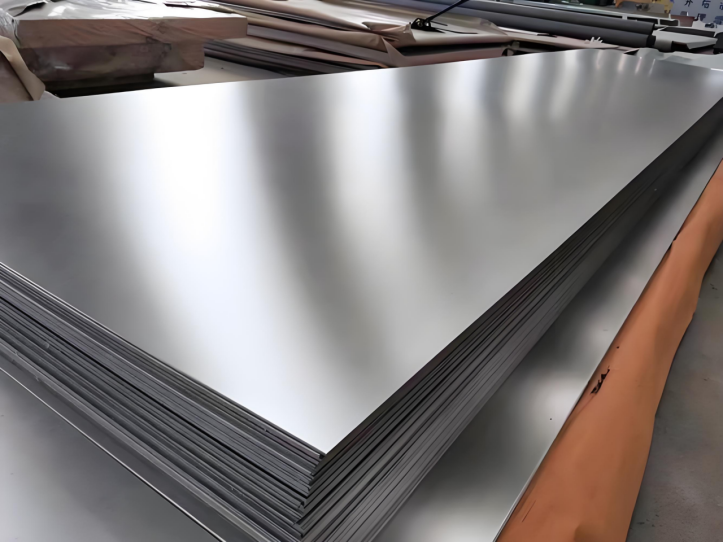

Hongwang Titanium, driven by independent innovation, delves deep into core cold-rolling titanium technology, breaking through process bottlenecks. We provide high-end manufacturing with titanium materials characterized by "High-Precision, High-Performance, and High-Stability."

"Millimeter-Level Control" with 20-High Rolling Mills

Hongwang Titanium utilizes internationally leading 20-high precision rolling mills. Through high-rigidity roll systems and intelligent closed-loop control, we achieve precise thickness tolerance control, far exceeding Chinese (GB) and American (ASTM) standards. The finished product thickness range covers 0.3-2.0mm, meeting the needs of ultra-thin components for consumer electronics and aerospace applications.

Intelligent and Precise Regulation of Shape Control System

Closed-Loop Shape Control System:

Integrates real-time shape roller monitoring, intermediate roll shifting adjustment, and backup roll crown compensation technology to eliminate defects like wavy edges and warping.

Combined Leveling + Tension Leveling Technology:

Optimizes sheet flatness for different application scenarios (e.g., smartphone hinges, chemical equipment), ensuring zero errors in subsequent processing.

"Full-Process Control" from Composition to Process

Customized Composition:

Precisely designs titanium alloy composition ratios based on end-use requirements (e.g., antibacterial properties for medical devices, high-strength lightweight for aerospace structural components).

Intelligent Temperature Control:

Employs fully automatic annealing furnaces with furnace temperature uniformity of ±3°C, coupled with precise dew point control, ensuring batch-to-batch performance consistency.

From Process to Quality Management "Dual Assurance"

Technological Breakthrough:

In surface treatment, employs special rolling technology and surface grinding processes to achieve a finer, more uniform titanium surface, reducing the occurrence of micro-defects and significantly enhancing the overall material surface finish.

Quality Management:

Establishes a comprehensive quality management system, providing each batch of products with a traceable "digital footprint." The process is transparent and controllable, from raw material inspection to finished product delivery.

Technology as the Foundation, Advancing Toward Innovation

Just as titanium metal itself combines strength with flexibility, Hongwang Titanium is building a new material ecosystem in consumer electronics, new energy, and aerospace through dual innovations in "Precision Intelligent Manufacturing + Digital Management." We actively contribute to technological innovation and industrial development within the sector.

Titanium in the Armament Industry:From Mortar to Tank

2026-01-19Influence of transformer core structure on performance

2024-11-27Stainless Steel Development in Pharmaceutical industry

2022-08-15Application of multi-air gap segmented core in anti-dc bias transformer

2025-03-11What Role do Laminations Play in Electric Motors and Generators?

2023-01-31The difference between 430 and 304 stainless steel

2022-12-01