Under the background of "dual carbon", all walks of life are accelerating the reduction of carbon emissions. As one of the key industries to achieve the "double carbon" goal, the iron and steel industry reduces carbon emissions not only in reducing carbon emissions in the production process, but also in significantly reducing carbon emissions in various applications through the application of advanced steel materials. As far as the automobile industry is concerned, the global automobile industry is currently transforming to new energy sources and accelerating the realization of electrification. Among them, my country's new energy vehicles are developing the fastest. The rapidly increasing production and sales of new energy automobile have strongly stimulated the installed demand for driving motors. Practice has proved that the use of high-grade non-oriented silicon steel to make motor stators and rotors can not only improve the efficiency of driving motors for new energy automobiles, but also further reduce carbon emissions, which contributes to energy saving and carbon reduction in the entire life cycle of steel materials.

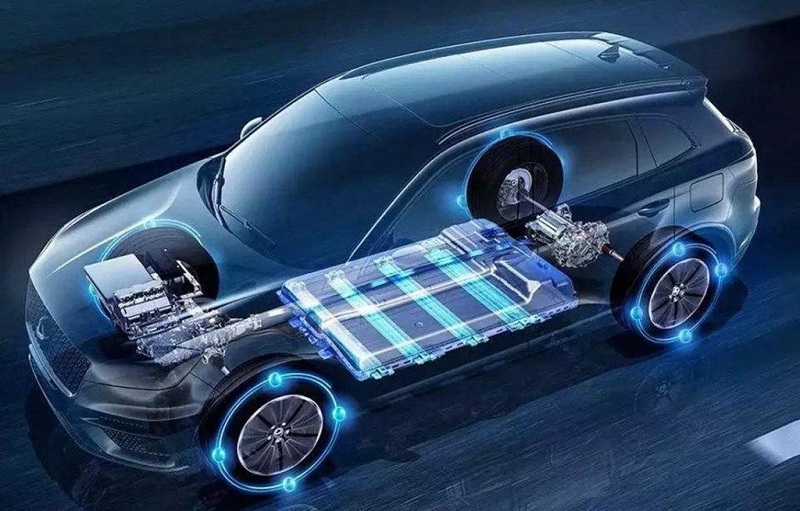

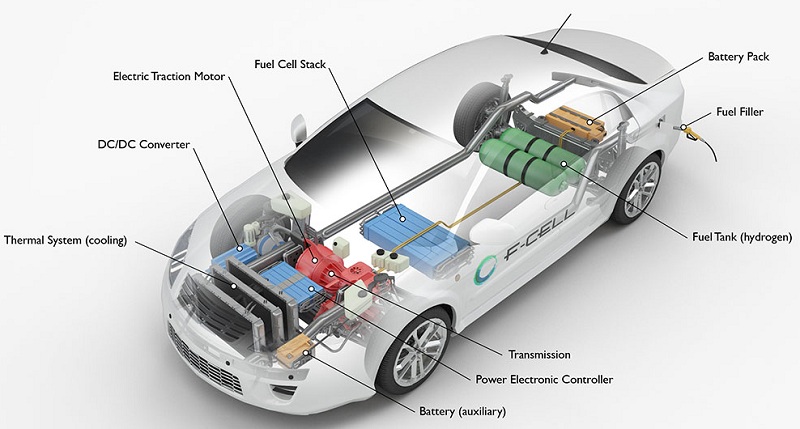

The driving power of new energy automobiles, especially energy automobile of class B and above, is generally above 180kW, and two or more sets of electric drive systems need to be equipped. As the proportion of high-end electric automobiles continues to increase, the installed capacity of new energy driving motors will further increase. With the advantages of high power density, low energy consumption, small size, and light weight, permanent magnet synchronous motors are the most widely used in China's new energy automobiles, accounting for 94.4% of the total installed capacity in 2021. Driving motor is one of the three core components of new energy automobiles, and its future development direction is high speed and high power. This requires the motor to reduce the volume, weight and iron loss of the motor as much as possible under the same power. But reducing the volume and weight of the motor will lead to a reduction in the torque of the motor, so the speed of the motor needs to be increased. For example, the speed of the Prius2015 motor is almost three times that of the Prius2004 motor, while the peak torque shows a decreasing trend. Through the cooperation of the high-speed motor and the gearbox, the high-speed low-torque input is transformed into a low-speed high-torque output, thereby achieving the purpose of driving new energy vehicles.

The high-speed and high-power driving motors also put forward higher requirements for motor materials, especially the stator and rotor cores made of laminated non-oriented silicon steel sheets, which not only directly determine the motor power, torque, iron consumption, temperature The upgrade also affects the cruising range of new energy vehicles. For example, the Nissan Leaf II, which was launched in Japan, North America, and Europe in 2018, has a battery capacity of only 40kWh, but a cruising range of up to 400km, which is the same as the Tesla Model S with a battery capacity of 60kWh. This is because Nissan Leaf II uses a permanent magnet synchronous motor as the driving motor, which is excited by permanent magnets and does not require excitation current, so there is no excitation loss, low loss, and high efficiency. In addition, the stator and rotor iron core of the Nissan Leaf II driving motor is made of laminated silicon steel sheets with a thickness of 0.25mm, which can reduce iron loss and further improve motor efficiency. The driving motor core of the 2016 BMW i3 is made of laminated silicon steel sheets with a thickness of 0.27mm. There are a large number of weight-reducing holes in the rotor core to reduce the weight of the motor and increase the power density of the motor. Therefore, in order to improve the efficiency and power density of the motor, the silicon steel sheet for the motor has been reduced from the traditional 0.35mm and 0.50mm to 0.25mm and 0.27mm. It is foreseeable that with the increase of motor speed, silicon steel with thinner specifications and lower iron loss will be gradually applied to new energy vehicle driving motors.

The cold-rolled non-oriented silicon steel sheet used to manufacture the stator and rotor cores of driving motors is the key soft magnetic material that determines the conversion of power and energy. The iron loss generated in the iron core is an important part of the motor loss, especially when the motor is running at a high speed, the proportion of iron loss to the total loss increases significantly. In the ultra-high frequency state, the eddy current loss alone accounts for 40%-70% of the total loss, so this requires silicon steel to have as low a high frequency iron loss as possible, which can improve the efficiency of the motor and increase the cruising range of new energy vehicles , It can also suppress the temperature rise and avoid the demagnetization of the permanent magnet; during the vehicle start and low-speed climbing stages, the motor needs to output a huge torque enough to drive the car to start, so it needs to have as high a magnetic induction as possible. In addition, the huge centrifugal force during high-speed operation and the strict design of the stator-rotor clearance also require the rotor material to have a higher yield strength. Therefore, new energy vehicle driving motors with high speed and high power density require the use of cold-rolled non-oriented silicon steel sheets with thinner specifications (≤0.35mm), lower high-frequency iron loss, higher magnetic induction, and high yield strength.

Oriented Silicon Steel and Non-oriented Silicon Steel

2025-10-13The difference between 430 and 304 stainless steel

2022-12-01A comparison of stamping, laser cutting and chemical etching

2023-07-03Comparison of Advantages and Disadvantages Between Seamless Cores and Traditional Laminated Cores

2024-12-105 Benefits Of Stainless Steel Tanker

2023-02-27Electrical steel enables new propulsion systems to enable future aviation development

2024-04-03