In high-end manufacturing sectors such as aerospace, medical devices, and marine engineering, titanium alloys have emerged as a core material due to their exceptional properties. Welding, a critical process for shaping titanium alloy components, directly determines the reliability and service life of the final products. Among various quality metrics, porosity analysis of welds stands as a pivotal step in evaluating internal defects within welded joints. It not only accurately assesses the rationality of welding processes but also provides scientific evidence for quality control, acting as the "Invisible Guardian" of titanium alloy product safety. Recently, "Titanium Home," a professional information platform in the titanium industry, published an in-depth report on this key inspection technology, highlighting its significant role in industry-wide quality management.

I. Comprehensive Insights: The Core Elements of Porosity Analysis

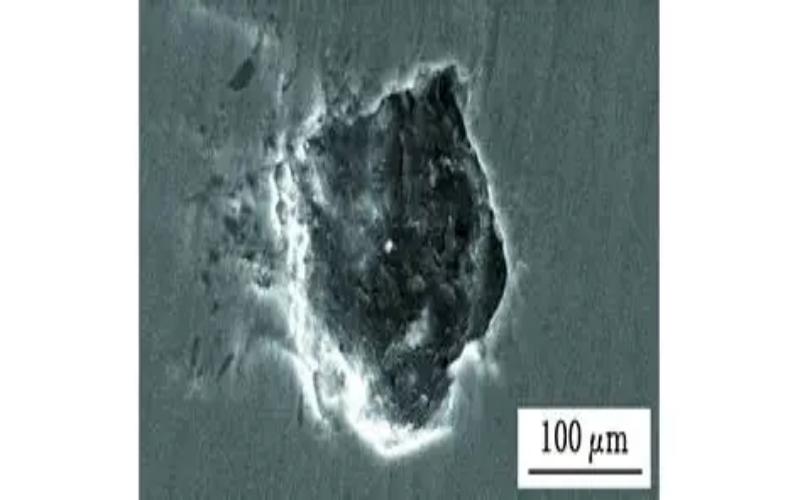

Porosity analysis for titanium alloy welds is not a singular test but a systematic, multi-dimensional evaluation designed to precisely characterize porosity features:

Pore Quantity Statistics: Accurately counts the total number of pores within the weld seam, laying the groundwork for subsequent quantitative analysis.

Pore Size Measurement: Determines the size parameters of individual pores to evaluate their impact on joint performance.

Pore Distribution Analysis: Reveals the distribution pattern of pores within the weld seam—whether clustered or evenly dispersed.

Porosity Calculation: Synthesizes the above data to determine the proportion of pores within the welded joint, quantitatively assessing the welding quality grade.

II. Broad Coverage: Detection Scenarios Across Multiple Fields

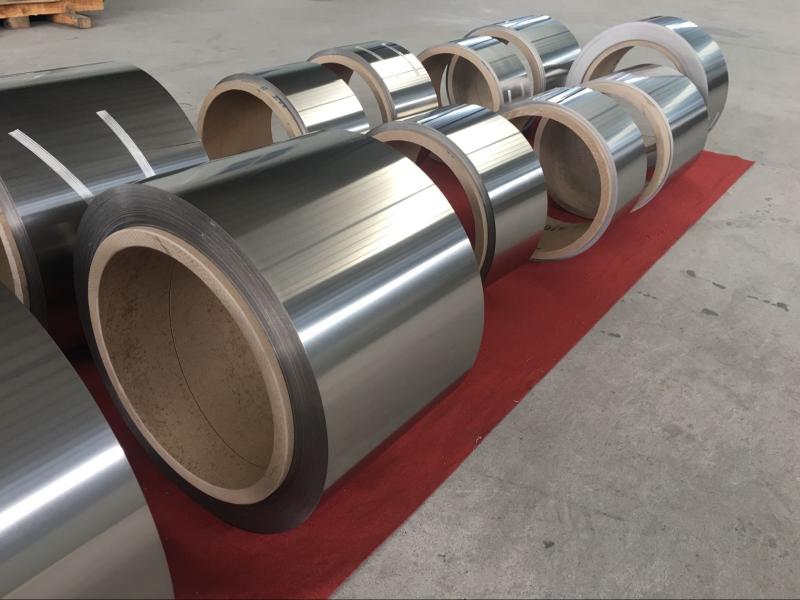

From laboratory samples to large-scale engineering components, and from conventional industrial equipment to cutting-edge precision instruments, porosity analysis is applied across nearly all fields involving titanium alloy welding:

Industrial Sector: Components like pressure vessels and pipelines operating under high-pressure conditions require inspection to ensure pressure resistance and safety.

Aerospace: Titanium alloy structural parts in aircraft; pore defects could compromise flight safety, making inspection essential.

Medical Devices: Welded parts such as implants are directly linked to human health, necessitating stringent control over porosity.

Marine Engineering: Corrosion-resistant components exposed to harsh environments over long periods; pores can accelerate corrosion, requiring precise detection.

Research and Development: Porosity analysis of welded samples is used to validate new processes and materials.

Compatibility with Various Welding Methods: Whether TIG, MIG, or laser welding, the resulting weld seams can be inspected using this technology.

III. Precise Detection: A Scientific Approach Combining Non-Destructive and Destructive Methods

To ensure reliable inspection results, porosity analysis employs a complementary combination of non-destructive and destructive testing methods:

X-Ray Inspection: Functions like an "X-ray of the weld," visually revealing the location, morphology, and distribution of pores.

Ultrasonic Testing: Utilizes acoustic wave reflections to accurately identify minute pore defects.

Metallographic Analysis: Involves sectioning and polishing samples to observe the microscopic characteristics of pores under a microscope.

CT Scanning: A three-dimensional imaging technique that comprehensively displays the spatial distribution of pores.

Density Measurement: Macroscopically estimates pore proportion by comparing actual density with theoretical density.

Common Combinations: X-ray inspection paired with metallographic analysis is often used for mutual verification, enhancing result accuracy.

IV. Professional Assurance: Advanced Instrumentation Strengthens Data Foundation

Accurate analysis relies on professional equipment, with a full suite of inspection instruments ensuring data reliability:

X-Ray Flaw Detector: Penetrates the weld seam to capture internal pore images, serving as the core equipment for non-destructive testing.

Ultrasonic Flaw Detector: High-frequency probes improve sensitivity, enabling the detection of minute pores.

Industrial CT System: High-resolution 3D imaging clearly displays the spatial distribution of pores.

Metallurgical Microscope: Paired with image analysis systems, it enables precise measurement of pore dimensions.

Density Measurement Device: Provides accurate density data to support macroscopic porosity calculations.

Auxiliary Equipment: Image analysis software digitizes data processing, while cutting and polishing equipment prepares qualified metallographic samples.

Critical Requirements: Instruments require regular calibration, and inspectors must undergo professional training to ensure precision in operation and analysis.

V. Future Outlook: Technological Innovation Drives Quality Advancement

Porosity analysis for titanium alloy welding represents the integrated application of material properties, welding processes, and inspection methods, requiring flexible selection of detection solutions based on specific scenarios. With technological advancements, new non-destructive testing techniques and intelligent analysis software are gradually being introduced: rapid and precise defect detection technologies shorten inspection cycles, while intelligent analysis systems enable automated data processing, significantly enhancing inspection efficiency and accuracy. These innovations will inject stronger momentum into titanium alloy welding quality control, driving quality upgrades in high-end manufacturing fields.

Hongwang’s exclusive brushing process technology

2023-02-09Production precautions of stainless steel coils

2021-02-08Why and how do the stator and rotor "roll"?

2024-03-22How are metal composites "compounded" together?

2023-11-16The difference between stainless steel and carbon steel

2021-08-18Hot rolled, cold rolled coils, silicon steel, steel coils where did they go

2023-10-24