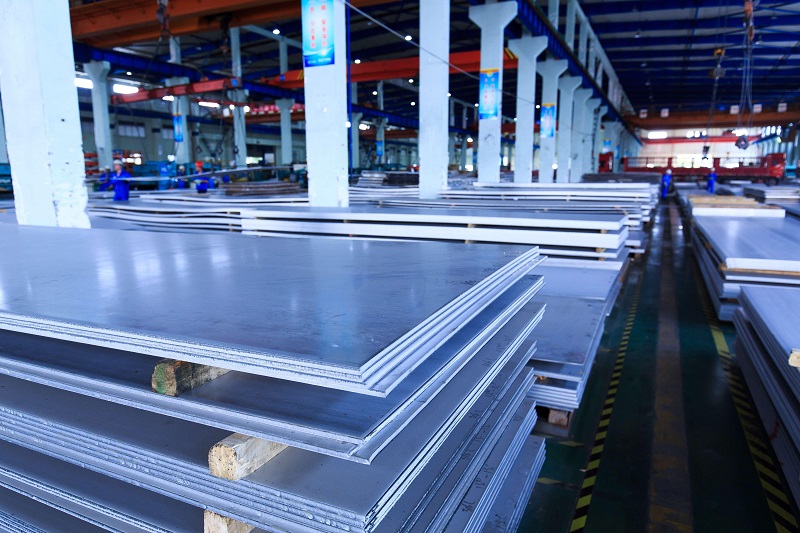

We generally teach you how to distinguish the quality of colored stainless steel from three aspects. First look at the material, the commonly used materials of color stainless steel plate are 201 stainless steel, 304 stainless steel. Among them, 304 stainless steel plate has higher corrosion resistance than 201 stainless steel plate, and the positive material is flat and bright than the calendering material. Because of the large price difference, many businesses are shoddy, using calendering material as positive material, and using 201 as 304. Therefore, the primary task of inspection is to verify whether the plate is specified material.

201 and 304 can be distinguished by detection liquid, while the positive material and calender are mainly distinguished by observing the quality of the board surface, the positive material surface is smooth and flat, uniform color, high brightness, and the thickness of the whole board is consistent, while the calender surface is dark, uneven color, often black or striped, the back has roller impression, sand holes, peeling water marks and other defects. The thickness difference of the board can reach 2 or 3 filaments.

However, with the improvement of the production process and technology of many large calender plants, the gap between positive and calender materials is slowly narrowing, and some imitation positive plates can even be fake and real, requiring professionals with rich experience to distinguish.

The second is the view effect, the color stainless steel plate is mainly used in the field of decoration, and the observation and decorative requirements of the board are very high. Good color stainless steel plate in direct sunlight should not be visible to the naked eye color difference, the whole batch of plates without color difference, uniform coloring, good color, no scratch bending does not fade. The surface of the stainless steel mirror plate should be free of grinding head flowers and horseshoe marks, and the brightness is high.

Finally, the color stainless steel plate will be affixed with a protective film before leaving the factory by tearing the film. Many unsalable plates, placed in the warehouse for a long time, the protective film will powder, it is difficult to tear, or after tearing, the surface of the plate is still stuck with a lot of glue, which is ugly and difficult to remove, time-consuming and laborious. Even if it is a transparent film, when we inspect the goods, we must tear a large piece to see the quality of the film. If subsequent cutting and bending is required, it is best to stick a protective film above 6C first to avoid scratching the surface of the board. After the installation of the color stainless steel plate, the film layer should be torn off as soon as possible, and must be stained with glue. Especially outdoor decoration, because of direct sunlight, it is best to tear off the protective film immediately after construction.

321 and 304 stainless steel corrosion resistance and high temperature performance

2024-07-06S30403 stainless steel and 304L stainless steel

2024-06-13Stainless steel dephosphorization problem

2024-07-31Laser and Innovation Lead New Trends in the Silicon Steel Market

2025-11-07The difference between 200, 300 and 400 series stainless steel

2023-10-09Unlocking New Trends in Amorphous Semiconductor Development with Intelligent Sensing: The 29th South Australia Science Conference Held

2026-01-27