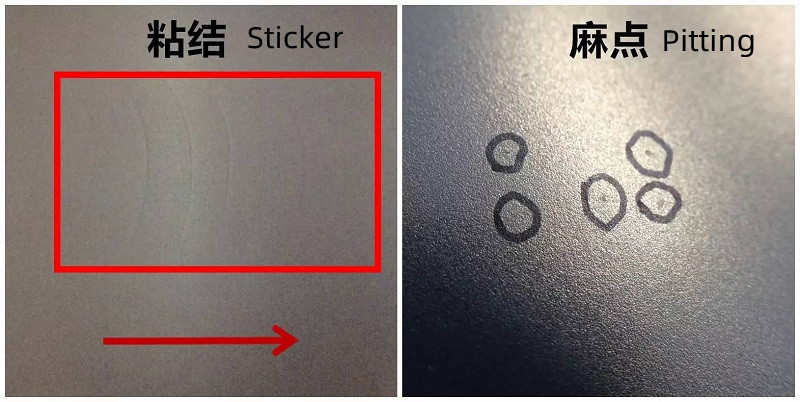

There are two annealing processes in the rolling process of cold rolled coils, batch annealing and continuous annealing. Batch annealing and continuous annealing are both cold rolling and annealing processes. But due to the different processes, the properties of the finished products are also different. There is no "Pitting" in the cover return, and there is no "Sticking" in the continuous return; the batch annealing materials is dirty, but the continuous annealing materials is clean. There is "Bruise" in the cover return, and there is "Scratch" in the continuous annealing materials.

We have popularized the characteristics of the steel coils of the two annealing processes, and these characteristics are all derived from the difference in the annealing process. What are the differences between batch annealing and continuous annealing processes? Batch annealing and continuous annealing are two different processes for post-rolling annealing of sheet cold rolling.

Batch Annealing

After the hot-rolled coils are cold-rolled, the semi-finished coils are piled up one by one, about two or three layers, and put into a cover annealing furnace, which is made like a big cover. Annealing room, temperature control, full annealing.

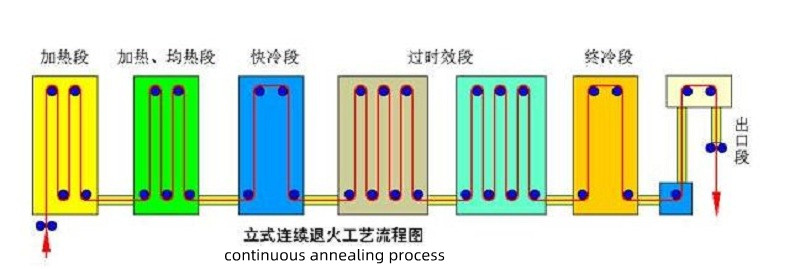

Continuous A nnealing

The cold-rolled coils are opened one by one, and connected end to end (welded together) through a large annealing furnace, which is serpentine, wound around inside, and finally wound out to complete annealing. Once the speed of the unit is controlled, the time from when the strip enters the furnace to when it exits the furnace is fixed. The speed and furnace temperature determine the duration of the heat.

After understanding the process, it is easier to further understand the characteristics of the two annealed materials:

The hood stripping is annealed in the coil state, and the strip steel is easy to stick together at high temperature, causing bonding defects, so the strip steel should not be too clean. Moreover, batch annealing has a steel-turning process, so it is easy to bruise.

The continuous annealing materials after unfolding, pitting is prone to occur when the high-temperature strip contacts with the furnace roll. And scratches may also occur due to the motion of annealing.

Both processes have their own advantages and disadvantages, and each has its own characteristics. Choosing batch annealing materials that are sensitive to pitting, and continuous annealing materials that are sensitive to surface cleanliness.

Electrical steel industry review and industry outlook

2024-02-18India Imposes Anti Dumping Duty on Indonesian Stainless Steel Coils

2021-01-21What is rainbow stainless steel?

2022-12-30Stainless steel surface treatment process- Mirror treatment

2020-11-19Various Classifications of Colored Stainless Steel

2022-06-16SUS304, 304, 06Cr19Ni10 three names of the same kind of steel

2024-07-09