The production of stainless steel sheet is usually by cold rolling method, of which cold-rolled stainless steel is mainly produced by rolling method, and only small batch stainless steel sheets of individual steel numbers will be produced individually. Sheet rolling is suitable for the production of large specifications of thicker steel plates and trial production of new steel grades.

The production process of cold-rolled stainless steel strip includes heat treatment, pickling and grinding of hot-rolled steel strip. Smooth; Cross cut into steel plate or longitudinally cut into steel strip; Categorize; Clean and pack.

For high efficiency and high precision rolling, it is necessary to adopt rigid multi-roll cold rolling mill. Multi-roll cold rolling mill generally adopts single-machine reversible rolling mode. In order to improve the yield, the lead strip is welded at both ends of the stainless steel strip before rolling, and the lead strip part is not rolled. The stainless steel strip needs to be annealed before cold rolling, the intermediate annealing is also required during the cold rolling process, and the final product needs to be annealed. Cold-rolled stainless steel strip has strict requirements on surface quality, and a series of elimination and protection measures have been taken, such as shot blasting, pickling, grinding and so on. The finishing requirements of stainless steel tape are special, and it is necessary to use a strong straightening machine for straightening, and different straightening methods are used according to different thickness products.

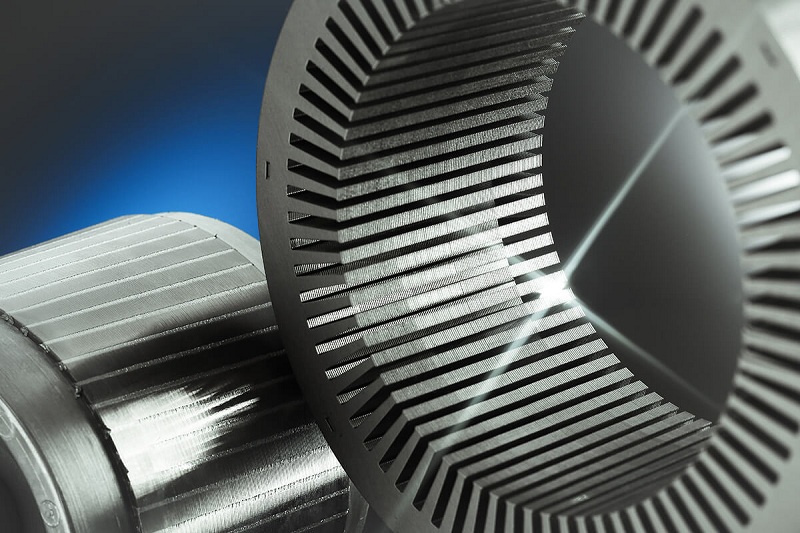

The production technology of cold rolled stainless steel strip includes the type of cold rolling machine, friction coefficient, front and rear tension, rolling speed and roll. The type of cold rolling mill requires the use of a large rigid mill, and the multi-roll cold rolling mill has more advantages than the four-roll mill. The friction coefficient is achieved by using rolling lubricants to reduce the friction coefficient on the contact surface between the roll and the steel strip while cooling the roll and the steel strip. The front and back tension has an effect on the rolling pressure, and the cold-rolled stainless steel strip requires greater tension. The change of rolling speed will affect the friction coefficient between the roll and the steel strip, thus affecting the rolling pressure and the thickness of the steel strip. Roll must have high hardness, strength and wear resistance, but also have a certain toughness. The reduction system includes the regulation of rolling pass, reduction amount and rolling process, which is determined according to the characteristics of the mill and product requirements.

The aim of plate shape control is to roll out strip with uniform transverse thickness and straight shape, which is achieved by adjusting the shape of the load roll gap. Thickness control depends on improving the rolling precision of cold rolling, which is realized by automatic thickness control device. The production process of cold-rolled stainless steel strip includes heat treatment, pickling, grinding, leveling, cross-cutting, sorting, cleaning and packaging steps.

201 STAINLESS STEEL INTRODUCTION J1/J2/J3/J4/J5

2021-10-19Silicon steel sheet: the core and performance cornerstone of motor magnetic circuit

2025-10-27What should we pay attention to when selecting stainless steel colored sheets

2021-10-26You're right if choose a stainless steel sink like this

2021-11-16Brief classification of silicon steel

2022-09-09Status &Analysis of Demand for Stainless Steel in Petrochemical Industry

2022-08-02