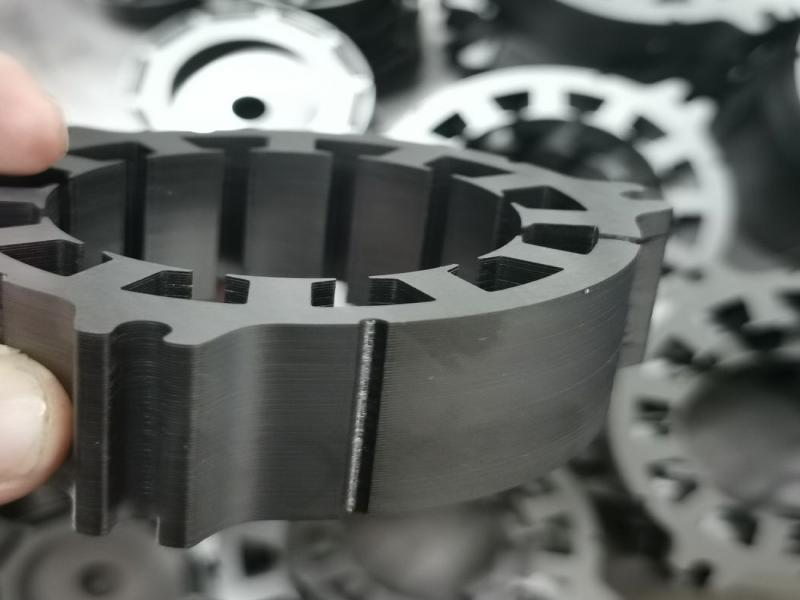

In the precision world of motors, silicon steel sheets play an irreplaceable and crucial role. As a magnetic material, it is the core medium for constructing efficient magnetic circuits and transmitting magnetic forces. The essence of motor design can be summarized into three main elements: magnetic energy design, electrical energy design, and magnetic circuit design. Among them, the influence of magnetic circuit design is the most profound and decisive. Once the size, shape, and magnetic circuit structure of the magnetic material (mainly silicon steel sheets) are determined, the maximum output capacity that the motor can ultimately achieve is basically finalized. Even if the performance of the magnet is significantly enhanced in the future (such as using stronger permanent magnets) or the input of electrical energy is increased (such as increasing current), it will be difficult to effectively break through this "ceiling" set by the magnetic circuit design, and the improvement of its output capacity will become extremely limited and inefficient. Therefore, the selection of silicon steel sheets and optimization of magnetic circuits are fundamental to motor design.

Classification and Development of Silicon Steel Sheets

Silicon steel sheets are mainly divided into two categories: hot-rolled and cold-rolled. Cold rolled silicon steel sheets have basically replaced hot-rolled silicon steel sheets in modern industry due to their significant advantages such as good thickness uniformity, high surface quality, and superior magnetic properties (low iron loss, high magnetic induction intensity).

Cold rolled silicon steel sheets are further divided into:

Non oriented Electrical Steel (NOES): The grain arrangement direction is random, and the magnetic properties are relatively uniform in all directions. This is the most commonly used material for motor iron cores (stator and rotor) because the direction of the magnetic field inside the motor changes in rotation.

Grain oriented Electrical Steel (GOES): The grain height is preferentially oriented, with extremely high magnetic induction intensity and low iron loss along the rolling direction, but poor performance in other directions. Mainly used for equipment such as transformers where the magnetic field direction is relatively fixed.

Core performance indicator: a ruler for measuring the quality of silicon steel sheets

When selecting and applying silicon steel sheets, it is necessary to pay attention to their key performance indicators:

1、Core Loss/Iron Loss: This is the most critical indicator for measuring the quality of silicon steel sheets. The energy consumed by silicon steel sheets during the process of alternating magnetic field magnetization is ultimately dissipated in the form of thermal energy. The lower the iron loss value, the higher the grade of silicon steel sheet, the better the material quality, and the higher the efficiency of the motor or transformer. Iron loss is mainly composed of hysteresis loss, eddy current loss, and additional loss (abnormal loss).

2、Magnetic Induction (B): Refers to the magnetic flux density that can be generated per unit volume of silicon steel sheet under a given magnetic field strength (H). A higher magnetic induction intensity means that a stronger magnetic field can be established at the same magnetic field strength, or a smaller excitation current is required to achieve the same magnetic flux density. This allows motors or transformers made from this material to be designed to be more compact (miniaturized), lightweight, and efficient.

3、Stacking Factor/Lamination Factor: refers to the ratio of the net volume of effective material of silicon steel sheets in the iron core to the total volume including inter sheet insulation and voids. A high stacking coefficient means that the silicon steel sheets are stacked more tightly and the air gap between the sheets is smaller. This directly reduces the magnetic resistance of the magnetic circuit, increases the magnetic permeability, and thus improves the overall efficiency of the equipment. The flatness and surface insulation coating thickness of silicon steel sheets will affect the stacking coefficient.

4、Thickness: The thickness of silicon steel sheets directly affects their eddy current losses (eddy current losses are proportional to the square of the sheet thickness). Therefore, high-frequency applications such as high-speed motors and switching power transformers typically use thinner silicon steel sheets (such as 0.10mm, 0.15mm) to suppress eddy current losses; For low-frequency applications such as power frequency motors and large transformers, relatively thick silicon steel sheets (such as 0.30mm, 0.35mm) can be used to reduce costs and ensure mechanical strength.

Development Trends and Design Thinking

A deep understanding of the characteristic parameters of silicon steel sheets and their significance in simulation and practical applications is crucial for motor engineers to enhance their professional design capabilities. Throughout the technological development trajectory of silicon steel sheets, continuously reducing iron loss is undoubtedly the core goal pursued by material developers and motor designers for a long time.

However, a key design insight is that for most types of motors, especially small and medium-sized induction motors and permanent magnet motors, the main source of loss is often not iron loss, but copper loss (I2 R loss) in the windings. This reminds us that when optimizing motor efficiency, we need to consider the whole picture.

Indeed, the performance of silicon steel sheets (especially their saturation magnetic induction intensity Bs and iron loss) largely constitutes the "bottleneck" in motor design. But the direction of breaking through bottlenecks is not limited to blindly pursuing lower iron losses. How to effectively improve the working magnetic flux (Φ) of the motor magnetic circuit, in order to obtain greater torque or power density under the same volume, or reduce volume and material usage under the same performance requirements, is often a more challenging and valuable goal. Higher magnetic flux requires silicon steel sheets to have higher saturation magnetic induction intensity, while also requiring magnetic circuit design to fully utilize the material's magnetic properties. Therefore, in motor design, "increasing magnetic flux" and "reducing losses (including iron and copper losses)" need to be optimized synergistically, and the former is often a key consideration indicator for improving motor power density and performance limits. A deep understanding of the performance of silicon steel sheets and a clever conception of magnetic circuit design are the keys to solving this problem.