Many people know a little about stainless steel color plate, but what should we pay attention to when selecting stainless steel colored sheets? How can you choose to make suppliers think you are an expert for stainless steel material?

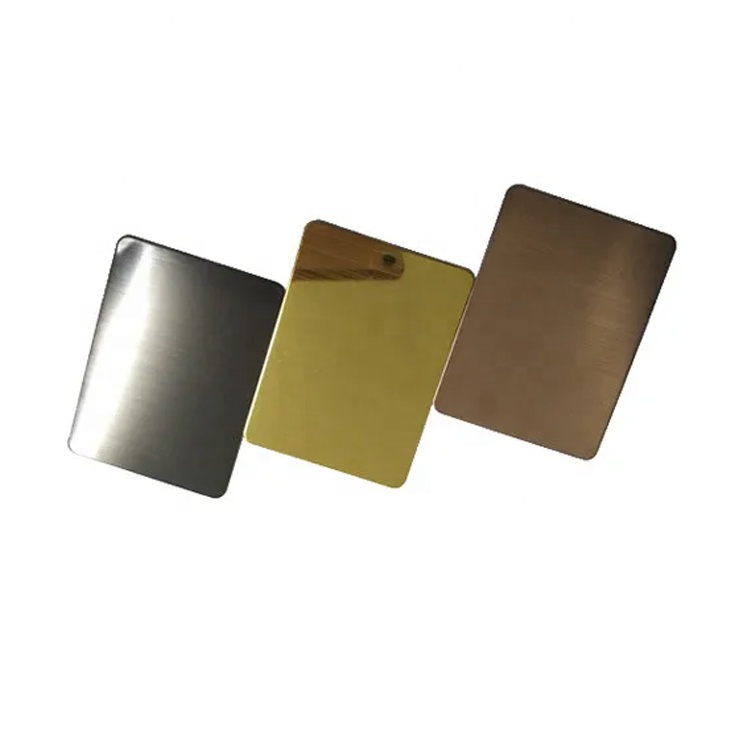

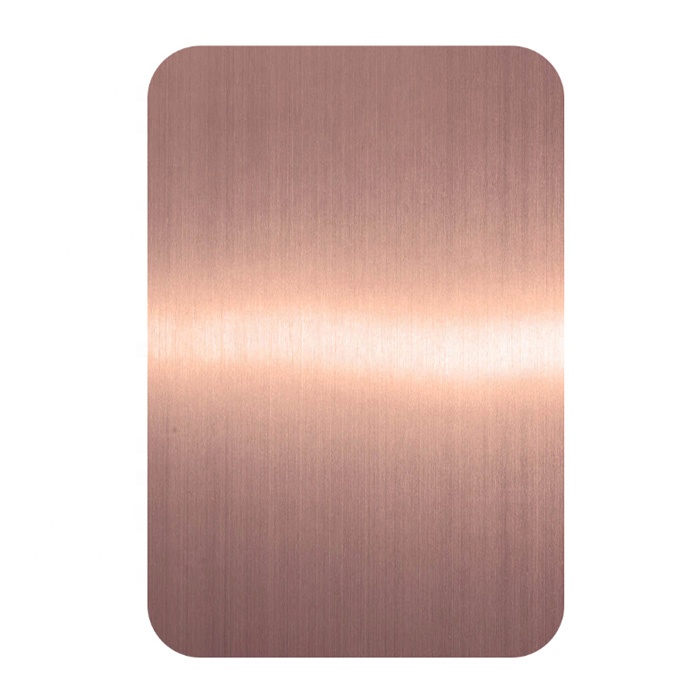

When selecting stainless steel color plates, we first observe the stainless steel material surface. Because the colored stainless steel sheet is mainly used for architectural decoration, ornamental is particularly important. When inspecting the decorative stainless steel sheets, consumers need to strictly check and observe whether there are color differences, scratches, sand holes, peeling water marks and other problems on the stainless steel material surface.

Then the second step is to identify the stainless steel surface coloring process

The surface coloring process of stainless steel will affect the price.

Water plating coloring: it gives people an unreal and delicate feeling, just like spraying, which will also produce waste water pollution and low price.

Vacuum plating coloring: relatively environmentally friendly, it will not produce toxic or polluting substances, so the price is relatively high.

The third step is to observe the quality of the film

The surface of colored stainless steel sheet is usually pasted with a protective film to ensure the surface smoothness and avoid being scratched by hard objects. If the protective film with poor quality is kept for a long time, it will be powdered and difficult to tear, or a lot of glue will stick to the surface after tearing. During inspection, it is recommended to tear a large area to check the quality of the film.

Finally, distinguish the material and technique, which is most important!

The commonly used materials of colored stainless steel sheets on the market are 201, 304, 316 and other grades. Among these grades, 316 has the best corrosion resistance, while 201 is the most reasonable, so it caused a large price difference. Choose the most suitable stainless steel material for your construction and production. Therefore, some fake suppliers often use 201 instead of 304 and 316. Some businesses will use the water plating coloring process to replace the vacuum ion plating coloring process, resulting in the problems of color falling off, rust and even fracture on the surface when installing stainless steel sheets in many building decoration projects.

Advantages of stainless steel water pipes

2021-07-19The "Resume" of a Stainless Steel Pot: From Aerospace Material to Your Kitchen

2025-10-17Why and how do the stator and rotor "roll"?

2024-03-22Electrical steel industry analysis

2023-11-20The nature of national standard 304 stainless steel and stainless steel types

2021-01-19What are the design features of modern stainless steel screens?

2022-07-28