Current Location : Home > News > Industry News > Why is there a fingerprint-free process when plating a stainless steel plate?

Why is there a fingerprint-free process when plating a stainless steel plate?

Time:2021-08-04

Source:Wuxi Hongwang

Hits:539

The surface color of stainless steel plates has changed from 2B (no surface processing) at the beginning to bronze, rose gold, elegant black and so on. From this situation, we can see that the development of 304L stainless steel color plate is getting better and better. However, there is a very strange phenomenon, that is, why is there a fingerprint-free process when plating stainless steel plates?

What is no fingerprint?

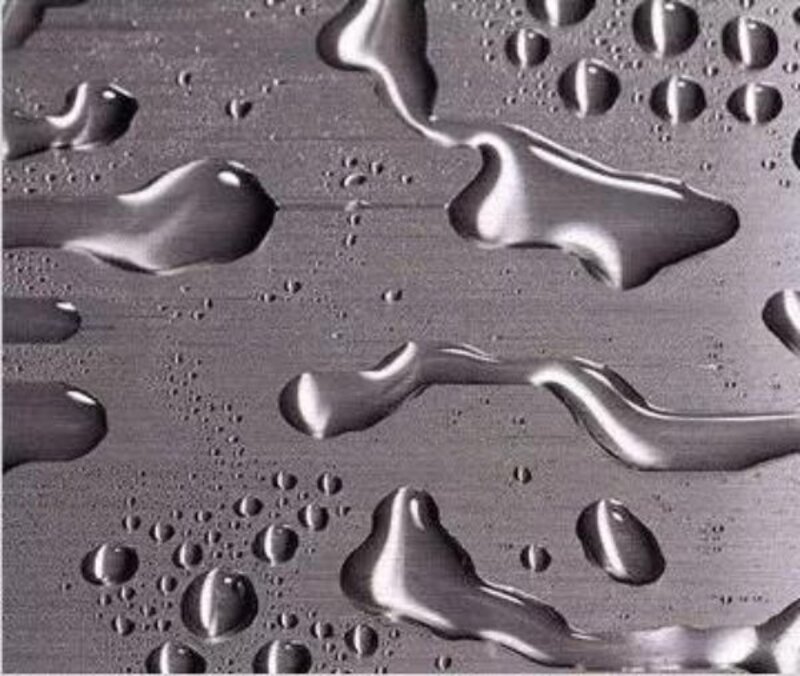

Stainless steel materials on the market are generally divided into 2 series stainless steels, 3 series stainless steels, and 4 series stainless steels. The 2 series stainless steels have higher iron content and carbon content, resulting in lower overall performance, poor strength and corrosion resistance, generally Use of low-end products. 3 series stainless steel is preferred, among which the 304 and 316 series are the most commonly used.Stainless steel non-fingerprint plate refers to a protective layer of transparent colorless to light yellow liquid coated on the surface of the stainless steel color plate. After this transparent nano metal roller coating liquid is dried, it will be combined with various texture color stainless steel decorative plates. The surfaces are firmly combined to form a transparent, hard and solid protective film, which improves the anti-fingerprint type, anti-pollution type, corrosion resistance and wear resistance of the stainless steel plate.For high-end electronic components, import and export products, it is recommended to use 316 series stainless steel.

No fingerprints

The stainless steel decorative board is processed by advanced fingerprint-free technology to increase the beauty and durability of the metal decorative board. Its main purpose is to prevent people from leaving fingerprints on the surface when touching these boards, so that the surface will not be stained with oil, sweat, dust, etc. Tarnished. The fingerprint-free process has changed the previous problem that the surface of colored stainless steel will leave obvious fingerprints when touched. There is also a titanium-plated color film on the stainless steel surface. If the quality is not good enough, the color film will easily fall off after a long time. Therefore, the fingerprint-free process will also make the color stainless steel surface gloss more durable and long-lasting, reducing the time for daily maintenance. The fingerprint-free process will not damage the appearance of the base layer. At the same time, the color film will not peel off, and the stains can be completely removed by wiping with a dust-free cloth. The non-fingerprint board is generally made of high-quality stainless steel board first, processed by dozens of processes such as cutting, pressing, bending, forming, welding, oiling, sanding, etc., into various colored stainless steel decorative boards, and finally the surface is processed without fingerprints.

What are the advantages of no fingerprints?

1. It is easy to clean surface stains and does not require metal cleaning agents. Some chemical agents will make the surface of stainless steel plates black; and it is not easy to stick fingerprints, dust, and feel delicate. It has super fingerprint and anti-fouling effects.

2. The fingerprint-free transparent film layer can protect the metal surface from scratching easily, because the surface electroplating gold oil has good film properties, high hardness, and it is not easy to peel, chalk, and yellow.

3. The appearance has strong texture, with oily moisturizing, soft hand feeling, and retains a good metallic texture.

4. The non-fingerprint board changes the cold and dull characteristics of metal, and looks warm, elegant and decorative.

5. The color stainless steel non-fingerprint plate has excellent anti-rust performance. A protective film is formed on the metal surface to effectively prevent the outside from corroding the inside of the metal, and the service life is greatly extended.

1. It is easy to clean surface stains and does not require metal cleaning agents. Some chemical agents will make the surface of stainless steel plates black; and it is not easy to stick fingerprints, dust, and feel delicate. It has super fingerprint and anti-fouling effects.

2. The fingerprint-free transparent film layer can protect the metal surface from scratching easily, because the surface electroplating gold oil has good film properties, high hardness, and it is not easy to peel, chalk, and yellow.

3. The appearance has strong texture, with oily moisturizing, soft hand feeling, and retains a good metallic texture.

4. The non-fingerprint board changes the cold and dull characteristics of metal, and looks warm, elegant and decorative.

5. The color stainless steel non-fingerprint plate has excellent anti-rust performance. A protective film is formed on the metal surface to effectively prevent the outside from corroding the inside of the metal, and the service life is greatly extended.

According to the characteristics of the stainless steel decorative board and the previous finished product test data, the fingerprint-free process must be adopted to complete the protection of the board surface. The same color-plated bead board, the fingerprint-free part and the non-fingerprint-free part, are very different in the effect of resisting the same external pollution. Colored plates that have been made without fingerprints, after bending and cutting, the inventory and use time is much longer than that of non-fingerprinted colored plates. As for the color-plated plates that have been protected by the fingerprint-free process, no abnormalities such as discoloration of the plate surface occurred in the same environment, because the fingerprint-free oil forms a protective layer on the plate surface, which effectively isolates the pollutants in the air from corroding the plate surface.

Related News

Application of titanium in large passenger aircraft

2025-12-11The "Resume" of a Stainless Steel Pot: From Aerospace Material to Your Kitchen

2025-10-17You're right if choose a stainless steel sink like this

2021-11-16Stainless steel soft material related knowledge and characteristics

2021-09-23Effect of heat treatment on microstructure and hardness of stainless steel

2024-07-03What is Stainless Steel Corrugated Board?

2021-07-21