The development of the C919 large passenger aircraft, fully independently developed by China, began in 2008. On November 2, 2015, the first prototype was rolled off the production line and tested at Shanghai China Commercial Aircraft Co., Ltd. It made its maiden flight on May 5, 2017, followed by its first cross-country flight on November 10. On December 17, the second C919 aircraft successfully completed its maiden flight at Shanghai Pudong International Airport, marking the entry of domestic large aircraft into a new phase of comprehensive testing and flight trials. Although the prototype used entirely foreign materials, primarily for the purpose of obtaining airworthiness certification, starting from the second aircraft, the use of domestic materials increased significantly, with each subsequent batch surpassing the previous one in quantity and year by year.

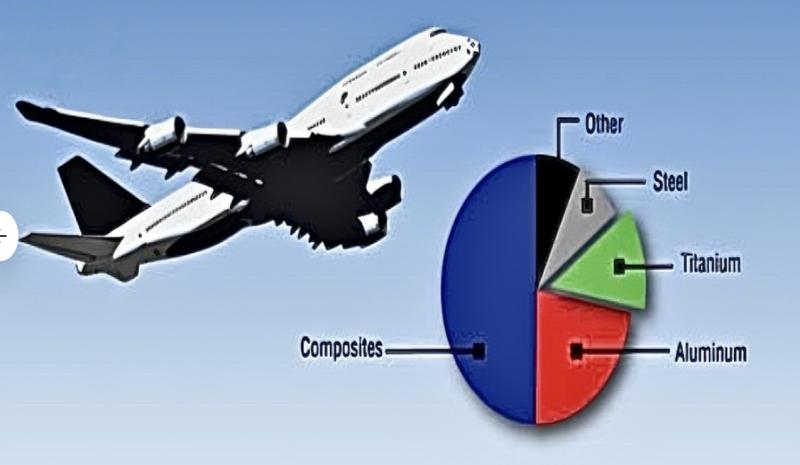

Titanium materials have been widely used in the manufacturing of large civil aircraft. Some key components of landing gears and wheels are forged from titanium alloys, while a small number of parts are forged from aluminum alloys. In the C919 large aircraft, the net mass of titanium alloy components accounts for about 10% of the total net mass of the aircraft. Among civil aircraft manufactured in China, titanium is the most extensively used material. Which components are made of titanium (see Figure 1): the nose uses Ti-6Al-4VEVI forgings; the suspension uses Ti-6Al-4V alloy forgings, plates, and Ti-55531 alloy forgings; the tail fin uses Ti-6Al-4V alloy forgings; the outer wing uses Ti-6Al-4V alloy forgings and plates; the central wing uses Ti-6Al-4V ELl alloy forgings; and the landing gear system uses Ti-6Al-4V alloy forgings.

Ti-6Al-4V (TC4, GB/T3620) is a medium-strength (over 900MPa) α+β type alloy developed by the U.S. Watertown Arsenal in 1954. It is widely used in the aerospace industry, with its semi-finished product output accounting for 55%-65% of the global titanium material production. It is used to manufacture various aerospace forging and sheet materials. Due to its excellent comprehensive performance, moderate price, early formation, in-depth research, longest usage time, and broad application fields, this alloy has maintained vigorous vitality for 67 years since its inception. The alloy is designated as TC4 in China, Ti-6Al-4V by Timet, RMI 6Al4V by American Active Metal, IMI318 by British Titanium, BT6 by Russia, ST-AI40 by Sumitomo Metal Industries of Japan, TA6V by France, and LT31 by Krupp of Germany. When used in the annealed state, TC4 alloy can be strengthened by heat treatment but has poor weldability. The "ELI" in Ti-6Al-4V ELI stands for Extro-Low Interstitial titanium alloy, which is suitable for low-temperature applications as α and α+β titanium alloys. Their strength performance increases with decreasing temperature, and their toughness decreases very little with decreasing temperature, making them suitable for manufacturing low-temperature structural components. The oxygen content of low-temperature titanium alloys is very low, reduced from 0.2% oxygen in ordinary grades to ≤0.12%, allowing them to be used at extremely low temperatures (<77K). Typical alloys include Ti-5Al-2.5Sn (ELI) and Ti-6AI-4V(ELI).Ti-5Al-2.5Sn. ELI is an American alloy that emerged in the early 1960s and was successfully replicated by China in the late 1970s, with the grade TA7 (China military standard GJ B495).Ti-5Al-2.5Sn). ELI alloy is particularly suitable for liquid fuel storage tanks operating at-255°C. Both of these titanium alloys, China Baotai Group, can provide sufficient supplies.

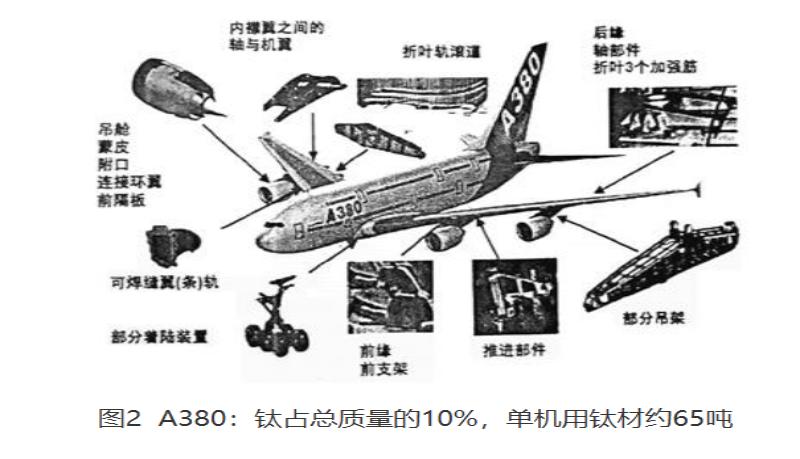

The Airbus A380, Europe's largest wide-body passenger aircraft, is the world's most titanium-intensive civil aircraft. Titanium alloy components account for approximately 10% of the total net weight, with a single aircraft consuming about 65 tons of titanium. Key titanium alloy components (see Figure 2) include: engine nacelle, skin, flanges, connecting ring wings, front bulkhead, shafts between inner flaps and wings, folding rail tracks, trailing edge, shaft components, three folding rib reinforcements, engine section brackets, propulsion components, leading edge, front brackets, partial landing gear, and weldable wing (bar) rails.

Development Status of High end Silicon Steel Market

2025-11-10The Role of Transformers in Renewable Energy

2024-11-30Popular Material For Straps - Stainless Steel Material

2022-08-29Stainless steel smelting method

2021-01-28Brief classification of silicon steel

2022-09-09A kitchen knife can't pat garlic? Stainless steel has a temper!

2022-07-20