How can we defy the inherent fate of steel—corrosion?

The answer lies within this thin yet formidable layer of "Zinc" Armor.

What is Hot-Dip Galvanizing?

Hot-dip galvanizing is a process where steel substrates are immersed in molten zinc. This triggers a metallurgical reaction between the zinc and the iron base, creating a series of zinc-iron alloy layers that bond the coating to the steel.

This coating does more than just provide a physical barrier. Because zinc is chemically more active than iron, it provides long-term cathodic protection through the electrochemical principle of "sacrificial anode." Even if the coating is partially damaged, the zinc will corrode preferentially to shield the underlying steel. Today, it has become the standard protective choice across steel structures, automotive manufacturing, home appliances, construction, and beyond.

Material Intelligence: Beyond Just Protection

Value Beyond Boundaries:Hot-dip galvanized materials push protective potential to the limit, creating core value that spans the entire product lifecycle.

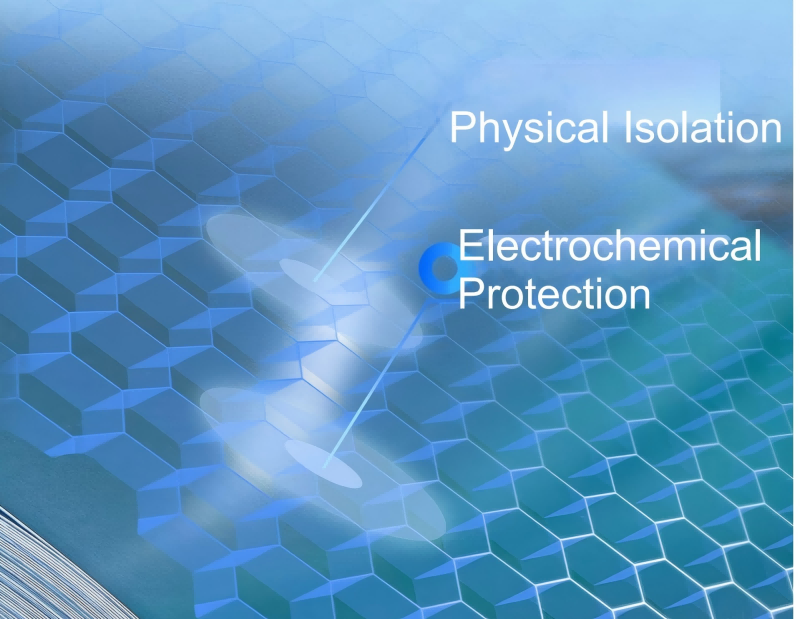

Dual Protection Mechanism:The zinc-iron alloy layer and the pure zinc layer formed on the surface constitute a dual defense line: "Physical Isolation" and "Electrochemical Protection." Even when faced with scratches, the zinc continues to act as a sacrificial shield, preventing rust from spreading.

Connecting the Protective Veins of Modern Industry: Versatile Applications

With its reliable protective performance and excellent processing adaptability, hot-dip galvanized materials deeply empower various sectors of modern industry.

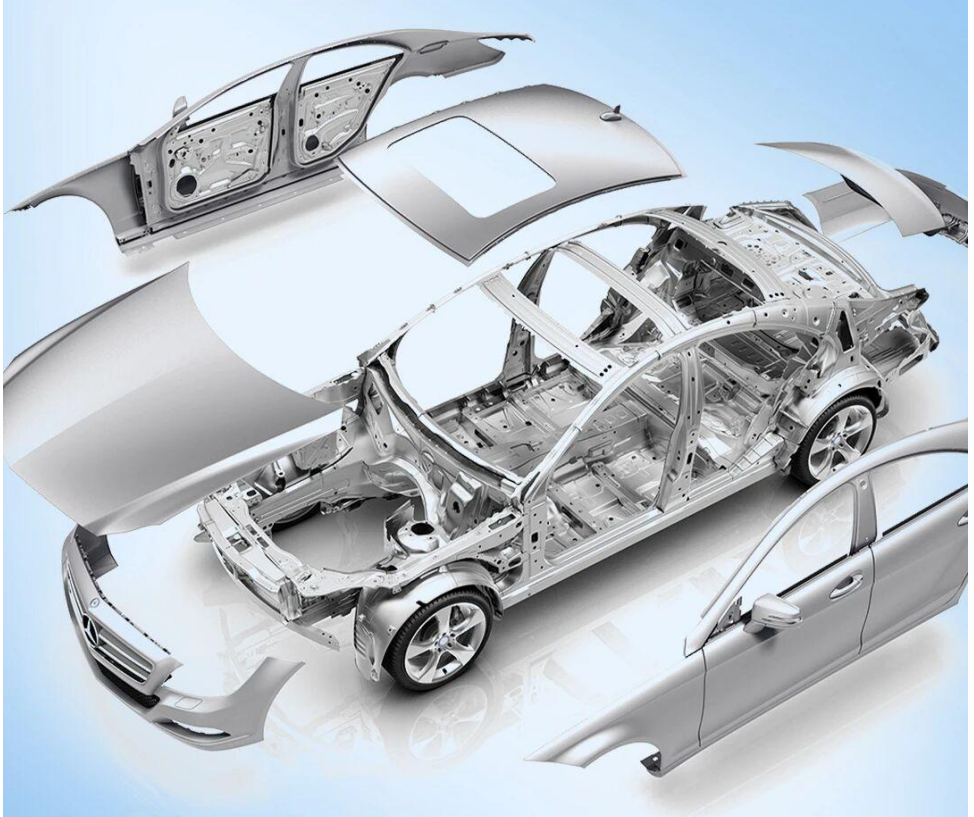

Automotive Sector

Providing a dual guarantee of high strength and superior corrosion resistance for lightweight body structures, battery pack brackets, and chassis components, ensuring vehicle safety in complex environments.

From high-efficiency Silicon Steel to breakthrough Amorphous Alloys; from precision-engineered Cores to lightweight and corrosion-resistant Titanium—Hongwang (HWHG) extends its deep expertise in advanced metallic materials into the realm of long-lasting protection with Hot-Dip Galvanizing.

Through innovative protective solutions, we continue to expand the boundaries of industrial empowerment, exploring the depths of material performance to reach the heights of the future.

Allowing every coil of steel to carry a more enduring mission.

Look forward to the next flower with Hongwang.

2023-06-08Countermeasures of Cold Rolled Stainless Steel Strips Coiling Defects

2022-07-13Hong Wang Stainless Steel Solid Color Series

2023-03-24The global motor iron core market will reach 18.97 billion US dollars In 2023

2023-12-21A comparison of stamping, laser cutting and chemical etching

2023-07-03South African Miners Rush to Transport Metals

2021-01-26