Silicon steel is an indispensable soft magnetic material in power, electronics and military industries. Driven by national policies, the new energy automobile industry has developed rapidly, and the demand for non-oriented silicon steel for new energy vehicles has shown explosive growth. Before the research and development of this project, ultra-thin non-oriented silicon steel for new energy vehicles and high-grade non-oriented silicon steel use the same annealing furnace production, there is no professional thin strip production annealing furnace, the output is low, product performance (such as iron loss) and foreign advanced level (such as Japan) there is a certain gap and unstable performance problems. The main problems are that the annealing furnace of high grade non-oriented silicon steel usually adopts the way of full radiation tube heating or open fire heating + radiation tube heating. There are some problems in the production of ultra-thin non-oriented silicon steel, such as low heating rate, weak oxidation of strip steel and poor heating uniformity. Because of the lack of research on the cooling characteristics of the equipment in the cooling control section and the lack of cooling adjustment means, the requirements of ultra-thin silicon steel precise cooling control cannot be realized, and the problem of strip edge wave is prominent. The furnace pressure fluctuates greatly, the atmosphere cannot be accurately controlled, and hydrogen cannot pass through the cooling section. Therefore, it is urgent to develop new annealing furnace technology and equipment, achieve more stringent annealing process requirements, and crack the bottleneck of ultra-thin non-oriented silicon steel production for new energy vehicles.

A new furnace type is innovatively proposed, which can meet the process requirements of heating rate ≥30℃/s, cooling rate ≤10℃/s, hydrogen ratio in the furnace 90%, and hydrogen flow in the cooling section, and can stably produce a full range of silicon steel products for electric vehicles. Among them, the developed high temperature and high frequency induction heating technology and equipment with protective atmosphere based on series power supply technology and intelligent closed-loop control technology break the foreign monopoly, and the temperature deviation of strip steel is controlled at ±5℃.

Green and efficient indirect heating equipment technology has been developed. Under high temperature (1050℃), the thermal efficiency of the radiant tube burner is increased by 5%, reaching 65~70%. Nitrogen oxide emissions are reduced by 50mg/Nm3 and stabilized below 150-180mg /Nm3(8% base oxygen) to achieve green and low-carbon production. For the first time, the diffusion combustion technology was introduced into the radiant tube indirect heating system, and the continuous ratio + pulse combustion control technology was developed, and the furnace temperature control accuracy was stable within ±4℃. To solve the problem of rapid and uniform heating of silicon steel for new energy vehicles.

In order to solve the problem that silicon steel for new energy vehicles needs accurate cooling control and accurate atmosphere control, an accurate cooling control technology based on online intelligent optimization control system is developed to eliminate the edge wave defect of strip steel and improve product magnetism. Innovative furnace pressure control equipment technology, furnace pressure control accuracy increased by 50%, furnace pressure fluctuation can be controlled in -3Pa~4Pa, suitable for 90% hydrogen atmosphere.

Through the above integrated innovation of key technologies such as high frequency induction heating equipment technology with atmosphere, green and efficient indirect heating equipment technology, high precision controlled cooling equipment technology, and precise atmosphere control technology, the ultra-thin non-oriented silicon steel annealing furnace technology and equipment for new energy vehicles have been developed.

In terms of induction heating power supply technology: innovative development of voltage series power supply technology and the development of matching inverter side technology, strip steel contact sensor no danger of electric shock, higher safety, the power adopts series resonance, open circuit and short circuit protection is easy. The core inverter module has high maintainability and low spare parts cost.

The successful development and implementation of this project has greatly promoted and led the iterative upgrading of China's silicon steel annealing furnace technology, enhanced the international competitiveness of China's metallurgical engineering equipment, and also created favorable conditions for the development of China's metallurgical engineering equipment "Belt and Road" market.

The chemical industry brings opportunities for the development of stainless steel

2024-04-23How to distinguish 304 stainless steel sheet and 201 stainless steel sheet?

2021-01-13Reasons of Cold Rolled Stainless Steel Strips Coiling Defects

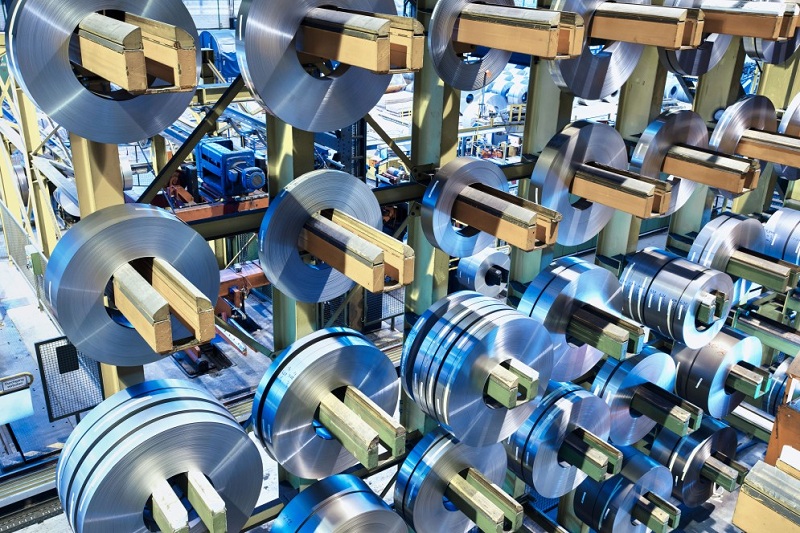

2022-07-12Electrical Steel Production Base--Hunan Hongwang

2023-01-11Why Apple Mobile Phones Love Stainless Steel So Much?

2022-08-09Comparison of Advantages and Disadvantages Between Seamless Cores and Traditional Laminated Cores

2024-12-10