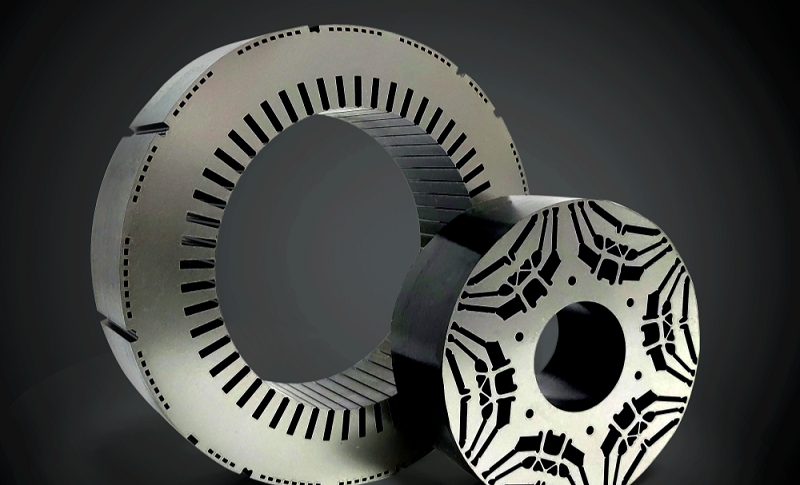

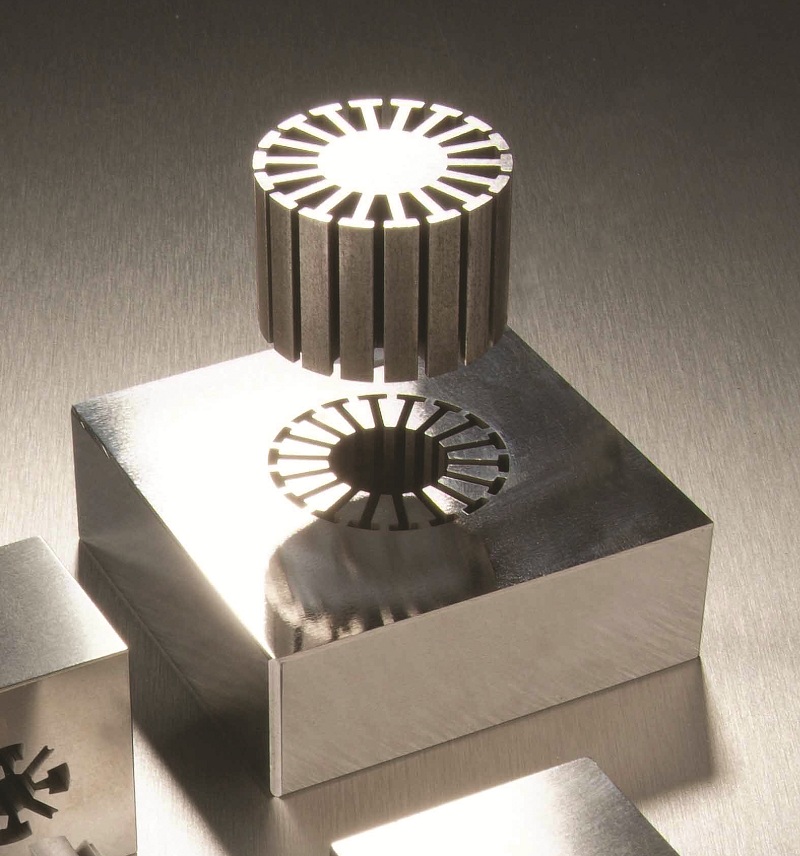

Different from conventional industrial motors, the new energy vehicle drive motor has a narrow working space, and with the high-speed and efficient development of new energy vehicles, its drive motor is more miniaturized, which requires the drive motor to have a high power density and energy conversion efficiency. At the same time, the drive motor is required to have high torque characteristics to achieve accurate torque control, and on the other hand, the drive motor is also required to have high reliability and environmental adaptability to ensure the safety of the vehicle personnel.

Fine grain strengthening is a common strengthening method in iron and steel materials, through the grain boundary pinning dislocation to make the dislocation near the grain boundary to improve the strength of the material, and can improve the plastic toughness of the material, therefore, the general iron and steel materials will be refined grain to obtain high strength and good plastic toughness. The increment of yield strength produced by fine grain strengthening is about 85 MPa, but the corresponding iron loss is higher at this time. The main reason for the increase of iron loss caused by fine grain strengthening is that the grain boundary obstructs the migration of magnetic domain walls.

Dislocation strengthening is one of the most effective strengthening methods in steel materials. Dislocation motion interacts with the defects in the matrix to cause dislocation entanglement and improve the strength of steel materials. When solute atoms enter the steel material matrix, lattice distortion occurs due to the difference in atomic radius between the solute atoms and the matrix, resulting in elastic stress field. The stress field interacts with the nearby dislocation and increases the slip resistance of the dislocation, thus realizing the solid solution strengthening of the steel.

At present, it is generally believed that the precipitation strengthening effect in ferritic steel depends on the competition between the bypass mechanism and the cut mechanism, and the strengthening effect increases with the precipitation phase size, and the precipitation strengthening effect is best when the precipitation phase size reaches a certain critical value.

Although in conventional structural materials, dislocation strengthening and fine crystal strengthening are very effective ways of strengthening, since non-oriented silicon steel is a functional material, it needs to have excellent magnetic properties, which requires that the grains in the finished plate are fully recrystallized and grow. Therefore, the dislocation density and grain size are relatively low in the finished plate of unoriented silicon steel, and the contribution of dislocation strengthening and fine crystal strengthening to the yield strength increment is very limited. They cannot be used as strengthening methods of unoriented silicon steel alone, and often need to work together with other strengthening methods to improve the strength of unoriented silicon steel. The combination of fine crystal strengthening, dislocation strengthening and solid solution strengthening can be considered to achieve the best matching of force and magnetic properties of high-strength non-oriented silicon steel under the joint action of the three strengthening methods.

With the rapid development of new energy vehicles, in order to achieve its high-frequency, efficient and high-speed development needs, higher requirements have been put forward for the performance of non-oriented silicon steel as a key material of rotor iron core, which not only needs to have high magnetic induction and low high-frequency iron loss, but also needs to have high strength. The mechanical properties and magnetic properties of non-oriented silicon steel are difficult to take into account, which is the bottleneck problem in the development of high-strength non-oriented silicon steel for new energy vehicle drive motors. In non-oriented silicon steel, the dislocation density is relatively low and the grain size is relatively large, and the contribution of dislocation strengthening and fine crystal strengthening to the yield strength increment is very limited. They cannot be used as the strengthening methods of non-oriented silicon steel alone. Fine crystal strengthening, dislocation strengthening and solid solution strengthening can be combined. To achieve the best match of force and magnetic properties of high-strength non-oriented silicon steel. Therefore, through the joint action of various strengthening methods or the use of small dispersed nano-coherent precipitates, it is expected to develop high-strength non-oriented silicon steel with high strength and excellent magnetic properties for new energy vehicle drive motor, which is of great significance to achieve the high-quality development of China's new energy automobile industry.

The Role of Alloying Elements in Austenitic Stainless Steel(part 1)

2021-07-26The impact of energy saving and carbon reduction on energy, non-ferrous metals and other industries

2024-06-12Please don't do these four "bad habits" , they will hurt stainless steel pots

2022-08-03How to choose stainless steel screen for room partition in room layout

2021-05-13Are you sure you really can recognize 304 stainless steel material?

2021-10-29Eurofer: Expected EU steel consumption industry output will drop by 12.8% in 2020

2020-11-04