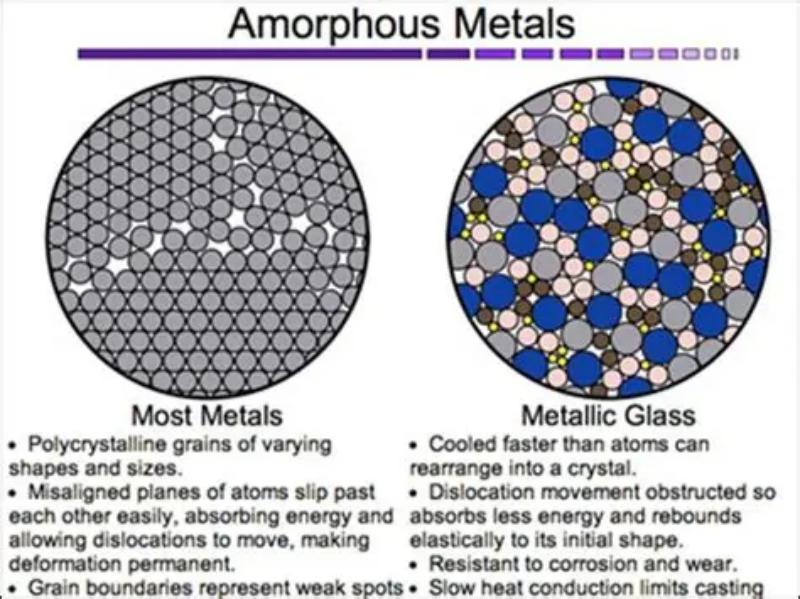

Amorphous alloys, also known as metallic glasses or liquid metals, are novel materials synthesized using modern rapid solidification techniques. Their internal atomic structure is characterized by long-range disorder and short-range order. Due to the unique nature of this internal structure, amorphous alloys combine the excellent mechanical, physical, and chemical properties of both metals and glasses. They exhibit properties such as soft magnetism, superconductivity, low magnetic loss, wear resistance, corrosion resistance, high strength, and high hardness. They have become a major research hotspot in materials science applications and are already widely used in high-tech fields like computers, communications, and power electronics.

01 Material Properties

01 Soft Magnetic Properties

The atomic arrangement in amorphous alloys is long-range disordered, lacking defects like crystal grains, grain boundaries, and dislocations found in crystalline materials. This greatly eliminates the main physical obstacles hindering magnetic domain wall movement. The resistance to magnetic domain wall movement in amorphous alloys is very small, resulting in extremely low coercivity, easy magnetization and demagnetization, a very narrow hysteresis loop, and extremely low hysteresis loss. Due to their structural disorder, amorphous alloys avoid the issue of magnetic anisotropy caused by grain orientation in crystalline materials. This isotropy further reduces the difficulty of magnetization and increases permeability. They can be widely used in power electronics for components like high-frequency transformers, sensors, chokes, and mutual inductors.

02 Corrosion Resistance

As amorphous alloys lack sites prone to localized corrosion, such as grain boundaries, precipitate phase boundaries, and dislocations, and also avoid compositional segregation common in crystalline alloys, they are more uniform in both structure and composition compared to crystalline alloys, resulting in higher corrosion resistance. They can be used to manufacture battery electrodes, submarine cable shielding, corrosion-resistant pipelines, and magnetic separation media.

03 High Elasticity

Due to the long-range disordered atomic arrangement, which eliminates crystal defects like dislocations that are prone to slip, the material undergoes highly reversible, uniform elastic deformation before yielding. Amorphous alloys can achieve an elastic strain of up to 2%, compared to only 0.2% for ordinary metals. This high elasticity gives them unique advantages in fields such as high-performance springs, energy conversion components for sports equipment, precision elastic elements, micro-actuators, and sensors.

04 High Hardness

Although the structure of amorphous alloys is disordered on an atomic scale, it is statistically homogeneous, lacking obvious defect concentration zones or weakening channels like grain boundaries, dislocations, or vacancies. Their atomic arrangement is typically denser than that of crystalline states. When an external load (e.g., an indenter) attempts to press into the material, cooperative atomic rearrangement must occur relatively uniformly across the entire stressed region. This homogeneity enhances the material's overall ability to resist local deformation, manifesting as high hardness. These characteristics make them uniquely valuable in applications like wear-resistant coatings, surface hardening, and precision tools.

02 Material Composition System

The classification of amorphous alloys is primarily based on their base metal elements and alloy system design. Different composition systems exhibit significant differences in thermal stability, mechanical properties, magnetic properties, and corrosion resistance. The main compositional classification systems and their characteristics are as follows:

Fe-based Amorphous Alloys: Fe-based amorphous alloys vary greatly in composition, but a common approach is combining iron (Fe) with metalloid elements to promote amorphization. They offer high saturation magnetization, excellent soft magnetic properties, and relatively low cost. Applied in distribution transformer cores, mid-to-high-frequency magnetic devices. Frequently studied systems include Fe-B, Fe-Si-B, Fe-Si-BP, and Fe-Si-BC.

Co-based Amorphous Alloys: Co-based amorphous alloys possess extremely high permeability and electrical resistivity, reducing high-frequency eddy current losses. Used for high-precision current transformers and high-frequency switching power supply cores. Representative compositions: Co₆₆Fe₄(B,Si)₂₀, Co₇₀Fe₅Mo₅B₂₀. Cr or Mo are often added to enhance corrosion resistance.

Zr-based Amorphous Alloys: Zr-based amorphous alloys have the strongest glass-forming ability, allowing them to be cast into bulk forms. They exhibit ultra-high strength (>1500 MPa) and a large elastic limit (≈2%). Representative compositions: Zr₅₅Al₁₀Ni₅Cu₃₀, Zr₅₂.₅Ti₅Cu₁₇.₉Ni₁₄.₆Al₁₀.

Ti-based Amorphous Alloys: Ti-based amorphous alloys have high specific strength, good corrosion resistance, and low elastic modulus close to that of human bone. Suitable for biomedical implants. Representative compositions: Ti₄₀Zr₂₅Ni₈Cu₉Be₁₈, Ti₅₀Cu₂₃Ni₂₀Sn₇.

Cu-based Amorphous Alloys: Cu-based amorphous alloys are lightweight and possess good electrical conductivity (conductivity ≈ 10³–10⁴ S/m), making them widely applicable in conductive components. Representative compositions: Cu₆₀Zr₃₀Ti₁₀, Cu₄₆Zr₄₂Al₇Y₅, Cu₅₀Hf₄₀Al₁₀.

Pd-based Amorphous Alloys: Pd-based amorphous alloys feature high toughness and corrosion resistance, used for precision optical molds and special corrosion-resistant components. Representative compositions: Pd₄₀Ni₄₀P₂₀, Pd₄₃Cu₂₇Ni₁₀P₂₀.

Mg-based Amorphous Alloys: Mg-based amorphous alloys have very low density, making them the lightest amorphous alloy system. They exhibit high strength, high hardness, corrosion resistance, and biocompatibility. Typically composed of Mg + Transition Metal + Metalloid/Rare Earth. Representative compositions: Mg₆₅Cu₂₅Y₁₀, Mg₆₅Cu₂₅Gd₁₀, Mg₅₄Ag₂₈Y₁₈.

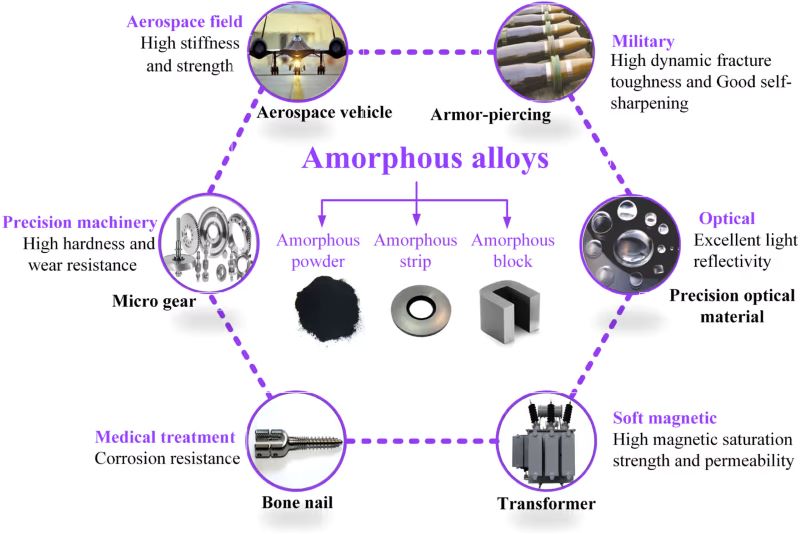

03 Areas of Application

Aerospace:The elastic deformation limit of amorphous alloys can reach up to 2%, and the current maximum elastic limit exceeds 5000 MPa. Among lightweight amorphous alloys, Ti-based ones have an elastic limit exceeding 2000 MPa, unattainable by traditional crystalline and polymer materials. Recently discovered single-phase amorphous alloys exhibit tensile strength greater than 1.5 GPa and fracture toughness up to 200 MPa√m, representing one of the highest fracture toughnesses among materials, achieving a perfect combination of high strength and high toughness. Therefore, amorphous alloys can meet the stringent performance requirements for large deployable structures in spacecraft. Soon after the discovery of bulk amorphous alloys, NASA collaborated with Professor Johnson's group at Caltech to develop high-hardness, high-specific-strength amorphous alloy foam materials. They also utilized the chemical homogeneity of amorphous alloys as solar wind collector materials.

Biomedical: Another important characteristic of amorphous alloys is their biocompatibility, degradability (e.g., Ca-based and Mg-based amorphous alloys), and non-allergenic nature. These properties make them suitable for medical applications, including restorative implants and the manufacture of surgical instruments, such as scalpels, artificial bones, biosensing materials for in vivo electromagnetic stimulation, and artificial teeth. Biodegradable biomaterials offer advantages for implantation as they can avoid secondary surgery for removal and prevent bio-rejection issues associated with permanent implants. Mg-based amorphous alloys, due to their degradability, high strength, and elastic modulus close to bone, have the potential to become the next-generation internal stent material. Consequently, Mg-based amorphous alloys hold great application promise in the field of biodegradable materials. Ti-based and Zr-based amorphous alloys, owing to their high strength, low elastic modulus (close to bone), excellent corrosion resistance, and biocompatibility, are being developed as orthopedic implants for bone screws, bone plates, dental implants, etc. Their surfaces can be easily functionalized to promote osseointegration.

Defense Equipment: Leveraging their unique disordered atomic structure and extreme properties, amorphous alloys demonstrate disruptive application potential in the defense equipment sector, proving particularly irreplaceable in advanced weapon systems, stealth technology, nuclear equipment, and personal protection. Because bulk amorphous alloy materials possess very high dynamic fracture toughness under high-speed loading and exhibit good self-sharpening characteristics when penetrating metals, they are one of the preferred materials for armor-piercing projectile cores. Utilizing the lightweight characteristics of amorphous alloys can lead to smaller artillery volumes, better mobility, and higher projectile velocities.

Electronics & Energy: Electronic devices in computing, networking, communications, and industrial automation extensively use switch-mode power supplies that are light, thin, small, and highly integrated. These power supplies rely on high-frequency electronics, requiring the soft magnetic cores of transformers and inductors to adapt to high-frequency applications. Bulk amorphous alloys, with their high saturation magnetic flux density, high permeability, low loss, and ease of processing, can be directly cast or processed into various complex micro-cores for transformers or inductors used in diverse electronic or communication equipment, showing very broad application prospects and market potential. Distribution transformer cores are a key application for Fe-based amorphous ribbons. Their extremely low iron loss (no-load loss is 60-80% lower than silicon steel sheets) leads to significant electrical energy savings, making them especially suitable for distribution networks with low or fluctuating load rates. Millions of amorphous transformers have been deployed globally.

Sports Equipment

Leveraging their ultra-high strength, large elastic deformation capacity, low damping characteristics, and excellent energy transfer efficiency, amorphous alloys enable groundbreaking applications in the field of high-end sports equipment, significantly enhancing athlete performance.

With an elastic energy storage density of up to 6×10⁶ J/m³, amorphous alloys used in golf club head striking faces allow more kinetic energy to be converted into ball speed upon impact. Utilizing their high elasticity, high strength, and efficient energy transfer properties, they are also widely applied in tennis rackets, ski equipment components, and other related fields.

Yield Strength Vs Tensile Strength

2023-06-26Guangxi Hongwang Electrical Steel Project Officially Breaks Ground

2024-10-24What A Beautiful Hong Wang Garden Factory!

2022-07-29Hongwang's intelligent made,A stunning appearance at the 133rd Canton Fair

2023-04-23The 20 High Rolling mill and BA line put into trial production in Zhaoqing Hongwang

2020-10-30Awards of Hongwang QC’s Necessary Items

2021-06-17