1 Introduction

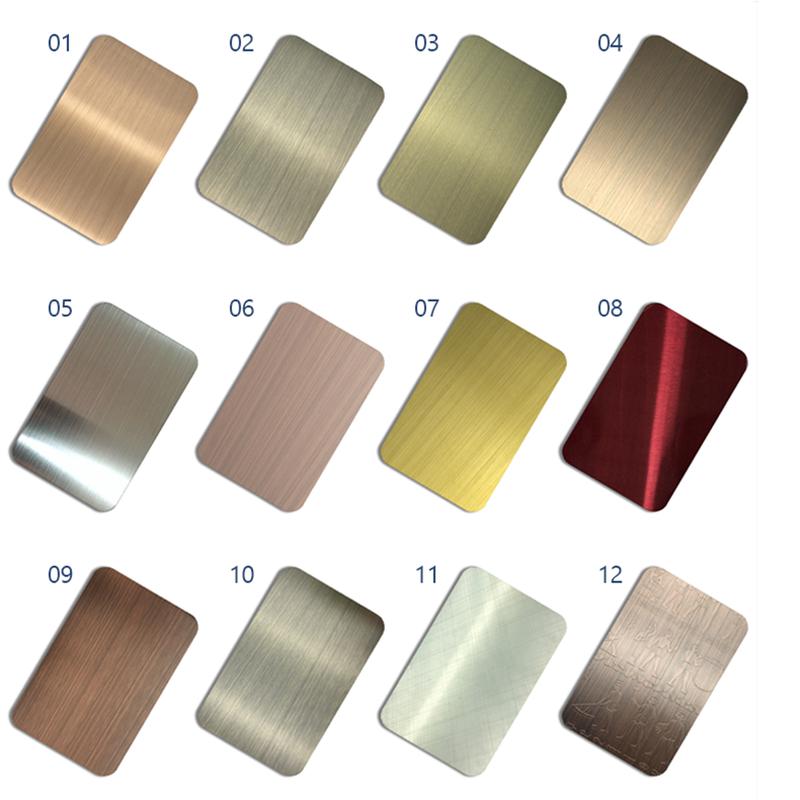

In many stainless steel applications, surface preparation and surface finish are not only important in determining certain functional properties such as corrosion resistance, hardness and hygiene. It is also very important for appearance and aesthetic quality. While almost all stainless steels can be surface treated to produce different colors on the surface, some types of stainless steel produce more colors. The surfaces of austenitic stainless steels, especially 304 and 316, produce most of the colors of the rainbow. Duplex stainless steels and ferritic stainless steels, on the other hand, produce a limited number of colors: for example, the color obtained by electrochemical treatment of ferritic grades is only black-gray.

2. Coating

Like carbon steel, stainless steel can also be painted. But carbon steel is painted for anti-corrosion and other reasons. The purpose of painting stainless steel is different, for example, for safety and convenience reasons. It partially paints stainless steel surfaces to improve the visibility of trucks, railings and other objects. Stainless steel used for panels and roof panels can also be coated with coloured metals such as tin. Coil coating is a special coating that colors stainless steel coils in-line. It is used for applications that require both corrosion resistance and non-reflective surfaces, such as tunnel linings. Also used in the manufacture of furniture, home appliances, refrigerators and metal doors.

3.Electrochemical coloring process

The commonly used method for coloring stainless steel is electrochemical process, also known as electrochemical coloring process. The process, also known as the INCO method, was developed by the International Nickel Corporation (INCO) in 1972. There are many coloring processes currently used, usually immersing stainless steel in a hot chromic sulfuric acid solution or a hot alkaline solution. The stainless steel is then rinsed and the surface hardened using a cathodic treatment. The final color is determined by adjusting the immersion time to control the oxide thickness.

The commonly used method for coloring stainless steel is electrochemical process, also known as electrochemical coloring process. The process, also known as the INCO method, was developed by the International Nickel Corporation (INCO) in 1972. There are many coloring processes currently used, usually immersing stainless steel in a hot chromic sulfuric acid solution or a hot alkaline solution. The stainless steel is then rinsed and the surface hardened using a cathodic treatment. The final color is determined by adjusting the immersion time to control the oxide thickness.

Steel plates are generally electro-chemically colored. The advantage is that no dyes or pigments are used for coloring. the color is super fast and UV is impermeable. In other words, it does not change color in sunlight. The disadvantage is that the color changes when there are scratches and corrosion, and it cannot be repaired.

4. PVD method

In Physical Vapor Deposition (PVD), a color change is created by applying a layer of ceramic to the stainless steel surface to improve durability. Various vacuum deposition processes can be used to deposit the cap film. The coating material is placed in a vacuum and heated to high temperature. When the vaporized form is reached, it is condensed again and then deposited on the desired surface. The technique was first used by Michael Faraday in 1838, but it was not until 1966 that the technique was called physical vapor deposition. Various forms of physical vapor deposition have been developed. A new treatment method developed by the Italian company Steel Color Spa enables the coating of titanium compounds.

The main markets for PVD technology are construction (hotels, train stations, retail stores) and interior decoration (eg door handles, furniture, exhibition stands). This technology is also used in industry, such as in automobile manufacturing, semiconductor wafers, surgical tools, drills and guns to replace chrome plating. Compared to electrochemical coloring, the advantages are more consistent color and better corrosion resistance. Unlike the electrochemical coloring process, the surface color formed by the physical vapor deposition technology does not change with the change of viewing angle.

Stainless Steel Water Pipes: Mainstream Trend for Home Improvement Water Pipes!

2020-11-24SUS304, 304, 06Cr19Ni10 three names of the same kind of steel

2024-07-09304 stainless steel or 316 stainless steel which is better?

2023-10-17The role of stainless steel screens in different decorative spaces

2021-06-29Mirror Stainless Steel Grinding and Polishing

2021-08-03Common treatment processes for stainless steel surfaces

2024-05-10