In the steel jungle of the electrical era, there is a special material that supports the power lifeline of modern civilization. It appears ordinary but is extremely valuable, and is known as the "steel aristocracy". From the lights of countless homes to the speed of high-speed trains, all embody the wisdom of this material - this is silicon steel, the indispensable "soft gold" of modern industry.

Electrical Steel is an ultra-low carbon alloy steel with a silicon content ranging from 0.5% to 4.5%. This seemingly ordinary sheet material is actually the core material of electrical equipment. Its unique magnetic properties make it the optimal choice for manufacturing transformer cores and motor rotors. For every 1% increase in silicon content, the resistivity increases by approximately four times, effectively reducing the eddy current losses generated during equipment operation.

In ultra-high voltage substations, the laminated thickness of silicon steel sheets is precisely controlled between 0.23-0.35mm, which is equivalent to the thickness of 5 sheets of A4 paper. The (110) [001] texture formed through a special rolling process achieves a magnetic induction strength of 1.9T or higher, which means that it can carry a larger magnetic flux under the same volume. It is precisely the precise control of this microstructure that supports over 98% of the transmission efficiency of the power grid.

The production of silicon steel can be regarded as the "crown jewel" of the metallurgical industry, which involves 18 key processes including steelmaking, hot rolling, normalizing, and cold rolling. The decarburization annealing process needs to be carried out in a hydrogen nitrogen mixed atmosphere at 800 ℃ for 5 minutes to control the carbon content below 30ppm. More precise HiB steel (high magnetic orientation silicon steel) also requires laser scoring treatment to form micrometer level grooves on the surface, reducing the magnetic domain width to within 2mm.

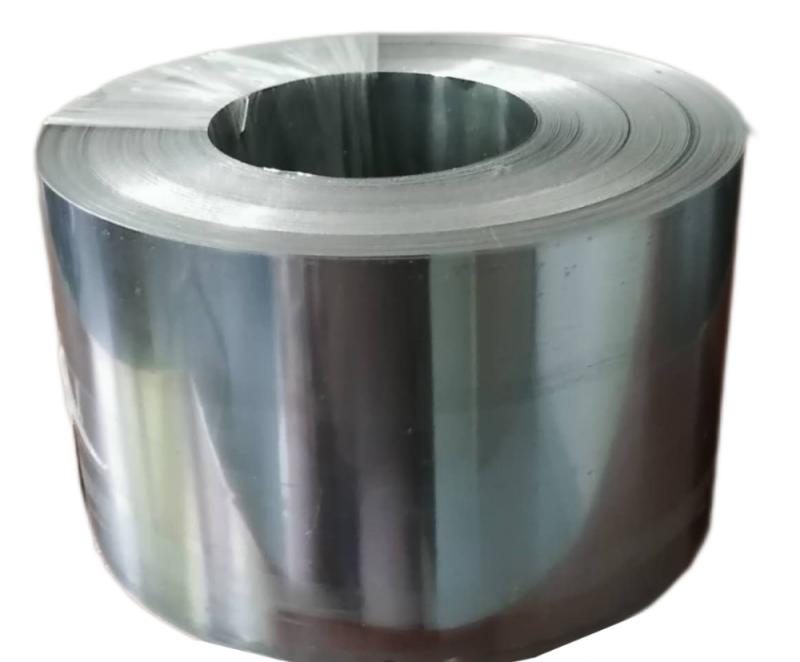

The shape control of the cold rolling process can be called art. The six high rolling mill needs to roll the 3mm thick hot-rolled plate to 0.3mm with a thickness deviation of no more than ± 3 μ m. The continuous decarburization annealing line using electromagnetic induction heating can uniformly heat the steel strip to 830 ℃ at a speed of 20m/min, forming a perfect secondary recrystallization structure. The stable control of this process directly determines the magnetic performance level of the product.

In the field of new energy vehicles, silicon steel is experiencing explosive demand. The non oriented silicon steel used for driving motors requires a magnetic induction B50 of at least 1.7T and an iron loss P1.5/50 of less than 4.0W/kg. In the permanent magnet synchronous motor of Tesla Model 3, the stator core is made of 0.25mm ultra-thin silicon steel sheets laminated, which makes the motor efficiency exceed 97% and the driving range increase by 8%. The upgrade of wind power equipment highlights the value of silicon steel. The doubly fed generator of a 5MW offshore wind turbine requires the use of high-grade silicon steel with a thickness of 0.2mm, and its magnetostriction coefficient needs to be controlled below 3ppm to ensure stable operation under strong wind loads.

In the future, silicon steel will develop towards ultra-thin technology, and ultra-thin strip steel with a thickness of 0.1mm has entered the experimental stage. This material can make the speed of high-speed motors exceed 50000rpm, meeting the requirements of aviation electric propulsion systems. At the same time, the composite application of amorphous alloys and silicon steel is emerging. Through magnetic domain refinement technology, it is expected to further reduce the no-load loss of transformers by 30%, providing key technical support for the "dual carbon" goal.

South China Stainless Steel Sheet Stereo Intelligent Warehouse Online!

2020-09-10Yield Strength Vs Tensile Strength

2023-06-26Hongwang Investment Group ranks 485th among 2020 Top 500 Chinese Enterprises

2020-10-10Silicon steel power, wisdom leads the future

2024-03-21HWHG Ranks 228th in 2024 China Top 500 Manufacturing Enterprises

2024-10-24Hongwang Hi-tech | Intelligent Production of Single Continuous Rose Gold

2021-05-14