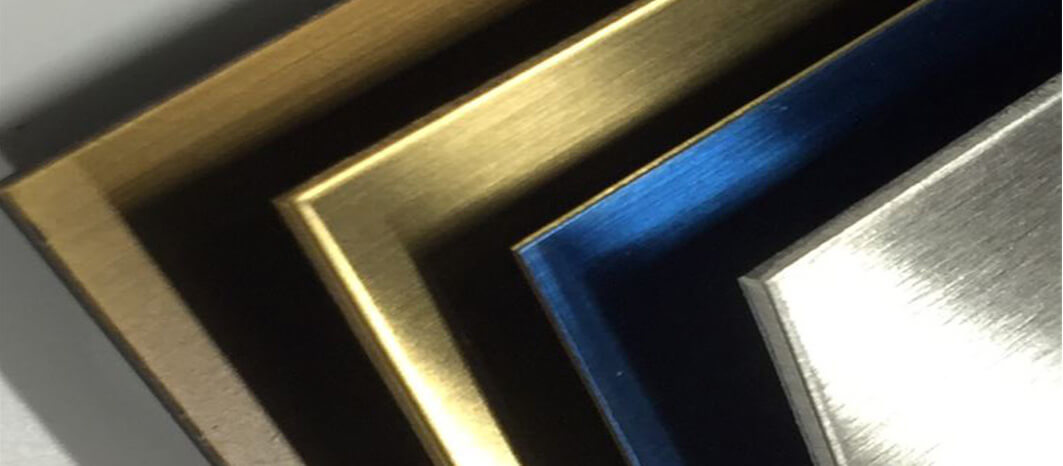

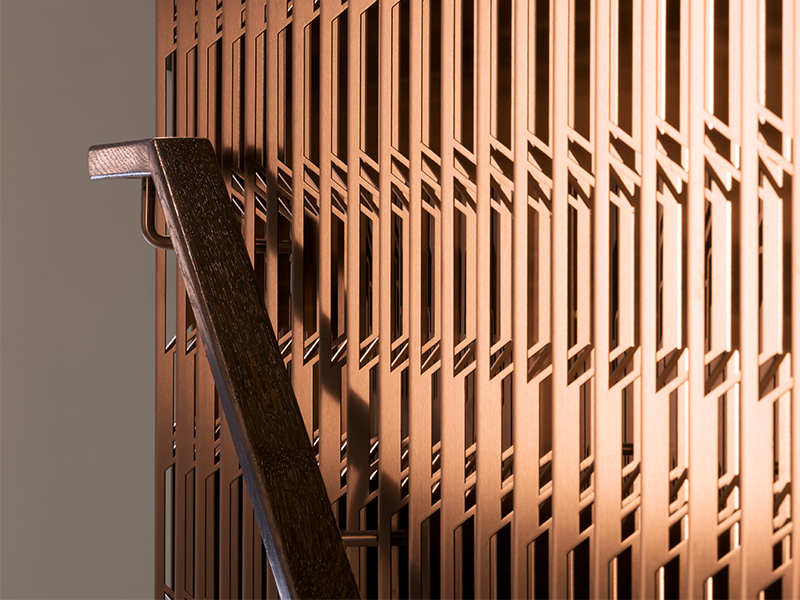

For stainless steel plate, is your first impression that there is only one color---silver? For example, stainless steel bowls, or the stainless steel which be used in heavy industry. But now stainless steel can be seen everywhere in everyone's life, such as the bronze stainless steel hotel doors, the rose gold stainless steel screen in home decoration, and the landscape basin in some courtyards. How to make stainless steel so colorful? Here are some of the most common ways of colored stainless steel color sheets.

1. High Temperature Oxidation Coloring Method:

In a specific molten salt,,the stainless steel sheets with original surface will be immersed the workpiece at a certain process range to form a certain thickness of oxide film,then the surface will show a variety of different colors.

2. Ion Deposition Oxide Coloring Method:

This method is to put stainless steel products or stainless steel sheets in vacuum coating machine for evaporation coloring. This method is suitable for mass processing, such as gold mobile phones, watch straps and so on.

3. Chemical Oxidation Coloring:

The color of film formed by chemical oxidation in specific solution includes dichromate method, mixed sodium salt method, vulcanization method, acid oxidation method and alkaline oxidation method.

4. There is also a more complex stainless steel coloring process called gas-phase column solution (gas-phase decomposition coloring method), but it is rarely used in industry, so it will not be introduced here.

Through so many methods to color the stainless steel plate and stainless steel coil, with the harmony of color, the originally cold stainless steel also has a warm and soft feeling, and there are more ways to use it.

Difference between Medical stainless steel and Food-grade stainless steel

2023-01-05Stainless Steel Development in Pharmaceutical industry

2022-08-15Demand for oriented electrical steel set a new record

2023-12-02Technological Innovation and Application of Transformer Cores in the Context of Smart Grids

2024-12-18The Role of Important Alloying Elements of Austenitic Stainless Steel (Part2)

2021-07-27What are the different options for stainless steel?

2021-02-24