Pig iron and steel are mixtures, different mechanical strength, different castability, but the most important difference is the carbon content. The steel system is made of pig iron, has high mechanical strength and toughness, and has special properties such as heat resistance, corrosion resistance and wear resistance. Generally, the carbon content of less than 0.0218% is called wrought iron or pure iron, the content of 0.0218-2.11% is called steel, and the content of more than 2% is called pig iron. Wrought iron is soft, good plasticity, easy deformation, low strength and hardness, not widely used; Pig iron contains a lot of carbon, is hard and brittle, and has little plasticity. Iron is extremely rich in nature, accounting for 5% of the earth's crust element content, ranking fourth in the earth's material. Iron is very active and easily combines with other substances. It is customary to say that iron and steel is a general term for steel and iron.

There is a difference between steel and iron, the so-called steel, mainly composed of two elements, that is, iron and carbon, generally carbon and element iron to form a compound, called iron-carbon alloy. The amount of carbon content has a great impact on the properties of steel, and the increase of carbon content to a certain extent will cause qualitative changes. A substance made up of iron atoms is called pure iron, and pure iron has few impurities. Carbon content is the main criterion to distinguish steel. The carbon content of pig iron is greater than 2.0%; The carbon content of steel is less than 2.0%. Pig iron has a high carbon content, is hard and brittle, and has little plasticity. Steel not only has good plasticity, but also steel products with high strength, good toughness, high temperature resistance, corrosion resistance, easy processing, impact resistance, easy to refine and other excellent physical and chemical application properties, so it is widely used.

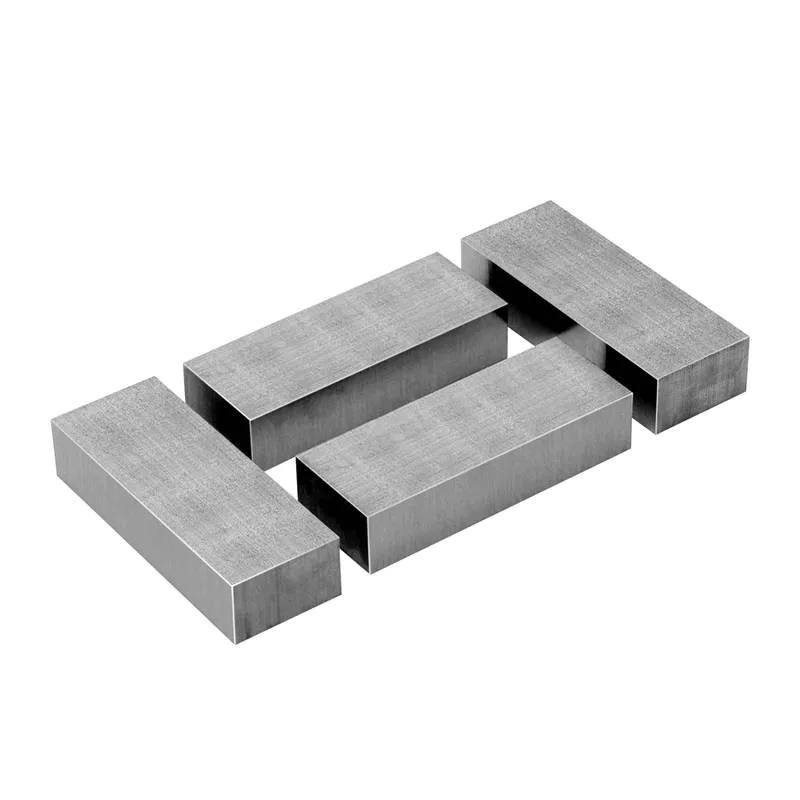

Cast iron is made of iron ore by grinding, grinding into powder, into the smelting furnace by high temperature calcination into liquid (commonly known as hot metal) and then poured into a special mold after cooling into iron ingot also called billet or pig iron, the main components of cast iron are: alloy composed of iron, carbon and silicon.

Steel is made of billet also called cast iron or pig iron after high temperature calcination with heavy machinery after forging into steel (the so-called hundred steel is this meaning), the main components of steel or iron, carbon and silicon composed of alloy is only according to the steel in the use of different fields of its alloy body carbon and silicon content is different, Steel in the process of forging carbon and silicon precipitation to reduce its content to meet the needs of different fields of use.

Stainless Steel Water Pipes: Mainstream Trend for Home Improvement Water Pipes!

2020-11-24Amorphous Alloys: Multidimensional Performance Analysis, Composition Systems, and Cutting-Edge Applications

2025-11-17Punching technical requirements for iron core

2024-01-04Nickel Cost Rises,Stainless Steel Producers’ Profit margin extruded

2020-09-29Stainless steel surface treatment process- Brushed

2020-11-10What are the common uses of stainless steel coils?

2021-02-10