|

Product Name |

Non-oriented Silicon Steel |

|

Origin |

Hongwang,China |

|

Standard |

GB |

|

Thickness |

0.35-0.5mm or as required |

|

Length |

Customized |

|

Width |

≤1200mm |

|

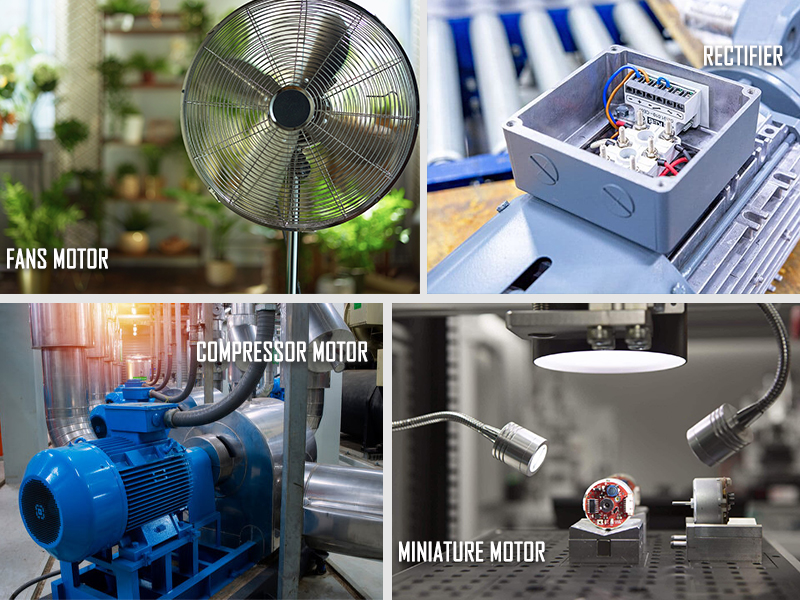

Application |

Iron cores for electric motors/generators/transformers |

|

Certificate |

CE,ISO9001 |

|

Processing |

Welding, Punching, Cutting, Bending, Decoiling

|

|

Sample |

Available |

|

Delivery |

7~25 days |

|

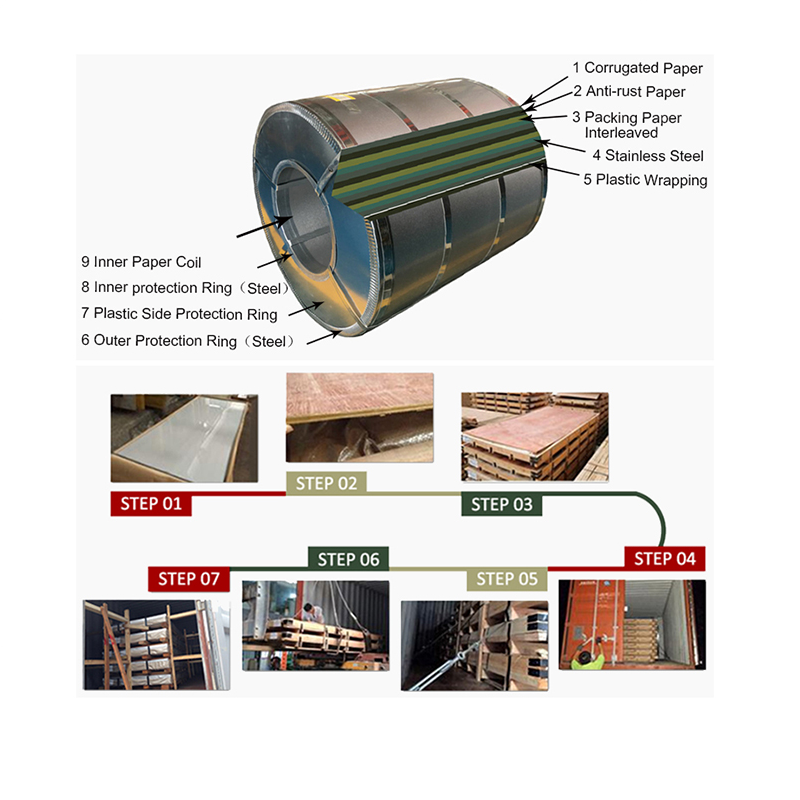

Packing |

Wooden pallet |

|

Moq |

2 MT |

|

Business code |

Factory directly sell |

Silicon steel is an extremely low-carbon ferrosilicon soft magnetic alloy indispensable for electric power, electronics, and military industries. It is also the metal functional material with the largest output, and its output accounts for about 1% of the world's steel output.

It is a ferrosilicon alloy containing 0.8%-4.8% silicon. After hot and cold rolling, it becomes a silicon steel sheet with a thickness of less than 1mm.

Adding silicon can increase the resistivity and maximum permeability of iron, reduce the coercive force, core loss (iron loss) and magnetic aging, and is mainly used as the iron core of various motors, generators and transformers.

Non-oriented silicon steel is a ferrosilicon alloy with very low carbon content. In the steel plate after deformation and annealing, the grains are distributed in random orientation.

| Grade |

Nominal thickness

mm

|

Theoretical density

Wg/dm3

|

The maximum iron loss

W/kg

|

The minimum magnetic induction

T

|

The minimum number of bends |

The minimum stacking factor

%

|

||

| 50Hz | ||||||||

| B5000 | ||||||||

| 50HW600 | 0.5 | 7.75 | 4.20 | 1.67 | 12 | 97.5 | ||

| 50HW800 | 7.78 | 5.80 | 1.70 | 15 | ||||

| 50HW1000 | 7.85 | 7.50 | 1.74 | 15 | ||||

| Grade |

Nominal thickness

mm

|

Theoretical density

Wg/dm3

|

Iron loss

W/kg

|

Magnetic induction

T

|

||||

| 50Hz | 60Hz | |||||||

| 1.0T | 1.5T | 1.0T | 1.5T | 2500A/m | 5000A/m | |||

| 50HW600 | 0.5 | 7.75 | 1.71 | 3.79 | 2.16 | 4.82 | 1.64 | 1.72 |

| 50HW800 | 7.80 | 2.10 | 4.67 | 2.41 | 5.49 | 1.66 | 1.74 | |

| 50HW1000 | 7.85 | 2.44 | 5.32 | 3.09 | 6.85 | 1.68 | 1.76 | |

| Grade |

Yield strength

N/mm2

|

Tensile strength Rm

N/mm2

|

Elongation

%

|

HV5 |

Stacking factor

%

|

|||

| L | C | L | C | L | C | |||

| 50HW600 | 280 | 295 | 410 | 425 | 40 | 42 | 130 | 98.5 |

| 50HW800 | 255 | 265 | 380 | 390 | 45 | 46 | 105 | 98.5 |

| 50HW1000 | 230 | 240 | 350 | 360 | 50 | 50 | 100 | 98.5 |

| Item Specification | Coil Weight | Standard |

|

0.35-0.5mm or as required |

3-5 MT or according to requirement | GB/HONGWANG STANDARD |

![]() Company Introduction:

Company Introduction:

Wuxi Hongwang Stainless Steel Co., Ltd. was founded in 2016, is the professional silicon/electrical steel import and export trading platform of Hongwang Group integrating international trade, storage, processing and after-sales service. It also plays an important role for the international marketing of high quality products manufactured by the group's major manufacturing bases. Wuxi Hongwang establishes a professional international trade service team, equipped with sufficient storage and processing services, to provide professional stainless steel import and export trade services for the majority of oversea customers with fast response, reliable quality, and good after-sales service.

![]() APPLICATION:

APPLICATION:

OUR SERVICE:

1.Professional work.

2.OEM&ODM, also provide customized service.

3.Offer for your unique design and some our current model.

4.Protection of your sales area, ideas of design and all your private information.

5.Provide strict quality check for each part , each process before export.

6.Provide complete post-sale service, including installation , technical guide.

We have high-tech equipment to processing stainless coils and sheets/plates with skilled workers.

1.Cut to length

2.Despoiling and slitting

3.Grinding and brushing

4.Film protection

5.Plasma and water jet cutting

6.Embossing

7.Mirror or others finish

FAQ

Q1.Can you supply the relevant documentation?

A1.Yes, we can provide most documentation such as Inspection Certificate/Mill Test Certificate, Insurance, Certificate of Origin, SASO, Form E, and other export documents what required.

Q2.Are you a manufacturer?

A2.Yes, hongwang are a famous manufacturers in Chinese market. We have our own silicon sreel mills and our own trading companies. All our goods are dispatched directly from Hongwang mill. I believe we will be the most suitable supplier for you.

Q3.How can you ensure the quality of your product?

A3.All products have to go through three checks in the whole manufacturing process,it includes production,cutting sheets and the packing.

HONGWANG SHIPPING PACKING: