Electrical alloy steel with silicon content of 1.0 ~ 4.5% and carbon content of less than 0.08% is called electrical steel. It has the characteristics of high permeability, low coercivity and large resistivity, so the hysteresis loss and eddy current loss are small. It is mainly used as magnetic material in motors, transformers, electrical appliances and electrical instruments. In order to meet the needs of punching and shearing processing when manufacturing electrical appliances, it is also required to have a certain plasticity. In order to improve the magnetic susceptibility and reduce the hysteresis loss, the harmful impurity content is required to be as low as possible, and the plate shape is required to be flat and the surface quality is good.

Electrical steel core loss (referred to as iron loss) and magnetic induction strength (referred to as magnetic induction) as the product magnetic guarantee value. The low loss of electrical steel can save a lot of electricity, extend the operating time of motors and transformers and simplify the cooling system. The power loss caused by electrical steel damage accounts for 2.5% ~ 4.5% of the annual power generation, of which the transformer iron loss accounts for about 50%, 1 ~ 100kW small motor accounts for about 30%, and the fluorescent lamp ballast accounts for about 15%.

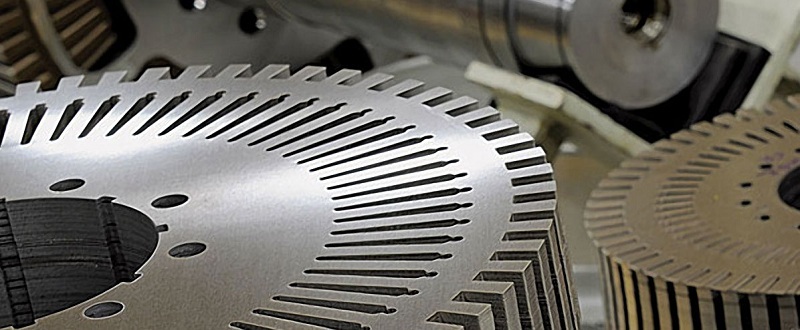

The electrical steel has high magnetic induction, and the excitation current of the iron core is reduced, which also saves energy. The high magnetic induction of electrical steel can make the design of the maximum magnetic induction (Bm) high, the core size is small, light weight, saving electrical steel, wires, insulation materials and structural materials, both the motor and transformer loss and manufacturing costs are reduced, but also easy to assemble and transport. The motor, which consists of a toothed circular punch forming an iron core, works in a running state. The electrical steel plate is required to be magnetic isotropic and made of non-oriented electrical steel. Transformers consisting of strips stacked into an iron core or strips wound into an iron core operate at rest and are made of cold-rolled oriented electrical steel with high magnetic anisotropy. In addition, the electrical steel is required to have good punching property, smooth surface and uniform thickness, good insulation film and small magnetic aging.

The requirements for the performance of electrical steel are mainly five aspects, the first iron loss is low, which is the most important indicator of the quality of electrical steel sheet. Countries are divided according to the iron loss value, the lower the iron loss, the higher the brand. The second is the high magnetic induction intensity (magnetic induction) under the strong magnetic field, which reduces the volume and weight of the iron core of the motor and transformer, saving electrical steel sheet, copper wire and insulating materials. Third, the surface is smooth, flat and uniform thickness, which can improve the filling coefficient of the iron core. The fourth is good punching, which is more important for the manufacture of micro and small motors.

Common 304 stainless steel sheet types

2020-12-24How are metal composites "compounded" together?

2023-11-16QN1803 stainless steel grow against the trend,or fully replace 304 ?

2022-10-20Main Uses & Application Fields of Stainless Steel Water Tank

2022-08-01The distinction between hot rolled steel and cold rolled steel

2023-08-30Unlocking New Trends in Amorphous Semiconductor Development with Intelligent Sensing: The 29th South Australia Science Conference Held

2026-01-27