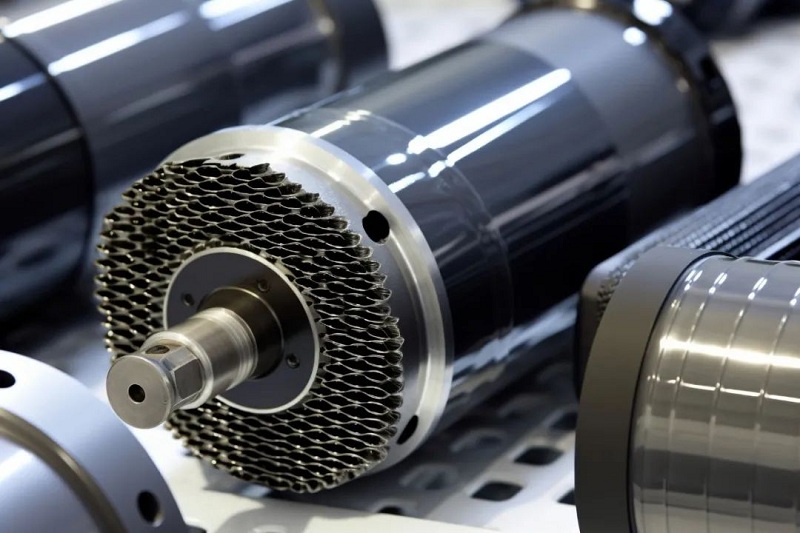

With the gradual replacement of fossil fuels, the importance of electric motors in major engineering fields such as automobiles and industries is becoming increasingly prominent. Several key components of the motor, such as the rotor and the stator core, are made of electrical steel, electrical steel's excellent magnetic properties and processing properties are beneficial to the high efficiency of the motor.

The iron core is generally made by cutting, laminating and connecting electrical steel plates. At present, the most common process for cutting is to press the sheet metal. Stamping dies often require a high level of initial investment, but once installed is a relatively quick and one-shot method of forming. Laser cutting also requires a high initial investment, is a very time-consuming process, but has excellent flexibility, and is therefore the preferred method for small batch or single molding production. While other cutting processes exist, such as abrasive water jet and wire-cut discharge machining, these processes are typically used for specific applications rather than large-scale manufacturing.

In laser cutting, the multi-substrate cutting operation, that is, stacking several sheets and then cutting at the same time, can significantly improve the efficiency of the operation, but it is unclear how the use of this method will affect the quality of the parts produced. Stamping is a mechanical process, but laser cutting is a thermal strength process, so the effect of laser cutting is slightly different from stamping. Changes in the microstructure of the material may have a potential negative impact on the magnetic properties of the material, and effects such as crystal texture and grain size changes may lead to a decrease in the performance of electrical steel. To this end, researchers such as Nathan Dodd from the University of Sheffield in the United Kingdom have deeply explored the influence of steel plate edge quality and magnetic properties of electrical steel plates in the process of multi-substrate cutting.

They perform multi-substrate cutting by stacking 0.35mm thick M250-35A grade electrical steel into 7 layers. The lamination is held together with 4 mm diameter bolts to reduce the impact of part movement during cutting. The laser cutting trials were carried out using a 3kW Trumpf laser located at the University of Sheffield's Advanced Manufacturing Research Centre. By measuring the magnetic properties of the electrical steel plate with Epstein square ring after cutting, and observing the quality of the cutting edge with scanning electron microscope (SEM), the following conclusions are drawn:

Laser cutting can cut multiple layers of steel at the same time to improve the production efficiency of core manufacturing, but it will also cause the deterioration of the magnetic properties of electrical steel plates. Compared with the stamping process, although laser cutting can achieve better edge quality, but in the larger wood stack cutting, as the edge material melts and flows downward, the laminated steel plates will stick to each other, although in most cases can be manually separated, but after the thickness of the stack increases to 23 layers, the bonding strength between the layers will increase a lot. It is therefore much more difficult to separate after cutting. Another problem is that the cut steel sheet can be slightly bent or warped. This is due to the residual stress created when the material at the cut edge is melted by the laser and cured again, during which the steel plate shrinks.

As with other cutting processes, laser cutting electrical steel also leads to a deterioration of magnetic properties, which is slightly higher than that of stamping. In experiments, the loss deterioration caused by stamped stators is usually between 17% and 28%, while the loss deterioration caused by laser cutting is about 26% to 37%. With the further development of research work, such as the study of the process optimization of different laser cutting equipment, it is possible to achieve a higher level of laser cutting quality, and may also exceed the current level of stamping.

More extensive research on laser cutting conditions and parameters is recommended. Such as multi-cut, that is, the laser is deflected many times around the incision to remove the material more gradually, which will reduce the processing strength and reduce the deterioration of the magnetic properties of the steel plate. Although this will affect the processing efficiency, because the laser movement is very fast, this part of the time can be ignored compared to the cutting material time.

Laser cutting is still an interesting alternative to stamping, from the point of view of cost, time and quality, "multi-substrate cutting operation" has the potential to become a more efficient production method, but the bonding effect between steel plates, the warping of steel plates and other aspects still need to be further optimized in order to produce iron core products with higher magnetic properties. By then, multi-substrate laser cutting is not only a viable alternative method, but also the preferred alternative method for stamping.

The difference between 304 stainless steel and 316 stainless steel

2023-09-23Laser cutting technology on the iron core of new energy motor

2023-09-15Buying Stainless Steel Cookware? Read this First(1)

2023-07-17The Process and Classification of Silicon Steel

2025-10-16What are the common uses of stainless steel coils?

2021-02-10Why is the motor "iron" core?

2023-09-14