We analyzes the appearance and causes of folding and printing defects in stainless steel cold-rolled strip, and puts forward corresponding solutions on this basis. It has a practical guiding effect on improving the yield of stainless steel cold-rolled strip and expanding the application field.

Stainless Steel Strip Introduction

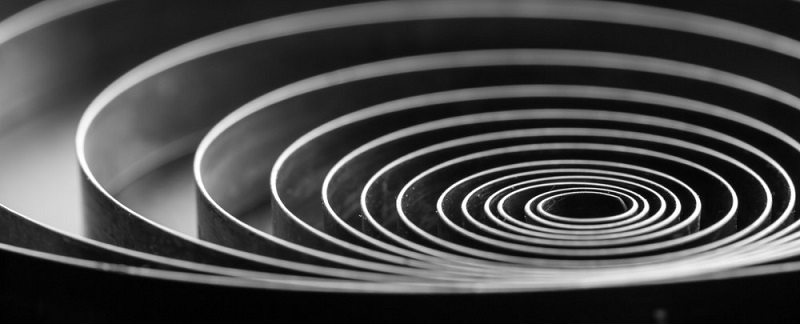

Stainless steel cold-rolled strip coiling and printing is a kind of strip steel that is partially rolled along the length of the reel body when the strip is coiled. During the strip coiling process, the lateral bulge of the steel strip occurs periodically at this part. Generally, periodic folding and printing defects with a certain length are formed at the strip coiling head, sometimes as long as hundreds of meters. These folds and marks formed on the surface of the strip are difficult to eliminate even after being flattened and straightened, which directly affects the application of products in high-end fields such as frosted boards, hairline boards and decorative boards.

Lamination of transformer manufacturing process

2024-07-22Influence of core stress on performance of permanent magnet motor

2024-04-07The role of stainless steel in offshore applications

2024-04-18What are the advantages of stainless steel flower pots?

2022-08-16What is the difference between 200, 300, 400 series stainless steel?

2024-05-11What should we pay attention to when buying a transformer

2023-11-03