Silicon steel, also known as electrical steel, is an essential foundational material indispensable to the modern electrical engineering industry. It is produced by adding an appropriate amount of silicon (typically 1.0%~4.5%) to ordinary carbon steel and then undergoing a series of specialized processes such as cold rolling, annealing, and coating. The addition of silicon significantly alters the electromagnetic properties of the steel, endowing it with high magnetic permeability, low iron loss, and excellent resistivity.

Its most significant advantage lies in its stable magnetic performance and extremely low loss under alternating magnetic fields, which can effectively reduce the loss of electrical energy in the electromagnetic conversion process and greatly improve the operating efficiency of the equipment. Therefore, silicon steel is known as the "heart material" of motors and transformers.

At present, silicon steel is widely used in traditional electrical fields such as motors, transformers, household appliances, and communication equipment. It also plays a key role in emerging industries such as new energy vehicle drive motors, wind power generation, photovoltaic inverters, and smart grids. With the global energy structure transformation and the introduction of energy-saving and emission reduction targets, the importance of silicon steel has become increasingly prominent. Its performance level is directly related to the energy efficiency, stability, and green development of the equipment manufacturing industry.

According to the different grain orientations, silicon steel is divided into two categories:

Oriented silicon steel (CRGO): The grain arrangement is highly oriented, and the magnetic properties are optimal in the rolling direction.

Non oriented silicon steel (CRNGO): The grains are randomly distributed, and the magnetic properties are relatively uniform in all directions.

Performance and Characteristics of CRGO:

The grains of oriented silicon steel are highly oriented in the rolling direction, and its magnetic properties are extremely excellent in a single direction.

Low rail loss: Energy loss is extremely low in alternating magnetic fields, which can significantly improve equipment operating efficiency.

High magnetic permeability: Under the same magnetic field conditions, the magnetic induction intensity is higher.

Excellent insulation performance: using inorganic coating to effectively reduce eddy current losses.

Therefore, it is the preferred material for manufacturing efficient transformers and large power equipment.

Manufacturing process flow:

Melting → Hot rolling → Cold rolling → Primary annealing → Secondary cold rolling → High temperature annealing → Surface coating (inorganic coating) → Finished coil

This process ensures the orientation of the grains and excellent magnetic properties.

Application field:

Various types of power transformers (distribution transformers, power transformers), large transformers, reactors, and new energy grid equipment.

Value realization: Oriented silicon steel can significantly reduce electrical energy loss and minimize energy waste during power transmission, making it a key material for achieving efficient and energy-saving power grid construction.

Performance and Characteristics of CRNGO:

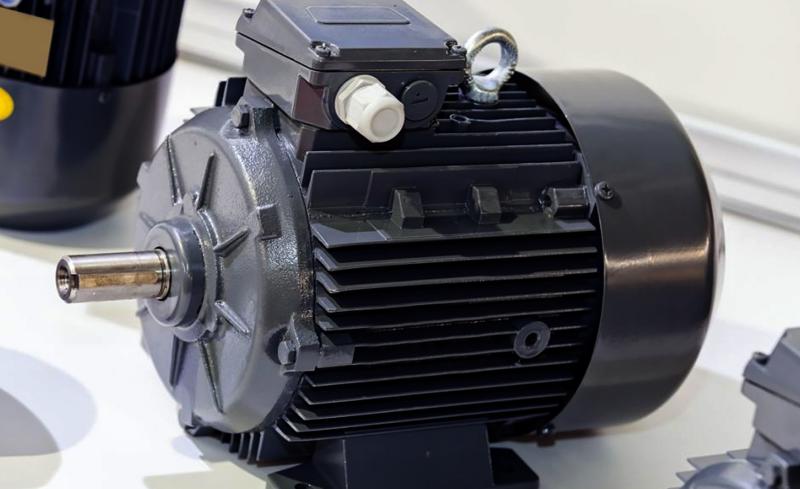

The grain distribution of non oriented silicon steel is random, and the magnetic properties in all directions are uniform. It has good processing performance and stable mechanical strength, and is suitable for working in a rotating magnetic field environment.

Isotropic: Consistent magnetic properties in all directions, suitable for rotating equipment such as motors.

Excellent punching performance: able to withstand high-speed stamping and complex shape processing.

Stable efficiency: ensuring low noise and low energy consumption during the operation of the motor.

Manufacturing process flow:

Melting → Hot rolling → Cold rolling → Continuous annealing → Semi organic coating → Finished coil

This process ensures good isotropy and low levels of iron loss.

Application field:

Various types of electric motors (industrial motors, traction motors), generators and compressors, household appliance motors, new energy vehicle drive motors, wind power generation equipment.

Value realization: Non oriented silicon steel is widely used in the rotating machinery and new energy vehicle industries, and is a core material for promoting green travel and the development of new energy.

LME nickel price hits 5-week high,

2023-06-20Fujian Hongwang Happy Hour in Food Fair

2020-09-102022,Hongwang Group Vertical Furnace Production line 1st Stainless Steel Coil officially Showing up!

2022-03-23Zhaoqing Hongwang was Approved to set up Guangdong Doctor Workstation

2020-09-10Silicon steel power, wisdom leads the future

2024-03-21High EQ Person in Hongwang

2021-06-17