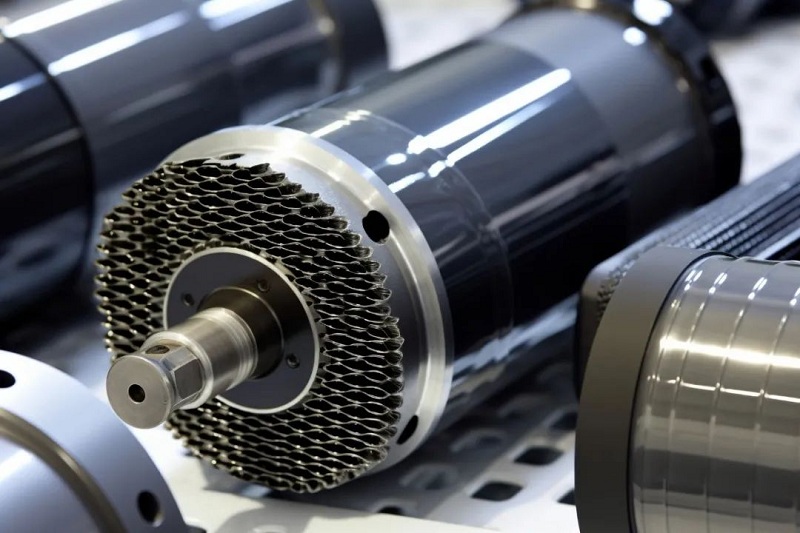

In the face of global energy crisis, the energy efficiency of electrical equipment has been widely concerned. Statistics show that motors usually account for about 2/3 of industrial power consumption. Stator and rotor cores are usually made of unoriented electrical steel because they have good magnetic isotropy. Laser cutting is widely used in the processing of electrical steel, with the advantages of non-contact, fast cutting speed and so on. However, a large number of studies have shown that the stress caused by laser cutting on the electrical steel plate will significantly affect the magnetic properties of the edge, resulting in an increase in core loss, so analyzing the degree and mechanism of magnetic degradation after laser cutting is crucial to improve the efficiency of electrical equipment.

In order to accurately predict the core loss of the motor, it is very important to analyze the deterioration degree and mechanism of non-oriented steel plate caused by laser cutting. Zhang Changgeng et al. from Hebei University of Technology calculated and compared the deterioration zone of non-oriented electrical steel plate caused by laser cutting through a local magnetic characteristics test system. Then, based on the magnetic domain observation technique, the edge domain pattern and its variation rule under magnetic field excitation are studied.

The researchers measured the local magnetic properties of unoriented steel 35WW250 at different locations under alternating sinusoidal excitation and assessed the degree of degradation based on core loss from a macroscopic perspective. According to the changes of hysteresis loops before and after laser cutting, the magnetic properties of the sample edge have been degraded by laser cutting, and the closer to the cutting edge, the worse the magnetic properties of the sample. The magnetic properties of the area within 18 mm of the edge decreased significantly. Among them, the deterioration of magnetic properties is most obvious in the area less than 4 mm from the edge.

From the point of view of the core loss of non-oriented steel electrical steel at different frequencies and positions, laser cutting leads to a significant increase in edge loss, especially the hysteresis loss and dynamic loss are significantly increased, and the core loss is positively correlated with the operating frequency. This is because the hysteresis loss of ferromagnetic materials comes from the motion of magnetic domains, and the laser cutting process increases the resistance of magnetic domain motion, thus increasing the hysteresis loss. The residual stress component perpendicular to the edge also increases the hysteresis loss. The dynamic loss is composed of classical eddy current loss and excess loss caused by uneven distribution of magnetic domain patterns. An increase in the field width may also lead to an increase in dynamic loss.

In addition, the researchers studied the observed magnetic domain patterns at the edge and the evolution process under magnetic excitation from a microscopic perspective. The laser cutting process results in significant changes in the magnetic domain pattern at different locations. Magneto-optical observation and local magnetic measurement verify the effectiveness of the analytical method, which is of great significance to the evaluation and improvement of silicon steel processing technology.

Where is the application field of 316L stainless steel pipe drawing technology?

2021-03-10Types of stainless steel plates

2021-04-29Discussion on grounding reasons of Transformer Iron Core

2023-08-23Current situation and future development trend of Chinese automotive motor iron core market

2024-01-18Stainless Steel Water Pipe Market Scale Reveals: Unlimited Potential Investment Opportunities

2025-10-27Hongwang’s exclusive brushing process technology

2023-02-09