The surface treatment process of stainless steel plate is divided into many kinds, such as sandblasting, passivation, electroplating, pickling, painting, oil degreasing and rust removal, anodizing and so on. But the more common basic three, they are passivation, pickling and degreasing oil.

Stainless steel passivation, the surface of the conditions using this surface treatment process cannot contain iron. For example, the stainless steel particles on the surface of cast iron, low carbon steel, medium carbon steel or low alloy steel will cause the "free" iron on the surface of the stainless steel to pitting with the stainless steel. This problem is very serious, so passivation is only suitable for the treatment of stainless steel and stainless iron. The main purpose of stainless steel passivation is to avoid oxidation and corrosion on the surface of the stainless steel plate.

Stainless steel pickling, the purpose of stainless steel pickling treatment is to remove the oxidation of the surface of stainless steel after high temperature welding, heat treatment or hot working. In addition, it can remove red rust corroded steel, iron or steel particles. It should be noted that if the acid on the surface of the stainless steel plate is not cleaned after pickling, the surface of the stainless steel plate will soon be corroded and rusted. Thus, the corrosion resistance of the stainless steel matrix is reduced. Stainless steel pickling process can be applied to all 200, 300, 400 series stainless steel surface treatment. All pickling operations will cause the surface of the stainless steel plate to slightly change the size while removing impurities, so the result is that to a certain extent, the visual brightness of the extinction will even lead to the size reduction. Heat treatment in a vacuum or a good controlled atmosphere, such as bright annealing, eliminates the need for pickling and usually results in a better finish for stainless steel.

Stainless steel cleaning agent oil degreasing, stainless steel materials in the surface treatment must first remove clean grease, cutting fluid, painting compounds and other lubricants, then the stainless steel parts before the surface heat treatment passivation treatment. Stainless steel plates must also be welded before degreasing to avoid carbon precipitation from the picker at high temperatures. Generally speaking, when using stainless steel cleaning agents, as long as the material is soaked at room temperature for about ten minutes, it can get rid of all kinds of oil, the operation is relatively simple, the labor intensity is also very low, and it can be recycled repeatedly, which can significantly reduce production costs.

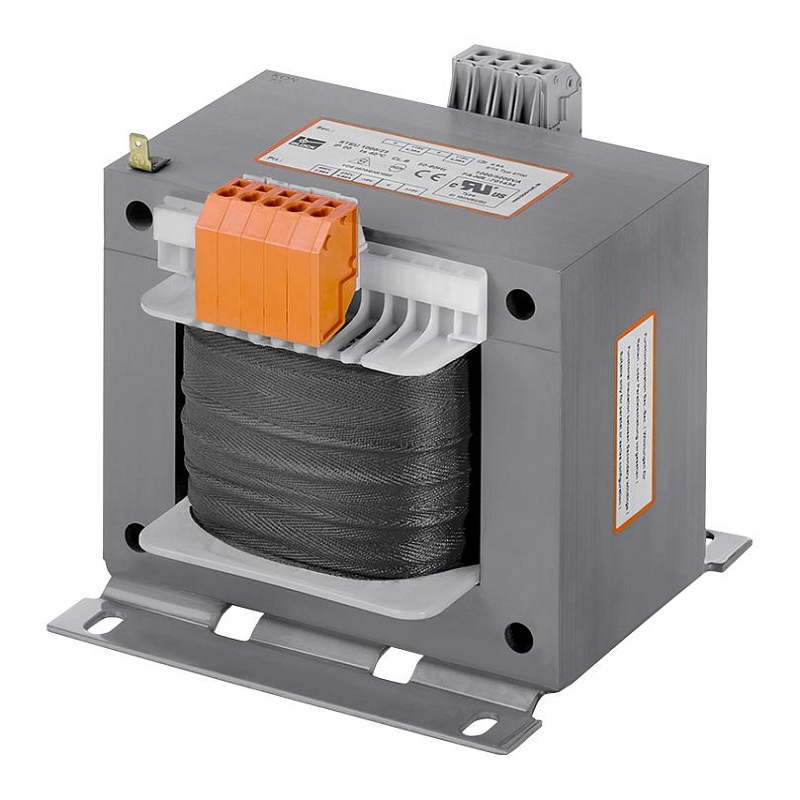

Current demand for transformers at home and abroad

2023-09-21Introduction to the Coating Process of Silicon Steel

2025-11-20Special steel for energy (High strength non-oriented silicon steel)

2024-08-19Application of silicon steel in the field of new energy vehicles

2022-09-26How long can the colored stainless steel plate last without fading?

2022-10-19Current situation and future development trend of Chinese automotive motor iron core market

2024-01-18