Product Name | Pure Titanium Plate Titanium Strips Titanium Coils & Clad Plates |

Grade | TA1G (TA1) /Gr1/TA21(TA2)/Gr2 |

Standard | GB/T3620.1-2016,GB/T3622-2023,GB/T3621-2022,ASTM B265-2020a/s |

Thickness | 0.2-2.0mm |

Width | 1000/1220/1250/1040/1240/1280mm ( standard customization) |

Application |

Processing and production industry(with industry application codes for quick matching) |

Surface | Bright Surface/Frosted Surface/Mixed Bright & Frosted Surface |

Processing | Weldable by various methods

|

Delivery | 30-45 days |

Business Code | Factory Direct Sales |

1.chemical composition(impurity content =<,%):

Grade | Fe | C | N | H | O | Single | other total |

TA0 | 0.15 | 0.10 | 0.03 | 0.015 | 0.15 | 0.10 | 0.4 |

TA1G | 0.20 | 0.08 | 0.03 | 0.015 | 0.18 | 0.10 | 0.4 |

Gr1 | 0.20 | 0.08 | 0.03 | 0.015 | 0.18 | 0.10 | 0.4 |

TA1 | 0.25 | 0.10 | 0.03 | 0.015 | 0.20 | 0.10 | 0.4 |

TA2G | 0.30 | 0.08 | 0.03 | 0.015 | 0.25 | 0.10 | 0.4 |

Gr2 | 0.30 | 0.08 | 0.03 | 0.015 | 0.25 | 0.10 | 0.4 |

2.Mechanical Properties:

Grade | Tensile Strength(Mpa) | Elongation | Hardness(HB) |

TA1G/Gr1 | 240-310 | >=30 | >=105 |

TA2G/Gr2 | 275-450 | >=25 | >=140 |

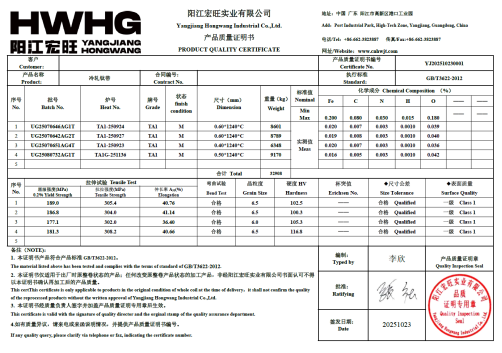

Product Quality Certificate

Product Quality Certificate

Applications:

The pure titanium products independently R&D and produced by Hongwang New Materials Co., Ltd. are suitable for parts operating below 350℃ with low stress, as well as parts stamped into various complex shapes. Typical applications include:

1. Condensers of thermal power plants

2. Marine pipeline systems, valves and pumps resistant to seawater corrosion

3. Chemical heat exchangers, pump bodies and distillation towers

4. Seawater desalination systems and platinum-plated anodes

5. Aircraft frames, skins, engine components, crossbeams

6. Eyeglass frames, plates, electrodes and deep-drawn products

Core Advantages: Why Choose Hongwang Pure Titanium?

1. Superior Inherent Performance: Density is only 60% of steel, with strength comparable to high-quality steel and specific strength far exceeding traditional metals; acid-alkali resistant, seawater corrosion resistant, stable performance under high temperatures, and long-term service without frequent maintenance.

2. Precision Manufacturing & Controllable Quality: Precision rolling with 20-high mills + continuous annealing process optimization ensures flat and bright surface and high dimensional accuracy; full-process quality inspection guarantees each batch meets GB/ASTM/JIS and other international standards.

3. Customized Services for Diverse Needs: Offers wide-width titanium with thickness 0.2-2.0mm, supports sandblasting, slitting, leveling and personalized size customization, meeting application needs for titanium clad plates, chemical heat exchangers, thermos bottles, deep-drawn parts, etc..

4. Safe Protection & Worry-Free Delivery: Three customized packaging options for domestic/export/slitting, featuring multi-layer waterproofing, steel guard ring reinforcement, and baked blue steel strapping, fully protecting products during transportation and ensuring perfect condition upon arrival.

FAQ

Q1.How to select the appropriate grade of commercially pure titanium plate?

A1.Select according to specific application scenarios: A00 for general circulation materials (mesh punching, chemical fillers), B00 for plate heat exchangers, C00 for pipe-making water expansion/shallow stamping products, C10 for deep cooling materials, C20 for eyeglass frames, G10 for electrode plates/spiked plates, F00 for clad plates; the recommended material state for all codes is annealed state M. Contact customer service for precise matching if uncertain.

Q2.What are the delivery states of titanium materials? How to choose the appropriate state?

A2.There are two main delivery states: annealed soft state (code F, suitable for mixed bright/frosted surface applications) and cold-rolled hard state (code Y, suitable for hard-state processing scenarios such as eyeglass frames); annealed state M is preferred for regular general scenarios, while hard state Y can be specified for special processing hardness requirements.

Q3.How can you ensure the quality of your product?

A3.All products have to go through three checks in the whole manufacturing process,it includes production,cutting sheets and the packing.

Q4.About the complaint,quality problem,etc aftersales service,how do you handle it?

A4.We will have certain colleague to follow our order accordingly for each order with professional after-sales service. If any claim happen, we will take our responsibility and compensate as per contract. For better serve our client, we'll keep tracing feedback of our products from clients and that's what make us different from other suppliers. We're customer care enterprise.

HONGWANG SHIPPING PACKING

1.Domestic Packaging

To meet the requirements of long-distance customers and ensure the quality of product transportation and warehousing.

<1>Full sealing with woven waterproof paper

<2>The outer layer of the steel coil is wrapped with 2 layers of corrugated paper

<3>The inner and outer circumferences are wrapped with blue plastic sheets

<4>Inner and outer steel guard rings

<5>Baked blue steel strapping (3 radial, 3axial)

<6>Label and lifting hints

2.Export Packaging

To meet the requirements of sea transportation and ensure the quality of product transportation and warehousing. Full wrapping with steel-plastic film Full sealing with woven vapor-phase waterproof paper.

<1>Full sealing wrapping of the steel coil withplastic film

<2>Full sealing with woven VCI waterproofpaper

<3>Paper corner protection for the inner and ·Wooden strips between strips for separation outer edges

<4>2 layers of corrugated paper applied to the outer circumference of the steel coil

<5>Wrapping the inner and outer circumferences with blue plastic boards

<6>Inner and outer steel protective rings

<7>Blued steel strapping (3 radial straps, 4 axial straps)

<8>Labels and lifting instructions

3.SlittingPackaging

To meet the requirements of long-distancecustomers and ensure the quality of producttransportation and warehousing.

<1>Single stripwrapped with packaging tape (long-length winding)

<2>Inner and outer paper corner protectors

<3>Wooden strips between strips for separation

<4>Bottom with bracket

<5>4 axial strappings

<6>Full sealing and waterproofing with plastic film

-

No Data