Different stainless steel surface treatment processes can make the same material highlight different visual effects and feel characteristics. WuxiHongwang from the design point of view, the company's PVD coating stainless steel sheet uses the following seven kinds of stainless steel surface treatment technology.

1. PVD process

PVD (Physical Vapor Deposition)-Physical vapor deposition refers to the process of transferring atoms or molecules from a source to the surface of a substrate by using a physical process. Its function is to spray some particles with special properties (high strength, wear resistance, heat dissipation, corrosion resistance, etc.) on the matrix with lower performance, so that the matrix has better performance. The basic methods of producing PVD coating stainless steel sheet are vacuum evaporation, sputtering and ion plating (hollow cathode ion plating, hot cathode ion plating, arc ion plating, reactive ion plating, radio frequency ion plating and DC discharge ion plating).

2. Sand blasting (shot blasting)

Sand blasting is to use compressed air as power to form a high-speed jet beam and spray the sprayed materials (copper ore, quartz sand, carborundum, iron sand and sea sand) to the surface of the workpiece to be treated at high speed, so that the surface appearance or shape of the workpiece changes. Sand blasting has a strong application in PVD coating stainless steel sheet technology, such as improving the viscosity of adhesive parts, decontamination, optimizing the surface burr after machining, and matte surface treatment. Sand blasting technology is more uniform and efficient than manual grinding. The stainless steel treatment of this method creates the low-key and durable features of PVD coating stainless steel sheet.

3. Chemical treatment

Chemical treatment: it is a general term for the method of forming a layer of stable compound on the surface of stainless steel by chemical or electrochemical treatment. As we often say, electroplating is treated by electrochemistry. Acid solution and anodic dissolution (electrolysis) are used alone or in combination to remove rust, and phosphate treatment, chromate treatment, blackening and anodic oxidation are used to form a protective film on the surface of PVD coating stainless steel sheet. This method can achieve complex patterns and create retro or modern design requirements.

4. Mirror treatment

Mirror treatment of stainless steel is simply to polish the surface of PVD coating stainless steel sheet, and the polishing methods are divided into physical polishing and chemical polishing. Local polishing can also be carried out on the surface of PVD coating stainless steel sheet, and the polishing grades can be divided into ordinary polishing, ordinary 6K, fine grinding 8K and super fine grinding 10K. Mirror gives people the feeling of high-grade simplicity and fashionable future.

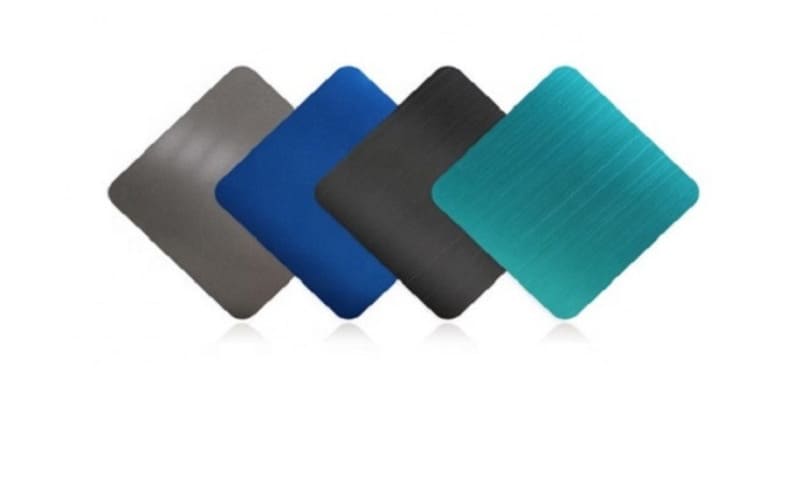

5. Surface coloring

Stainless steel coloring not only endows PVD coating stainless steel products with various colors, increases the variety of products, but also improves the wear resistance and corrosion resistance of products. There are many methods of surface coloring, which are systematically divided into: 1. Chemical oxidation coloring method; 2. Electrochemical oxidation coloring method; 3. Ion deposition oxide coloring method; 4. High temperature oxidation coloring method; 5. Gas-phase cracking coloring method.

6. Surface drawing treatment

Drawing process Drawing is a common technique for stainless steel products, which can be made into straight lines, random lines, threads, ripples and twists according to the decoration requirements. Stainless steel surface drawing gives people super good hand feeling, delicate luster, wear-resistant surface and individual texture effect. It is widely used in electronic equipment, kitchen appliances and mechanical equipment.

7. Spraying

Painting of stainless steel is substantially different from the coloring mentioned above. According to the different materials of PVD coating stainless steel sheet, some painting may damage the oxide layer on the surface of PVD coating stainless steel sheet. However, spraying can achieve stainless steel products with different colors by simple process, and can also use different spray paints to change the feel of stainless steel. Like our daily stainless steel cups, spraying technology will be adopted.

Tag:stainless steel ,PVD Coating Stainless Steel Sheet, Surface pattern processing technology, surface treatment, the surface of PVD

Do you know the stainless steel water pattern sheet?

2022-11-09Stainless steel surface treatment process, do you like it?

2022-10-15Have you ever noticed the colors of spring?

2023-04-06Nickel Cost Rises,Stainless Steel Producers’ Profit margin extruded

2020-09-29Coastal Life,Can’t without Stainless Steel Swimming Pool Fence

2020-10-28The importance of pickling passivation of stainless steel

2023-09-19