As a core material in key fields such as aerospace and medical applications, titanium alloys have long faced the challenge of balancing yield strength and uniform plasticity — an increase in strength is often accompanied by a sharp decrease in plasticity, which has become the main bottleneck limiting performance improvement. Recently, Professor Shen Jianghuas team from the School of Aerospace at Northwestern Polytechnical University, in collaboration with Professor Ma Qian and other international teams from RMIT University in Australia, has made a major breakthrough in the design of α-β titanium alloys. The related results have been officially accepted by "Nature Communications".

The first author of the paper is Yang Yahui, a PhD student at the School of Aerospace, Northwestern Polytechnical University. The corresponding authors are Professor Shen Jianghua from Northwestern Polytechnical University and Professor Ma Qian from RMIT University.

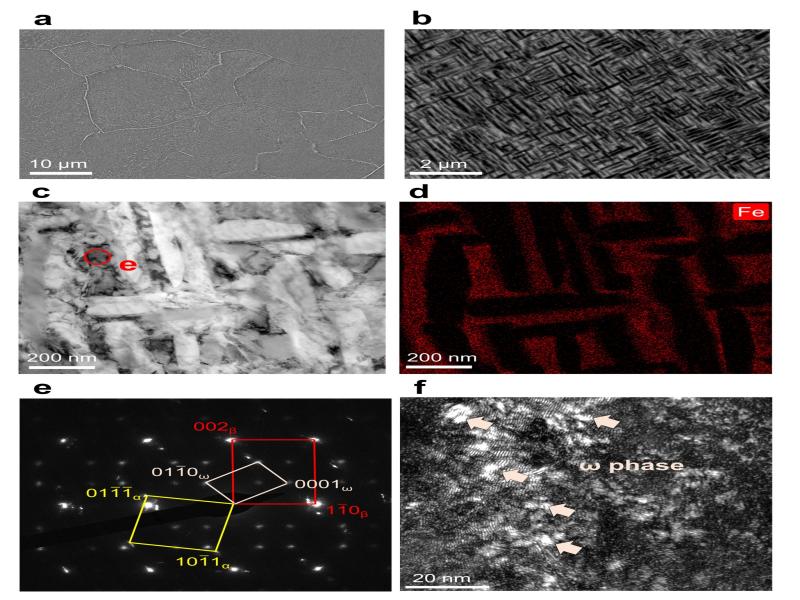

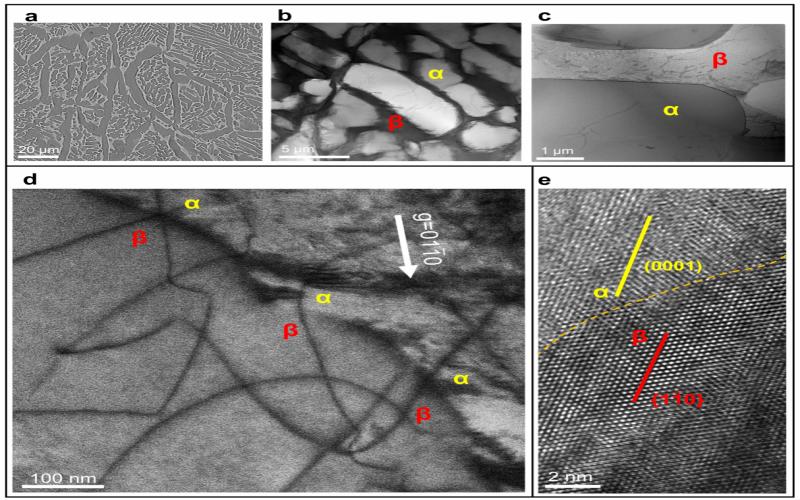

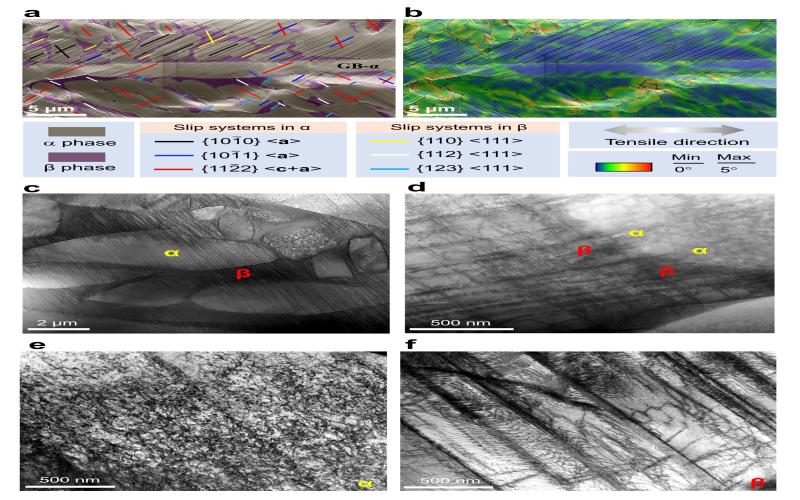

The research team innovatively proposed a dual strategy of 'composition regulation + microstructure engineering.' By increasing the oxygen content to over 0.40%, they successfully activated the <c+a> slip systems on the prismatic planes of the α phase, providing a critical pathway for plastic deformation. At the same time, through Ti-O-Fe alloy design, laser powder bed fusion additive manufacturing, and annealing treatment, they constructed an α-β lamellar microstructure with coherent interfaces, enabling continuous transmission of dislocations across phase boundaries.

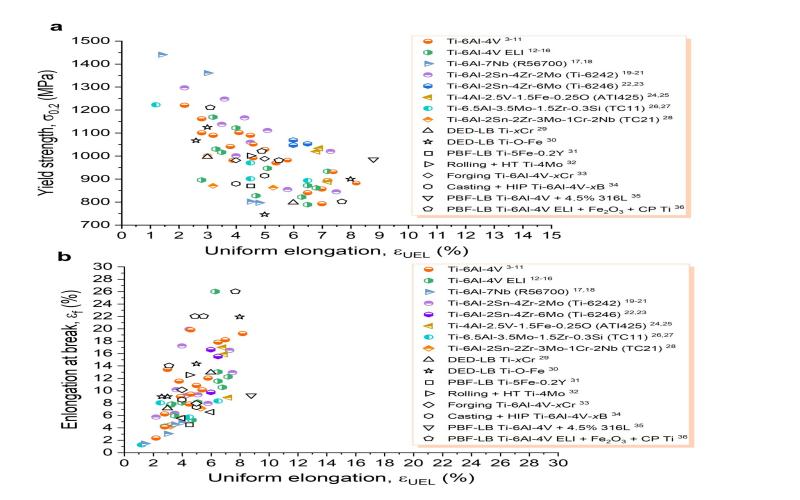

Experimental results show that the Ti-0.45O-4Fe alloy achieves a uniform elongation of over 14% and a total elongation exceeding 27% at a yield strength of ≥980 MPa. The Ti-0.5O-5Fe alloy surpasses a yield strength of 1075 MPa while maintaining a uniform elongation of over 13%, far exceeding the performance levels of existing similar alloys. This breakthrough not only addresses the long-standing strength-plasticity trade-off dilemma but also establishes a novel design paradigm for high-oxygen titanium alloys, providing a new approach for the development of high-performance structural materials.

The innovative design concept of this research can be extended to other alloy systems, with broad application prospects. Its low-cost, high-strength, and high-toughness characteristics are expected to support the lightweight and service safety enhancement of key aerospace structural components, as well as performance upgrades in critical products such as high-end medical implants and consumer electronics.

Overview of frequency transformer types

2023-10-13Import and export data of stainless steel in China from January to November 2022

2023-01-04NEW RECORD! 2019 Global SS Slab Production Reached 52.4 Million MT!

2020-11-03Do you really understand European standard stainless steel grades?

2025-12-24The iron loss caused by cutting silicon steel sheet is evaluated by thermal measurement

2024-06-29A kitchen knife can't pat garlic? Stainless steel has a temper!

2022-07-20