Don't be fooled by the technical names! Here's the simple truth: Grain-oriented silicon steel is "disciplined" - it has a clear magnetic direction, making it perfect for transformers. Non-oriented silicon steel is "versatile" - equally efficient in all directions, which is why motors love it!

Quick Guide to the Differences:

1. Different Structures

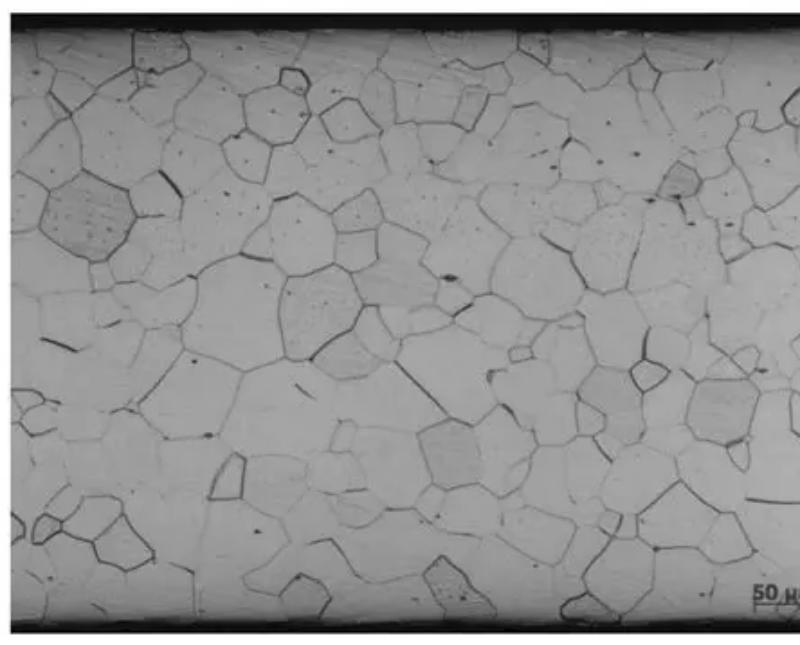

Grain-oriented silicon steel: Crystals align in one direction like an orderly queue → high magnetic permeability, low core loss

Non-oriented silicon steel: Crystals scatter randomly like a crowd → balanced performance in all directions

2. Silicon Content

Grain-oriented: High silicon content (>3%) with added "inhibitors"

Non-oriented: Lower silicon content (0.5%~3%), simpler production process

3. Main Applications

Grain-oriented: Ideal for transformers (especially high-voltage, large energy-efficient transformers)

Non-oriented: Used in motors, generators, AC compressors, and vehicle drive motors

4. Differences in Cold-Rolled Products

Cold-rolled grain-oriented: High-performance, smooth surface, strong magnetism, complex manufacturing (includes advanced Hi-B versions)

Cold-rolled non-oriented: Practical choice, stable dimensions, attractive surface, high filling factor

Motors rely on "non-oriented" steel, while transformers depend on "oriented" steel. Understand this, and you'll never get lost!

Zhaoqing Hongwang was Approved to set up Guangdong Doctor Workstation

2020-09-10Get In Hongwang's Dream Car Together

2022-03-28New Anti-Finger Print Stainless Steel with Better Properties

2020-09-10THE NEW YEAR MESSAGE OF 2021 FROM CHAIRMAN CUHUI,DAI

2021-01-04South China Stainless Steel Sheet Stereo Intelligent Warehouse Online!

2020-09-102020 HONGWANG FINAL NEW SURPRISE,THEY ARE COMING!

2021-01-07