At present, we are facing a critical period of the transformation of the global energy structure, which brings new opportunities to the special steel in the energy field, but at the same time, it also puts forward higher requirements for material properties and green low-carbon. In order to sort out the current situation of special steel for energy use in China and guide the way for future development, World Metal Guide and CITIC Pacific Special Steel Group jointly launched a series of reports on "Special Steel for energy use", discussing the product research and development, technological innovation, typical applications and future prospects of special steel for energy use from the perspective of production, education and research, and accelerating the advancement of special steel industry for energy use to high-end.

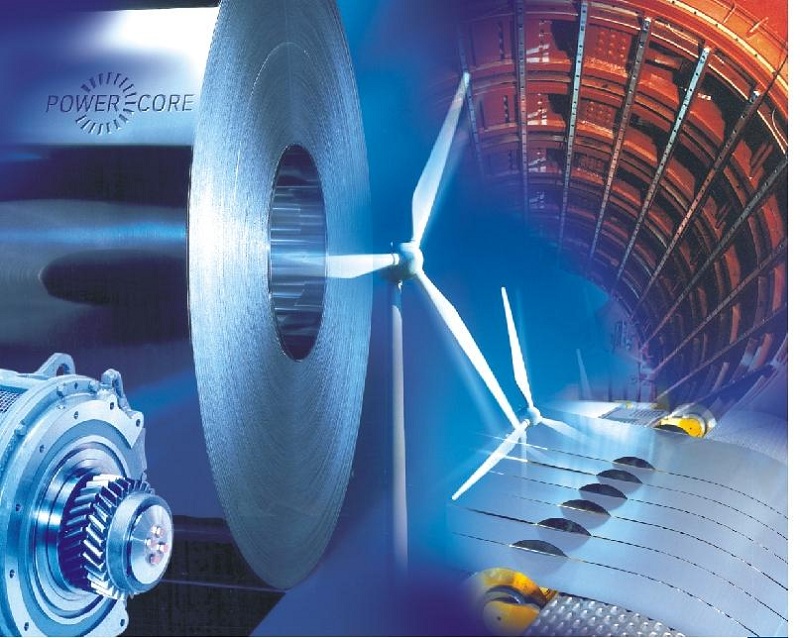

In the context of "double carbon", all walks of life are accelerating the reduction of carbon emissions. As one of the key industries to achieve the "double carbon" goal, the reduction of carbon emissions in the steel industry is not only to reduce carbon emissions in the production process, but also to significantly reduce carbon emissions in various applications through the application of advanced steel materials. As far as the automobile industry is concerned, the global automobile industry is currently transitioning to new energy and accelerating the realization of electrification, of which China's new energy vehicles are developing most rapidly. The rapidly rising production and sales of new energy vehicles have strongly driven the installed demand for drive motors. Practice has proved that the use of high-grade non-oriented silicon steel to make motor stators and rotors can not only improve the efficiency of the drive motor of new energy vehicles but also further reduce carbon emissions, which helps to save energy and reduce carbon throughout the life cycle of steel materials.

01 New energy vehicle drive motor and high strength non-oriented silicon steel

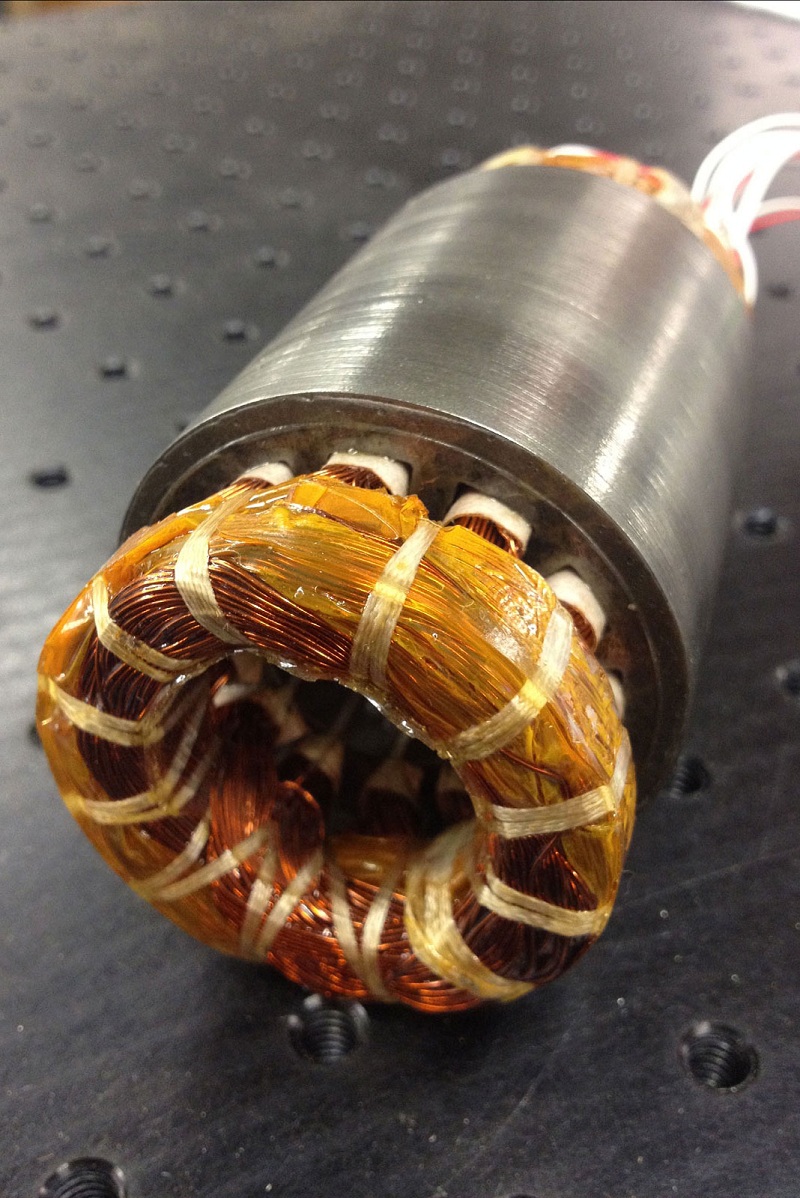

The driving power of new energy vehicles, especially B-class and C-class electric vehicles, is generally above 180kW, and two or more sets of electric drive systems need to be configured. As the proportion of high-end electric vehicles continues to increase, it will drive the installed capacity of new energy drive motors to further increase. With its advantages of high power density, low energy consumption, small size and light weight, permanent magnet synchronous motor is the most widely used in China's new energy vehicles, accounting for 94.4% of the total installed capacity in 2021. The drive motor is one of the three core components of new energy vehicles, and its future development direction is high-speed and high-power. This requires the motor to reduce the volume, weight and iron consumption of the motor as much as possible under the same power, but reducing the volume and weight of the motor will lead to a reduction in motor torque, so it is necessary to increase the motor speed. For example, the speed of the Prius2015 motor almost reached 3 times that of the Prius2004 motor, and the peak torque showed a decreasing trend. Through the combination of high-speed motor and reducer box, the high-speed low-torque input is transformed into low-speed high-torque output, and then the purpose of driving new energy vehicles is achieved.

The high speed and high power of the drive motor also put forward higher requirements for motor materials, especially the fixed rotor core made of non-oriented silicon steel sheets, which not only directly determines the motor power, torque, iron consumption, temperature rise, etc., but also affects the driving range of new energy vehicles. For example, the Nissan Leaf II, which was launched in Japan, North America and Europe in 2018, has a battery capacity of only 40kWh, but a driving range of 400km, which is the same as the Tesla Model S with a battery capacity of 60kWh. This is because the Nissan Leaf II uses a permanent magnet synchronous motor as a drive motor to provide excitation with a permanent magnet, no excitation current is required, so there is no excitation loss, low loss and high efficiency. In addition, the stator core of the Nissan Leaf II drive motor is composed of silicon steel sheets with a thickness of 0.25mm, which reduces iron consumption and further improves motor efficiency. The drive motor core of the 2016 BWM i3 is composed of silicon steel sheets with a thickness of 0.27mm, and the rotor core has a large number of weight reduction holes to reduce the weight of the motor and increase the power density of the motor. Therefore, in order to improve the efficiency and power density of the motor, the silicon steel sheet for the motor has been thinned from the traditional 0.35mm and 0.50mm to 0.25mm and 0.27mm. It is foreseeable that with the increase of motor speed, silicon steel with thinner specifications and lower iron loss will gradually be applied to new energy vehicle drive motors.

The cold-rolled non-oriented silicon steel sheet is the key soft magnetic material which determines the conversion of power and energy. The iron consumption generated in the iron core is an important part of the motor loss, especially when the motor is running at high speed, the proportion of iron consumption in the total loss increases significantly. In the UHF state, eddy current loss alone accounts for 40th-70% of the total loss, so it requires silicon steel to have as low a high-frequency iron loss as possible, which can not only improve motor efficiency, improve the driving range of new energy vehicles, but also restrain temperature rise and avoid demagnetization of permanent magnets. In the starting and low-speed climbing stages of the vehicle, the motor needs to output huge torque enough to drive the car to start, so it needs to have the highest possible magnetic sensation. In addition, the huge centrifugal forces at high speeds and the demanding constant rotor clearance design also require the rotor material to have a higher yield strength. Therefore, the drive motor of new energy vehicles with high speed and high power density requires the use of cold-rolled non-oriented silicon steel sheets with thinner specifications (≤0.35mm), lower high-frequency iron loss, higher magnetic induction and high yield strength.

Due to the long process flow, narrow process window and difficult production of high-strength non-oriented silicon steel products for new energy vehicle drive motors, there are fewer enterprises with large-scale and stable production capacity in the world. At present, non-oriented silicon steel for new energy vehicle drive motors can be produced internationally by Japan JFE, Japan Steel, South Korea Posco and other enterprises, while only a few enterprises such as Baosteel, Shougang and TiSCO can be mass-produced in China. With the rapid development of new energy vehicles, the market demand for non-oriented silicon steel for new energy vehicle drive motors at home and abroad is strong, and some enterprises at home and abroad have built new production lines for non-oriented silicon steel for new energy vehicle drive motors. This paper will introduce the product, technical route and market situation of high strength non-oriented silicon steel sheet for new energy vehicle drive motor at home and abroad, and provide reference for the development and production of non-oriented silicon steel products for new energy vehicle drive motor.

How much impact does the China EU investment agreement have on stainless steel? What about tariffs?

2021-01-06Look forward to the next flower with Hongwang.

2023-06-08The application of magnesium oxide in electrical steel

2023-09-01Influence of silicon steel material on transformer performance

2024-11-22The status of colored stainless steel decorative sheets in decorative materials

2020-11-26Stainless steel plate - an important cornerstone in the industrial field

2024-06-20