The first thing to be clear about is that no one material is optimal for every application, and trade-offs must be made between cost, weight, size, and other factors. In addition, the lamination process after manufacturing has a great influence on the performance of the designed core. Material selection criteria include cost, permeability, electromagnetic loss and saturation flux density. Permeability and core loss vary with flux reversal frequency (in Hertz) and flux density, and in some applications the shape of the hysteresis curve becomes important. Every available material is optimized for one or more of these properties and less than perfect in others.

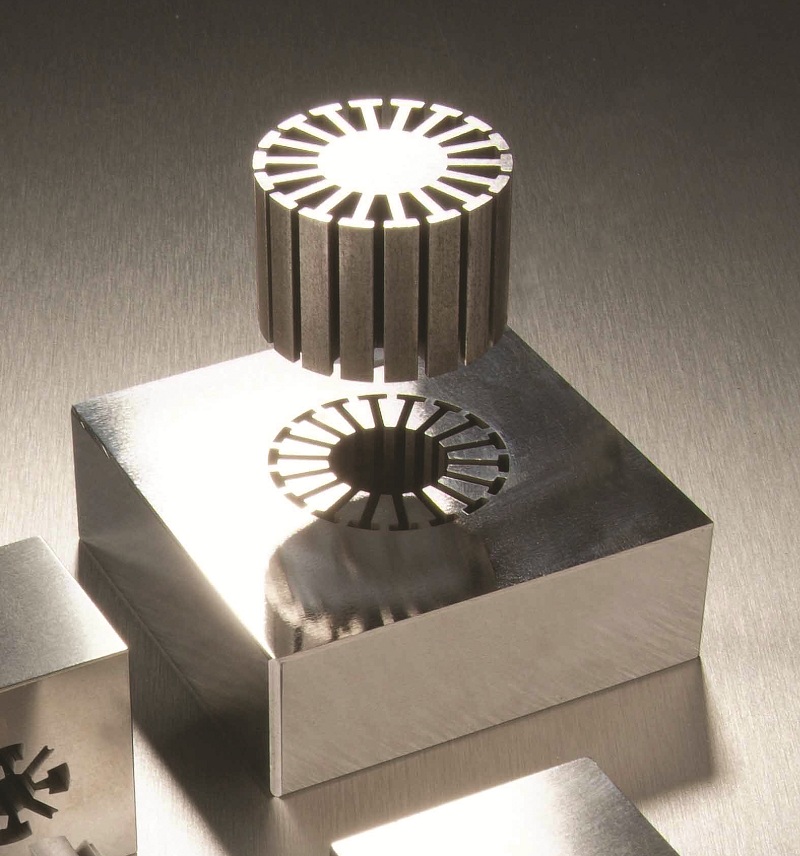

At present, the most commonly used material for motor core is cold-rolled laminated steel, which is the lowest cost material for batch applications, and easy stamping and low tool wear help reduce the cost of finished lamination. In applications where high core losses (DC poles, low duty cycle, etc.) and low-cost end equipment are acceptable, carbon steel should be considered, of course, the magnetic and mechanical properties of this material are one of the more decisive factors. The thinner the material, the lower the high-frequency eddy current loss, and the efficiency of the motor is improved. This in turn means lower power consumption and thus a longer transmission distance range at the same power capacity level.

The sheet is thinner, the production time is longer, and the productivity is reduced. In the case of a motor with a stator outer diameter of 250 mm and a lamination height of 120 mm, the thinner the sheet thickness, the more lamination is required to achieve the desired total height. The stamping speed varies between 220 strokes/min (for 0.25mm thick sheets) and 250 strokes/min (for 0.35mm thick sheets), depending on sheet thickness. Taking into account scrap, downtime and system availability, production will be between 32 piles (0.35 mm) and 19 piles (0.25 mm) per hour, which represents a 1.7 times increase in stamping time.

Strong electric motors can be produced with a large number of grades of steel, and when choosing a drive motor operated purely by electric means, the primary question is how much can be saved by using higher quality, thinner, and therefore more expensive electrical steel. Even a relatively small difference in efficiency can affect the battery's range and therefore the required (very expensive) battery capacity.

In addition, extremely thin core steel can improve the efficiency of high-speed motors, especially the efficiency of the stator, but in the rotor, it is often necessary to achieve very high strength rather than thinner thickness, and special joining processes, such as all-surface bonding, make the rotor design also have a positive impact on efficiency.

Thin is not always good, and the use of core steel must be looked at very differently from the overall perspective of machinability, cost, application areas, efficiency and other technical factors in motor design, with many conditions clearly showing favor for the use of steel of different thicknesses.

Stainless steel plate - an important cornerstone in the industrial field

2024-06-20Exploring the Diversity and Advantages of Stainless Steel

2025-10-21Future electric vehicle iron core market research

2023-09-05The difference between 304 and 316 stainless steel

2021-05-19Stainless steel surface treatment process- Mirror treatment

2020-11-192,700 Tons Steel Transported from Ningxia to Countries along “Belt and Road”

2020-11-09