Current Location : Home > News > Industry News > 304 polished stainless steel pipe and 304 brushed stainless steel pipe

304 polished stainless steel pipe and 304 brushed stainless steel pipe

Time:2021-08-25

Source:Wuxi Hongwang

Hits:411

Polishing and wire drawing are actually processing requirements for the surface roughness of 304 stainless steel pipes. Today I will share with you what is the difference between 304 stainless steel polished pipe and 304 stainless steel wire drawing pipe?

304 polished stainless steel pipe

304 stainless steel pipe polishing is divided into mechanical polishing and chemical polishing

1.304 stainless steel pipe mechanical polishing is divided into mechanical grinding and fluid grinding

The 304 stainless steel pipe is mechanically ground, and a grinding wheel is installed on the grinding machine. During grinding, the grinding wheel rotates at a high speed, and the high temperature generated by the friction between the steel pipe surface and the grinding wheel improves the plasticity of the pipe surface. Under the action of the grinding force, the surface of the substrate is plastically deformed, pressing the convex part and flowing to the concave surface, reducing the surface Roughness. In addition, the chemical composition of the 304 stainless steel grinding tube and the surrounding medium during grinding chemically react with the metal being ground during grinding. For the great grinding effect and grinding, the surrounding medium is also divided into coarse sand and fine sanding 3 Kind. Coarse sand uses 180#--320# thousand impeller to the surface effect of the pipe surface after processing. Fine sand is the surface effect after processing the pipe surface with 320#-600# thousand impeller. The mirror light is ground by the combination of a thousand impeller wheel, hemp wheel and cloth wheel, so that the tube surface has the effect of mirror luster. The advantage of this method of grinding is that the equipment is relatively simple, easy to operate, and does not require chemical auxiliary agents. The disadvantage is that the 304 seamless light pipe cannot be internally polished. If it is handled improperly, scratches are likely to occur, which will result in greater time and labor costs.

304 stainless steel pipe fluid grinding, fluid grinding uses high-speed flowing liquid and the abrasive particles carried by it to clean the surface of the stainless steel pipe to achieve the purpose of grinding. Commonly used methods include abrasive jet processing, liquid jet processing, fluid dynamic grinding, fluid magnetic grinding and so on. Hydrodynamic grinding is driven by hydraulic pressure to make the liquid medium carrying abrasive particles flow back and forth across the surface of the steel pipe at high speed. The medium is mainly made of special compounds (polymers) with good fluidity under low pressure and abrasive materials. The abrasive materials can be silicon carbide powder. The advantage of this method of grinding is that it has high brightness and can internally grind 304 stainless steel square pipes. The disadvantage is that the square pipes need to be sprayed one by one, and the work efficiency is low.

2. 304 stainless steel pipe chemical polishing can be divided into: electrolytic polishing ep and chemical polishing cp

1) Electrolytic polishing of 304 stainless steel pipe EP is the anodic corrosion of metal parts under specific conditions. This process improves the micro-geometry of the metal surface, reduces the micro-roughness of the metal surface, and achieves the purpose of brightening the surface of the part.

2), 304 stainless steel pipe chemical grinding CP is the chemical attack of metal parts under specific conditions. In this erosion process, the metal surface is eroded and smoothed by the solution, and a brighter surface is obtained. The surface roughness is generally several tens of microns.

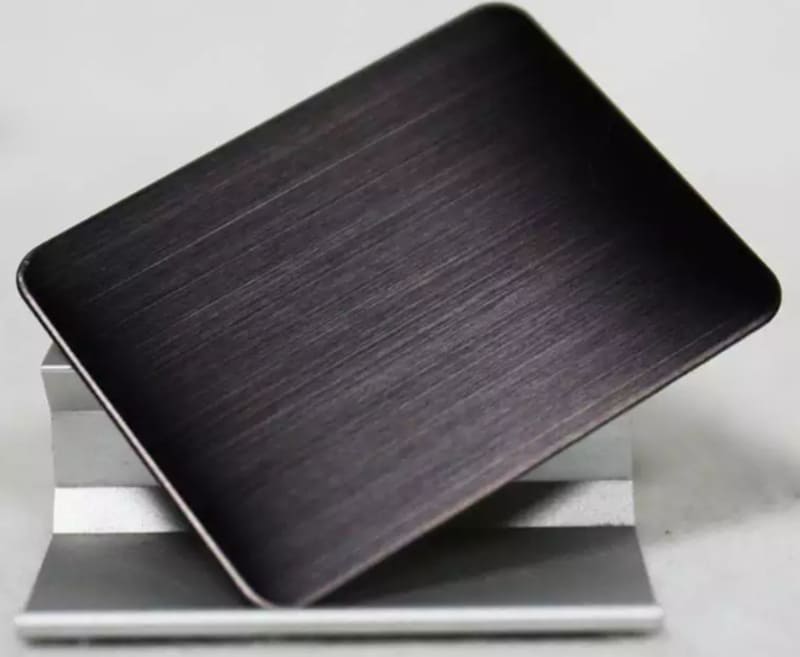

304 brushed stainless steel pipe

304 stainless steel pipe drawing is a kind of metal processing technology. It is a popular surface treatment technology in the stainless steel and aluminum products industry today. It is the best treatment for 304 stainless steel pipe drawing. 304 stainless steel pipe drawing generally has several effects: straight line, snow pattern, nylon pattern. Straight line texture is an uninterrupted texture from top to bottom. Generally, the front and back movement of the fixed drawing machine workpiece is used. The snow pattern is currently the most popular. It is composed of dots with regular dots. It can be used with insect sandpaper to achieve the effect and smooth the part. The nylon pattern is composed of lines of different lengths. Because the nylon wheel is soft in texture, it can grind uneven parts to reach the nylon pattern.

Hongwang Investment Group is an enterprise specializing in the production of stainless steel cold-rolled coils and stainless steel surface finishing products. The products have a complete range of products and excellent quality. They have received unanimous praise from customers at home and abroad. If you have any needs in this regard, please contact us and look forward to Cooperation with you!

Related News

Common stainless steel 316 and 316L difference

2024-05-06The Role of Transformers in Renewable Energy

2024-11-30How to distinguish stainless steel pipe is 201 or 304

2023-02-02Process characteristics of 304 stainless steel sheet

2020-12-28Urban rail transit construction to create a large market for stainless steel

2022-12-28Cold rolled non-oriented electrical steel with high reduction rate

2023-12-29